Warning – Great Plains V-300F Operator Manual User Manual

Page 40

V-300, V-300F

148-057M

6/29/2006

38

d.

Tighten the idler sprocket on the fertilizer final

drive chain

Move idler sprocket back into place so chain has 6 mm

(1/4-inch) slack.

Refer to Figure 40

4.

To change driver/driven ratio, loosen and slide idler

sprockets out of chain. Remove lynch pins from

shafts. Place correct sprockets on shafts. Store

sprockets not used on ends of shafts. Reinstall chain

and slide idlers back into place so chain has 6 mm

(1/4-inch) slack.

!

WARNING

You may be severely injured or killed by being crushed by the

falling implement. Always have transport locks in place and

frame sufficiently blocked up when working on the implement.

5.

Place a sufficient amount of fertilizer to be calibrated

in the hopper to cover the metering system.

Refer to Figure 41

6.

To calibrate, use the crank handle (1) as a key to

push calibration shaft index collar in and rotate to the

left.

NOTE: Decals located next to calibration shaft index col-

lars indicate proper rotation for calibration and field oper-

ation.

Important! This mechanism controls the direction of

fertilizer flow. By rotating the calibration shaft index

collar to the left using the crank handle (1), the opener

hose is blocked off and fertilizer will collect in the me-

tering tray for calibration.

7.

Remove calibration tray (2) from storage position.

Make sure the calibration tray (2) is in the upright po-

sition, locked in place, and clear of any debris.

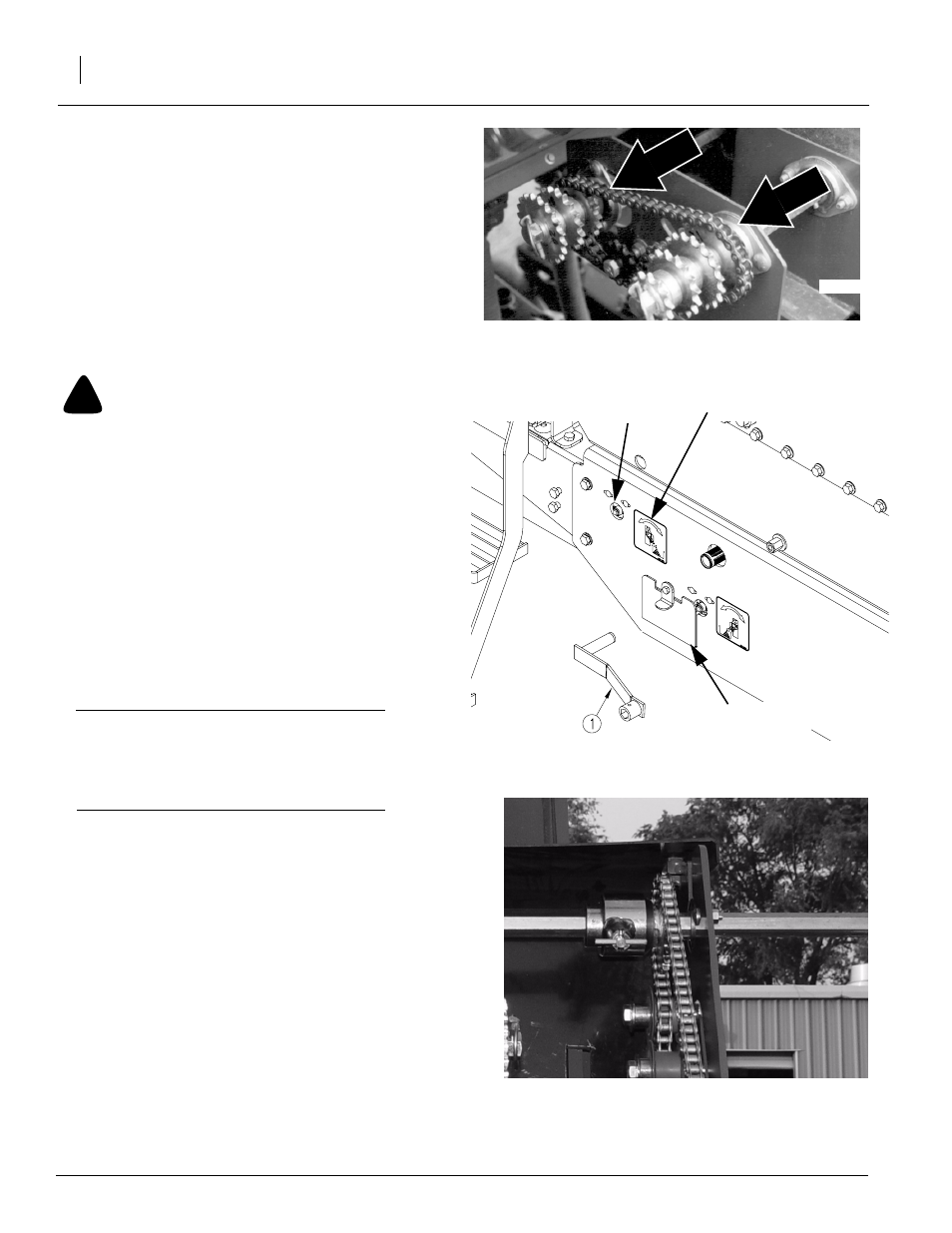

Refer to Figure 42

8.

Disengage the seed drive sprocket by pulling the

plunger pin and turning it to be parallel with the drive

shaft.

9.

Raise the drill to the transport position and install

pins in the transport locks. Refer to Transporting,

“Operating Instructions,” page 22.

Dr

iven

Dr

iver

16378

22611

Figure 40

Driver/Driven Sprockets

Figure 41

Calibration Tray and Crank Handle

23268

Figure 42

Seed Drive Sprocket (shown disengaged)

Calibration

Tray

Decal

Calibration

Shaft Index

Collar