Great Plains YP4025F-1670 Operator Manual User Manual

Page 41

Great Plains Manufacturing, Inc.

Operating Instructions

37

2014-09-08

401-571M

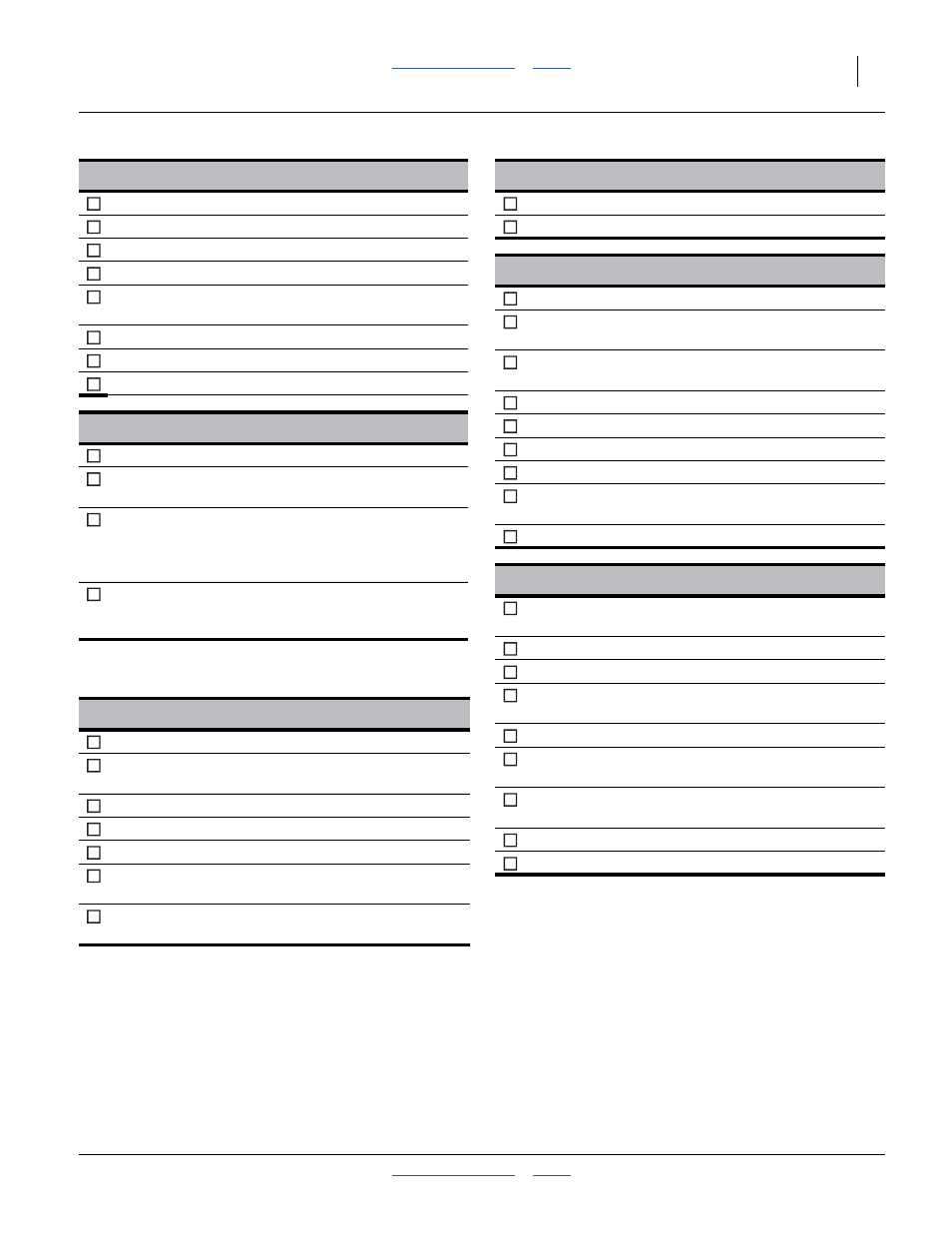

Mechanical Checklist

Page

Tongue height preset on 3-point

Planter unfolded

Tongue front latch hook engaged

28

Transport locks moved to storage

31

Caster locks set to FIELD

(extreme hillsides only)

36

Side-to-side level at gauge wheels

Marker initial length set

Marker disc angle set

Electrical Checklist

Page

Verify electrical hookups solid

Check seed monitor terminal and observe

any diagnostic messages

a

With hydraulic circuits in Neutral, check

switches and indicator lights on Clutch

Folding Module switch panel. Confirm

Master OFF.

-

Verify that, when planter is lowered, radar

speed sensor is pointed at ground, at an

angle approximately 35

°

below horizontal.

b

a.

Refer to monitor manual

b.

Refer to sensor documentation

Air System Checklist

Page

Manifold to seed box or hopper seal

-

Add 1 cup of seed lubricant to each air box,

prior to first use, and prior to loading seed

Seed loaded

Tube gates turned on to correct rows

No air leaks (except from seed box)

-

Hose routings - no sags, no pinches (check

wing-folded & field positions)

-

Hoses fully connected to meters and

locked

-

Frame Mounted Checklist

Page

Row cleaner depth setting

Coulter depth and alignment

Row Units Checklist

Page

Preset depth handles alike

Preset down force springs alike, except in

tracks.

71

Set all unit-mounted coulters to

1

⁄

4

inch

shallower than opener blades

Check coulter alignment to row

Check closing wheel alignment

Set press wheels alike.

Engage meter coupling for all desired rows

Check action and contact of side depth

wheels (25P only)

Check wheel scraper gaps (if installed)

80

Treatments (Options) Checklist

Page

Confirm Clutch Folding Module

“Fert.Pump” switch OFF

Check tractor-mounted components

a

Ground drive wheel, chain

PFC2000 or PFC1600: Execute Tank Cart

Checklist

b

Check for correct orifice plates

c

Fill system with 100 gallons of water, and

check for leaks

-

Check all row unit lines connected, free of

kinks, and discharge tube/nozzles clear

-

Inlet and hose valves open

SmartBox system loaded, powered up

a.

Check supplier manual for tanks and pump. Check fertilizer

section of monitor manual.

b.

See PFC2000/PFC1600 Manual.

c.

Check Seed Rate manual, and manual for fertilizer pump

system.