Head & sill can filler, G) intermediate horizontal, Installation – EFCO 904 Series User Manual

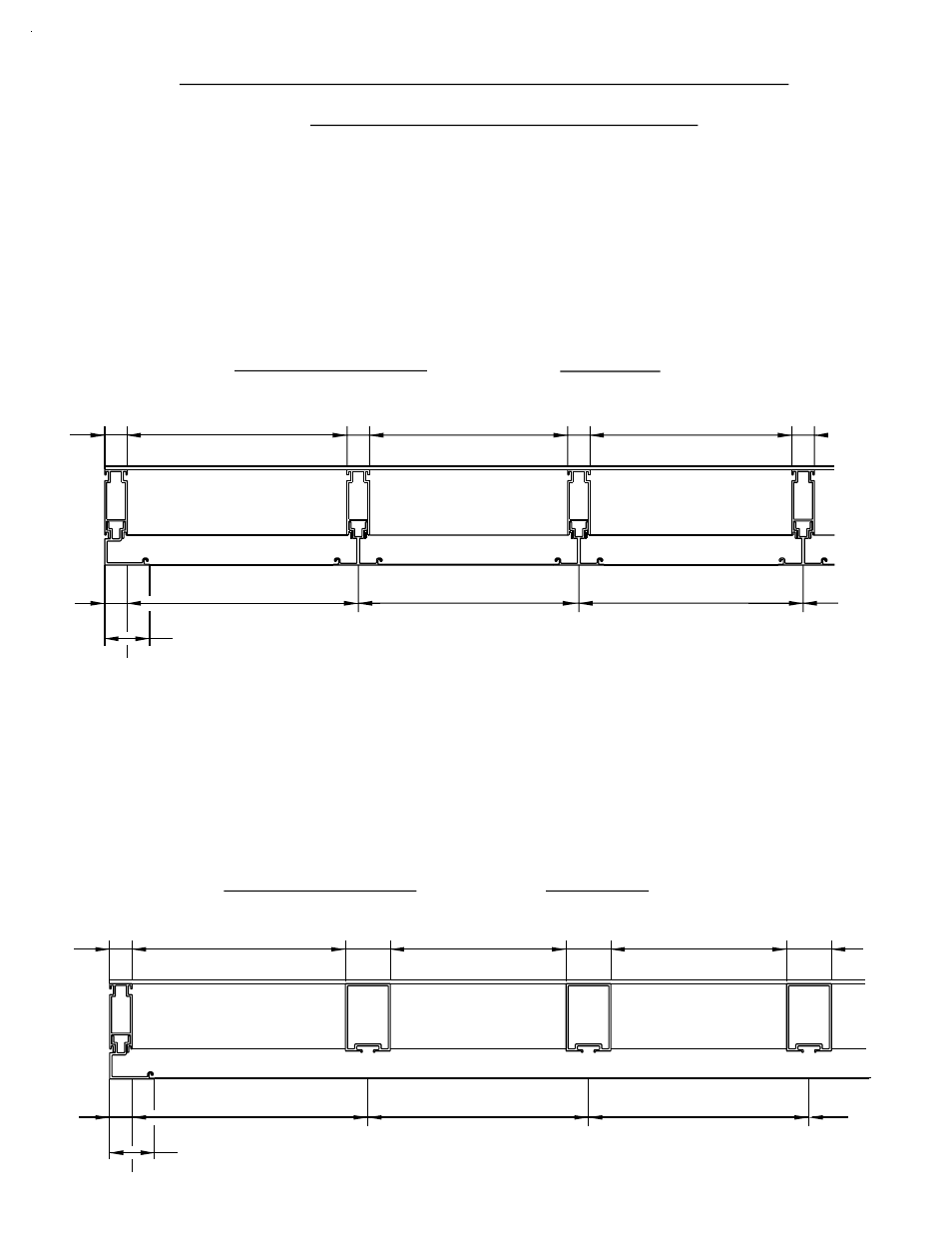

Page 18: Fig. 8, 1) can filler cut lengths, 2) can filler cut lengths, Fig. 7, Head and sill can filler, Minus 2, Minus 1

(Head and sill cans run through. Can fillers run mullion to mullion,

and mullion to jamb.)

1"

C

L

1"

MULLION

CENTER LINE

2"

CAN FILLER

CUT LENGTH

CAN FILLER LENGTH

CENTER LINE

MULLION

C

L

[FIG. 8]

CAN FILLER LENGTH

2"

CENTER LINE

C

L

MULLION

2"

DPS 7/2001

C

L

2"

Step 1) Determine center lines of each vertical mullion.

to center line of first mullion minus 1 1/2".

and mullion to jamb.)

1) CAN FILLER CUT LENGTHS

SECTION III D - FABRICATION

to center line of first mullion minus 2".

Step 1) Determine center lines of each vertical mullion.

2) CAN FILLER CUT LENGTHS

Step 3) Mullion to mullion cut length = Center line to center line

Step 2) Jamb to first mullion cut length = End of head/sill can

(Head and sill cans run through. Can fillers run mullion to mullion,

Step 2) Jamb to first mullion cut length = End of head/sill can

Step 3) Mullion to mullion cut length = Center line to center line

MULLION

1"

L

C

minus 2".

CENTER LINE

2"

1"

CAN FILLER

CUT LENGTH

minus 1".

CAN FILLER LENGTH

MULLION

MULLION

(BUTT GLAZED SYSTEMS)

CENTER LINE

C

L

[FIG. 7]

CENTER LINE

C

L

1"

CAN FILLER LENGTH

1"

C

L

1"

HEAD AND SILL CAN FILLER

(CAPTURED MULLION SYSTEMS)

PAGE 16