Carrier EVERGREEN HFC-134A User Manual

Page 16

16

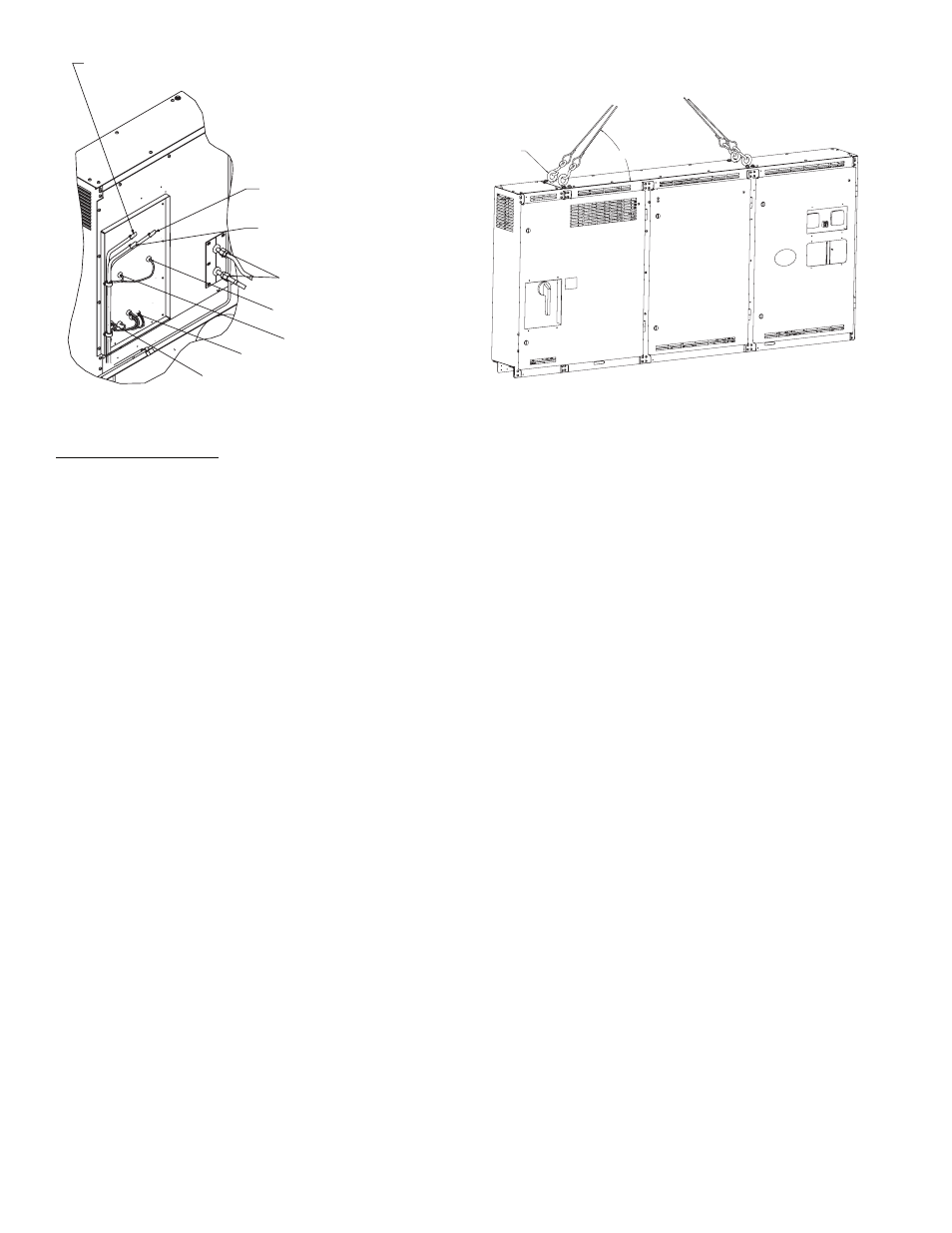

Lifting the Control Center — Care should be used to prevent

damage due to dropping or jolting when moving the control

center. A fork truck or similar means of lifting and transporting

may be used. Sling in a manner that will equalize the load at the

pickup points. Use a spreader bar if the angle of the sling is less

than 45 degrees relative to horizontal. Do not jolt while lifting.

Use the following procedure to lift the control center.

1. Remove the rubber hole plugs in the top of the control

center and fully thread in 4 eyebolts or swivel hoist rings

(see Fig. 21). Lifting hardware must have

3

/

4

in.-10 x 2 in.

long threads and must have a working load limit of at

least 6000 lb (2722 kg). Typical eyebolts are Chicago

Hardware (size 28) or Grainger (P/N 5ZA63).

2. Attach a sling to the four lifting eyebolts. Make certain

that the angle of the sling is not less than 45 degrees

relative to horizontal.

3. Using an overhead or portable hoist (minimum 2 ton

rated capacity), attach a free-fall chain to the sling

secured to the drive. Take up any slack in the chain.

4. Rig the control center and remove the bolts that secure it

to the VFD mounting brackets on the condenser (see

Fig. 21).

5. Confirm that welding procedures comply with local

Pressure Vessel Codes before removing a portion of the

VFD support bracket from the condenser. Custom brack-

ets should be fabricated if part of the VFD supports must

be cut off of the condenser to reduce the width of the

condenser assembly. Clamp ¼-in. plates over both sides

of the VFD bracket and drill two pairs of holes that

straddle the line along which the VFD brackets will be

cut. This will allow the VFD brackets to be reinstalled

and welded in their original position.

NOTE: To reassemble, follow steps in reverse order. Connect

sensors and cables after major components have been secured

to reduce the risk damaging them. (See Fig. 22.)

REMOVE THE DISCHARGE PIPE ASSEMBLY FROM

THE CONDENSER

NOTE: For steps 1 through 6 refer to Fig. 12.

The condenser relief valve and relief valve vent piping should

be removed if they will interfere with discharge pipe assembly

rigging.

1. Remove the discharge pipe assembly relief valve and

relief valve vent piping.

2. Disconnect the compressor discharge temperature sensor.

3. Disconnect the compressor discharge pressure sensor and

remove the high discharge pressure switch sensor.

4. Rig the discharge pipe assembly and remove the bolts

from the compressor discharge and condenser inlet

flange. Note the position and orientation of the discharge

isolation valve on the condenser inlet flange.

5. Remove the discharge pipe assembly.

6. Cover all openings.

NOTE: To reassemble, follow steps in reverse order. Connect

sensors and cables after major components have been secured

to reduce the risk of damaging them.

OIL HEATER CONDUIT ASY

OIL PUMP CONDUIT ASY

VAPORIZER HEATER CONDUIT ASY

OIL RECLAIM

ACTUATOR CABLE

VFD COOLING LINE

O-RING FACE SEAL

COUPLINGS

VFD COOLING

SOLENOID CABLE

TEMPERATURE SENSOR

CABLES

PRESSURE SENSOR

CABLES

Fig. 20 — Control Panel Back

a23-1571

45° MIN

LIFTING

EYEBOLT

3/4 IN. - 10 x 2 IN. LIFTING EYEBOLT WITH

SHOULDER OR SWIVEL HOIST RING

6000 LB (2722 KG) WORKING LOAD LIMIT

TYPICAL — CHICAGO HARDWARE P/N 28

GRAINGER P/N 5ZA63

Fig. 21 — Control Center Lifting Points

a23-1561