Separate machine components – Carrier EVERGREEN HFC-134A User Manual

Page 13

13

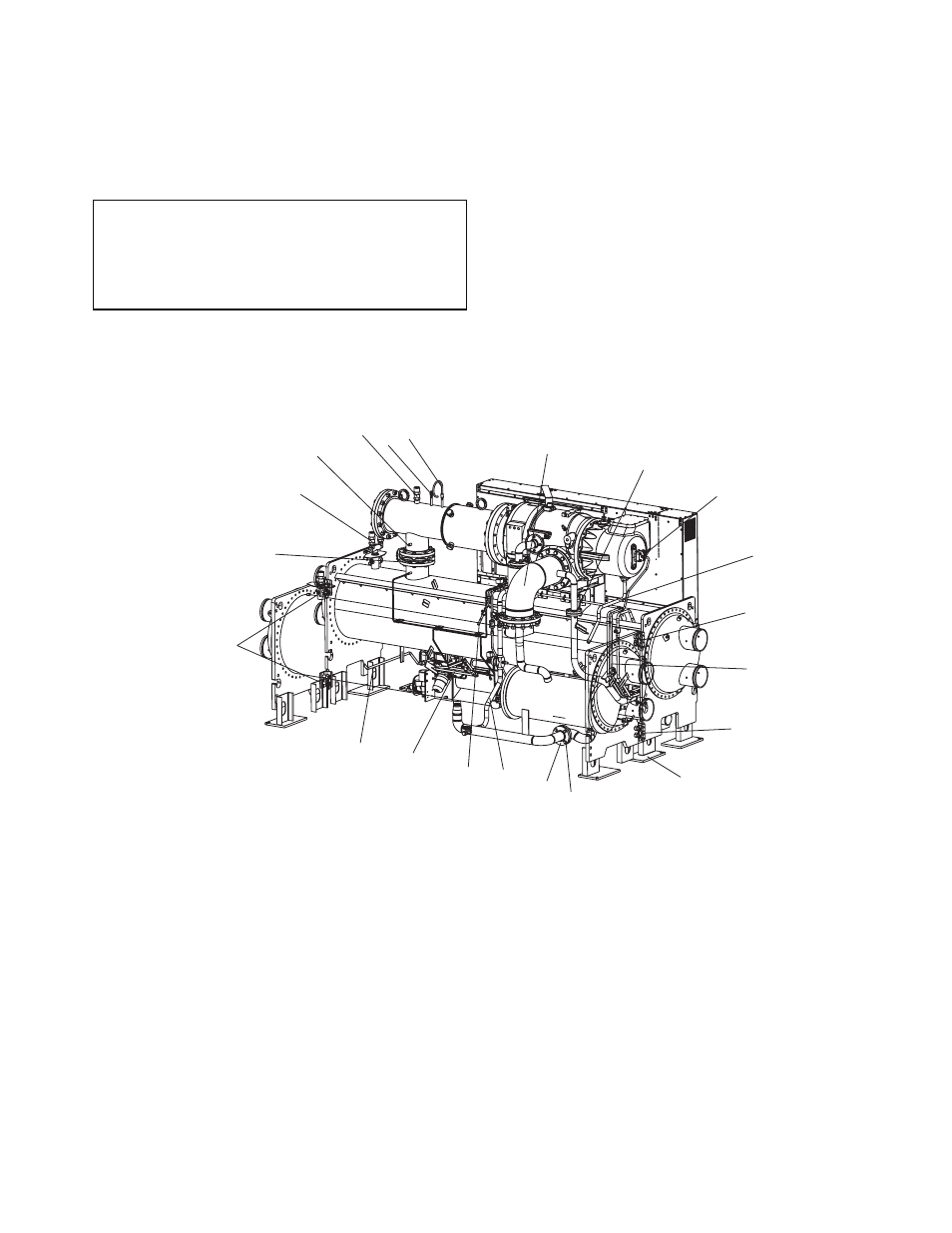

Separate Machine Components —

The design of

the 23XRV allows for disassembly at the job site so that

individual components may be moved through existing door-

ways. Use the following procedures to separate the machine

components.

Suggested locations to cut piping will minimize the width of

the condenser/economizer assembly.

SEPARATE COOLER AND CONDENSER

NOTE: For steps 1 through 13 refer to Fig. 12. The cooler has

been removed from the picture to show the pipes and lines that

must be cut.

Check that the holding charge has been removed from the

chiller.

1. Place a support plate under each tube sheet to keep each

vessel level.

2. Remove cooler relief valve and relief valve vent piping.

3. Cut the motor cooling refrigerant drain line.

4. Rig the suction elbow and disconnect the compressor

suction line at the cooler and compressor. Remove bolts

from the vaporizer vent line flange.

5. Cut the VFD cooling drain line.

6. Cut the oil reclaim line(s).

7. Cut the hot gas bypass line between the HGBP (hot gas

bypass) solenoid valve and the cooler feed line.

8. Unbolt the cooler liquid feed line near the economizer or

condenser float chamber at the flanged connection.

Temporarily secure the in-line economizer orifice plate

(economized chillers only) to the economizer flange (see

Fig. 12).

IMPORTANT: If the cooler and condenser vessels

must be separated, the heat exchangers should be kept

level by placing a support plate under the tube sheets.

The support plate will also help to keep the vessels

level and aligned when the vessels are bolted back

together.

19

18

17

16

15

14

5

13

12

11

10

9

8

7

5

6

5

4

3

2

1

1 — Suction Elbow (Unbolt)

11 — VFD Cooling Drain Line

2 — Vaporizer Vent Line (Unbolt)

12 — Oil Reclaim Line (Cut)

3 — Motor Cooling Line (Unbolt)

13 — Vaporizer Hot Gas Return Line (Cut)

4 — Motor Cooling Drain Line (Cut)

14 — Discharge Isolation Valve (Optional)

5 — Tubesheet Mounting Bracket

15 — Condenser Relief Valves (Unscrew)

6 — Bearing Oil Drain Line

16 — Discharge Temperature Sensor

7 — Support Plate

17 — Discharge Pipe Assembly Relief Valve (Unscrew)

8 — In-Line Economizer Orifice Plate

18 — Discharge Pressure Sensor

9 — Cooler Liquid Feed LIne (Unbolt)

19 — Discharge Pressure Switch

10 — Hot Gas Bypass Line (Cut)

Fig. 12 — Cooler/Discharge Pipe Assembly Removal

a23-1560