Troubleshooting, Maintenance, Troubleshooting maintenance – Great Plains YP4025F-1670 Operator Manual User Manual

Page 187

Great Plains Manufacturing, Inc.

Appendix R - Row Pro

183

2014-09-08

401-571M

Troubleshooting

Maintenance

Check the air filter as per manufacturer recommendation.

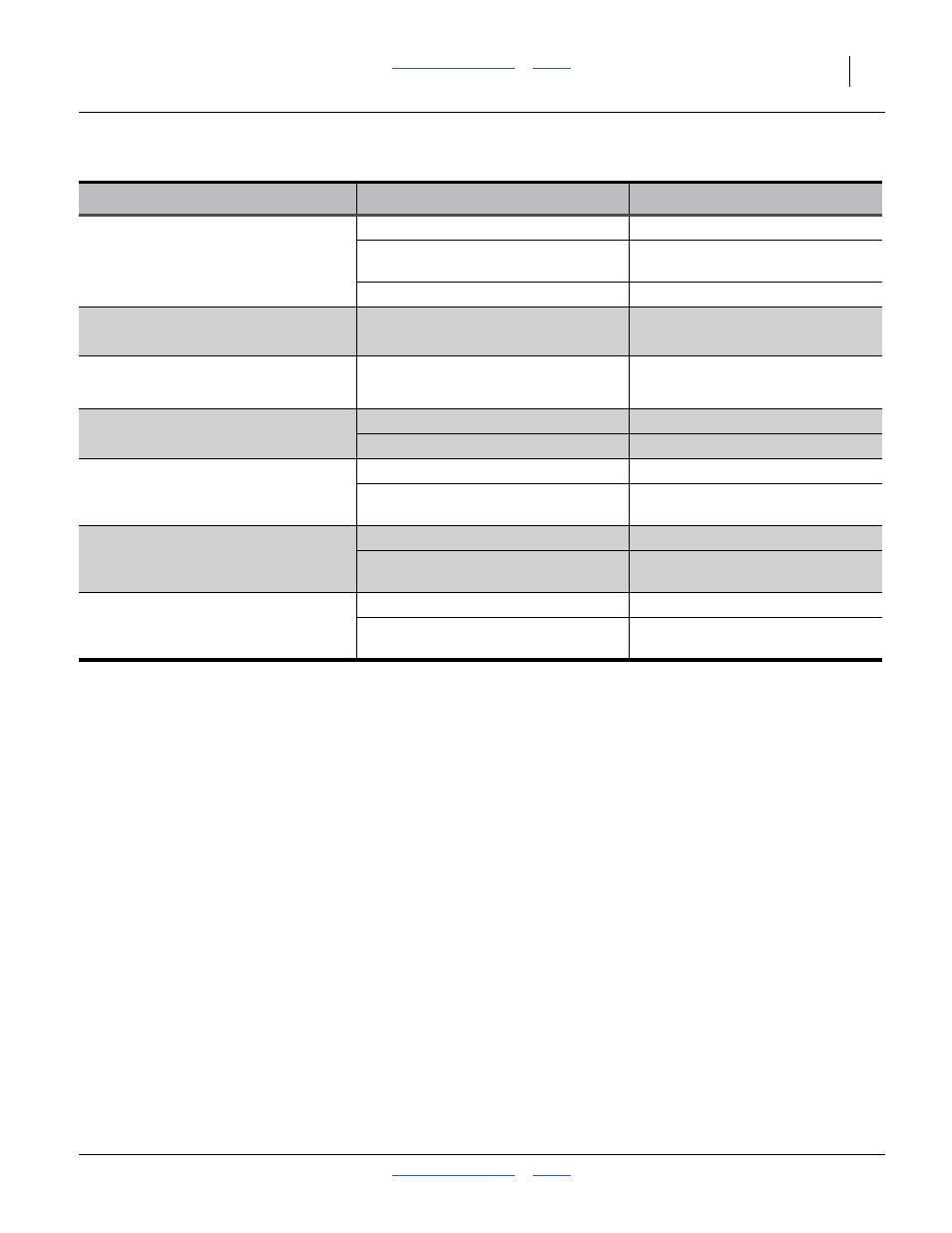

Problem

Cause

Solution

Compressor won’t turn on

Switch turned “off”.

Turn switch “on”.

Poor electrical connection.

Clean connections and

reassemble.

Fuse blown.

Replace fuse (60A).

Compressor won’t turn off (runs

continuously)

Section opener valves are installed in

reverse.

Install opener valves correctly.

Compressor cycles more than

normal

Water build-up in air tank.

Drain tank to keep reserve volume

at proper size.

Erratic down pressure reading

Poor electrical connection to load cell. Clean connection and reassemble.

Load cell malfunction.

Replace load cell.

Persistent “high” alarm

Row unit spring tension too high.

Lower spring tension.

Air leak preventing cylinders from

holding pressure.

Fix leak.

Persistent “low” alarm

Row unit spring tension too low.

Raise spring tension.

Air leak preventing cylinders from

holding pressure.

Fix leak.

System won’t hold air pressure

Pinched/torn hose.

Replace hose.

Hose not pushed into quick connect

fitting far enough.

Push hose in until fully seated.