Carrier EVERGREEN HFC-134A User Manual

Page 18

18

Table 10 — Compressor Fastener Identification

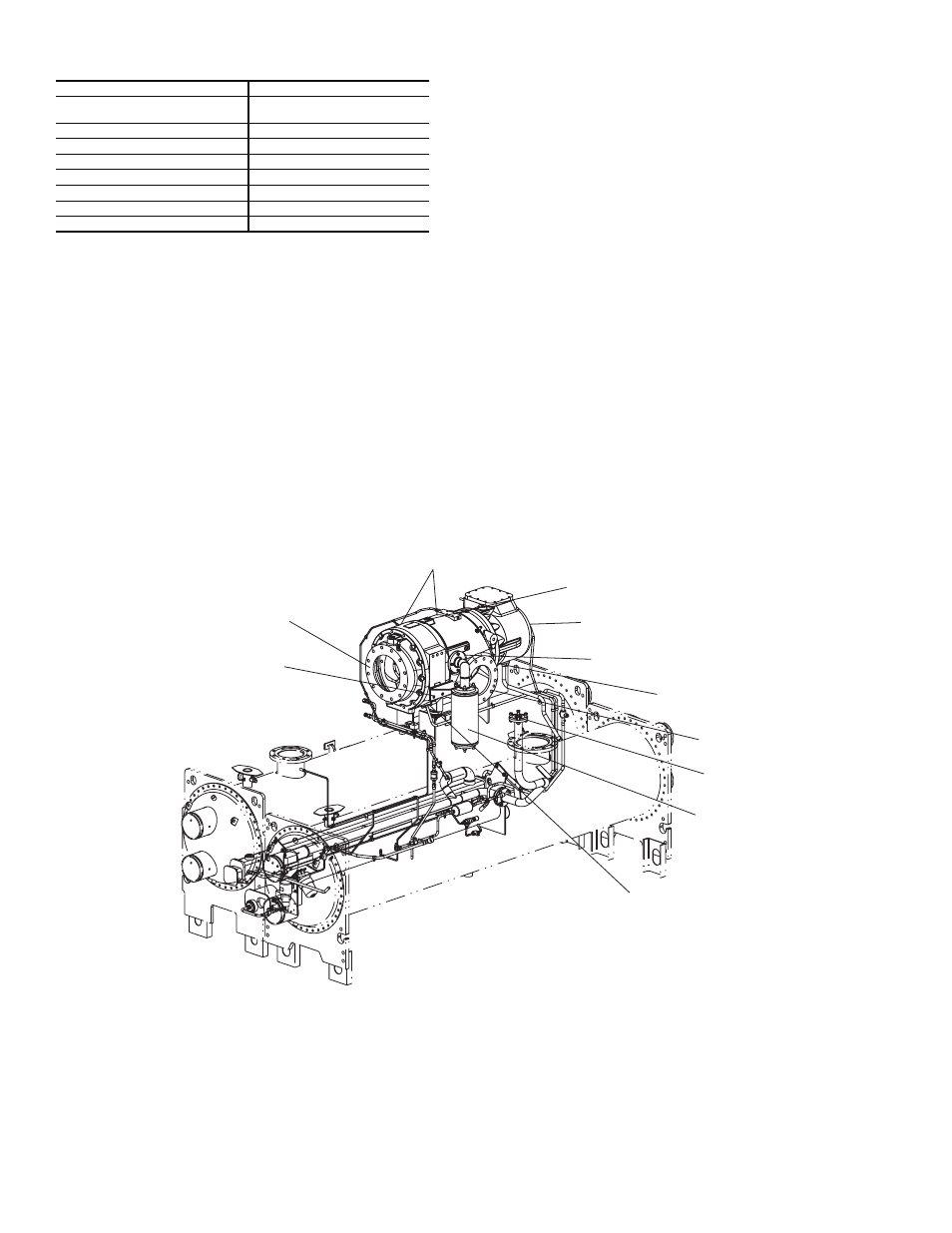

1. Disconnect the oil supply line in two places (Fig. 23).

Cap the oil lines and fittings.

NOTE: Compressor oil lines and fittings between the oil filter

and compressor must be kept extremely clean to prevent

obstruction of the compressor inlet bearing oil orifice. Cap all

orifice lines and fittings during disassembly. The compressor

inlet bearing oil orifice is located at the lubrication block on

top of the compressor.

2. Disconnect the motor cooling inlet flange, the motor

cooling drain flange, optional economizer vapor line

flange, and bearing oil drain flange (Fig. 23). Remove the

economizer muffler bracket.

3. Brace the end of the discharge pipe assembly closest to the

compressor if it has not already been removed. Place an oil

pan under the compressor flange to collect oil that may

have accumulated in the discharge pipe assembly. Unbolt

the discharge pipe assembly from the compressor. It may

also be necessary to loosen the bolts that attach the dis-

charge pipe assembly to the condenser.

4. If the cooler has been removed, rig the suction elbow and

unbolt the suction elbow at the compressor and vaporizer

vent line flanges (see Fig. 12). If the cooler is still in

place, it may be necessary to loosen the bolts that secure

the suction elbow to the cooler.

5. Carefully remove the perforated insulation cutouts that

cover the compressor lifting points. See Fig. 23. Replace

the lifting shackle thread protector after the compressor is

re-installed to prevent insulation adhesive from fouling

the threads.

6. Rig the compressor with lifting eyelets installed in the

two M30 threaded holes provided in the top of the com-

pressor housing (Fig. 23). Use only M30 forged eye bolts

or M30 hoist rings with a sufficient working load limit to

safely lift the compressor. The rubber vibration isolators

may pull out of the compressor mounting bracket when

the compressor is lifted off of the condenser. Applying

leak detection soap solution to the outside of the vibration

isolators will make it easier to press the isolators back

into position.

7. Cover all openings.

NOTE: To reassemble, follow steps in reverse order. Connect

sensors and cables after major components have been secure to

reduce the risk damaging them.

COMPRESSOR FASTENERS

SIZE

Discharge Pipe Assembly to

Compressor Discharge Flange

1 in.-8 Grade 5 Hex Head

Suction Elbow to Compressor Inlet

7

/

8

in.-9 Grade 5 Hex Head

Compressor Mount to Condenser

3

/

4

in.-10 Studs (A-449)

Economizer Line

5

/

8

in.-11 Grade 8 Hex Head

Motor Cooling, Motor Drain, Oil Drain

M 12x1.75 Grade 10.9 Socket Head

Compressor Lifting Points (2)

M30x3.5 Threaded Holes

Stator Housing Lifting Point

M30x3.5 Threaded Hole

Discharge Housing Lifting Point

M30x3.5 Threaded Hole

ECONOMIZER

MUFFLER

BRACKET

DISCHARGE

PIPE ASSEMBLY

BOLTING

FLANGE

OIL SUPPLY LINE

FITTINGS

M30 COMPRESSOR LIFTING

SHACKLE HOLES

MOTOR COOLING INLET FLANGE

ECONOMIZER VAPOR

LINE FLANGE

MOTOR COOLING

DRAIN FLANGE

SUCTION ELBOW

FLANGE

VAPORIZER VENT

LINE FLANGE

ECONOMIZER

MUFFLER

(OPTIONAL)

BEARING OIL

DRAIN FLANGE

Fig. 23 — Compressor Removal

a23-1572