Head & sill can fabrication, 2) butt gla, E) vertical in – EFCO 904 Series User Manual

Page 15: Fig. 2, Step 3), Step 2), Fig. 1, Step 1), Head and sill can

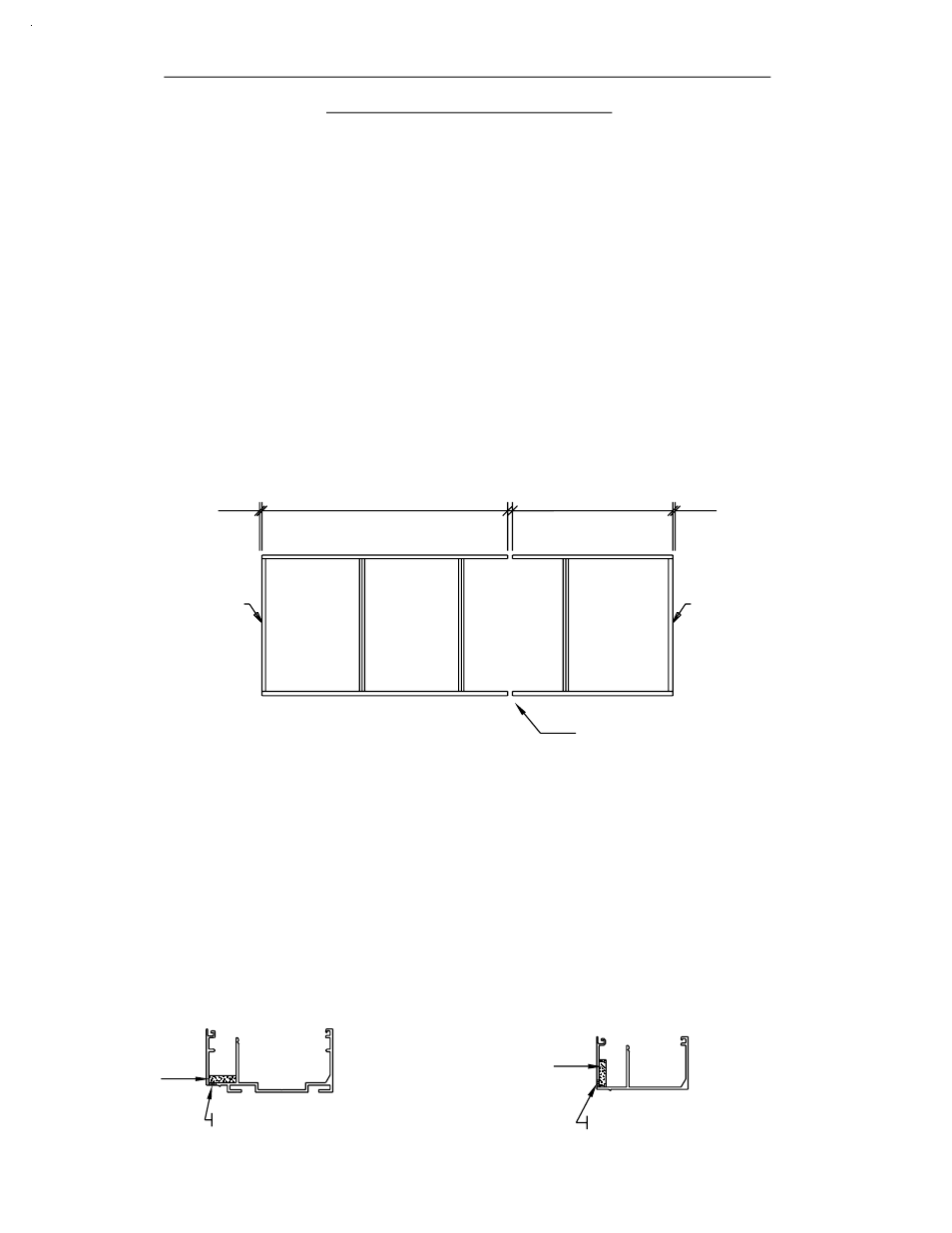

includes 2 color covers, installed prior to weeping and anchoring.

NOTE: Sill cans with riser legs are bottom weeped and sill cans with flat

903/904

bottoms are face weeped.

HOLE IN BOTTOM

See Fig. 3 on Page 14.

HCW6

[FIG. 2]

HCW6

901/902

HOLE IN FACE

DPS 7/2001

INCLUDES CAPTURED AND BUTT

the center of the nearest lite and adjust cut lengths accordingly.

NOTE: Expansion/splice joints are required in elevations that exceed

Measure the opening to determine the cut length of the head

JAMB

"2" color covers that are being used.

and sill frame components. Allow for shims if applicable.

Cut head and sill cans to frame width. This includes any

20 FT. TYPICAL

HEAD & SILL LENGTH

20’-0" in width. Plan for expansion/splice joints to fall at

Drill 1/4" weep holes in sill can 6" from jambs and 48" on

center or if the length is less than 48", drill (1) per lite. This

STEP 3)

JAMB

SHIM

STEP 2)

OPT.

1/4"

[FIG. 1]

EXPANSION/SPLICE

JOINT

SHIM

20 FT. MAXIMUM

1/2"

OPT.

1/4"

SECTION III C - FABRICATION

STEP 1)

GLAZED MULLION SYSTEMS

PAGE 13

HEAD AND SILL CAN