Positioning seed-cup doors, Checking seeding rate, Warning – Great Plains V-300F Operator Manual User Manual

Page 34

V-300, V-300F

148-057M

6/29/2006

32

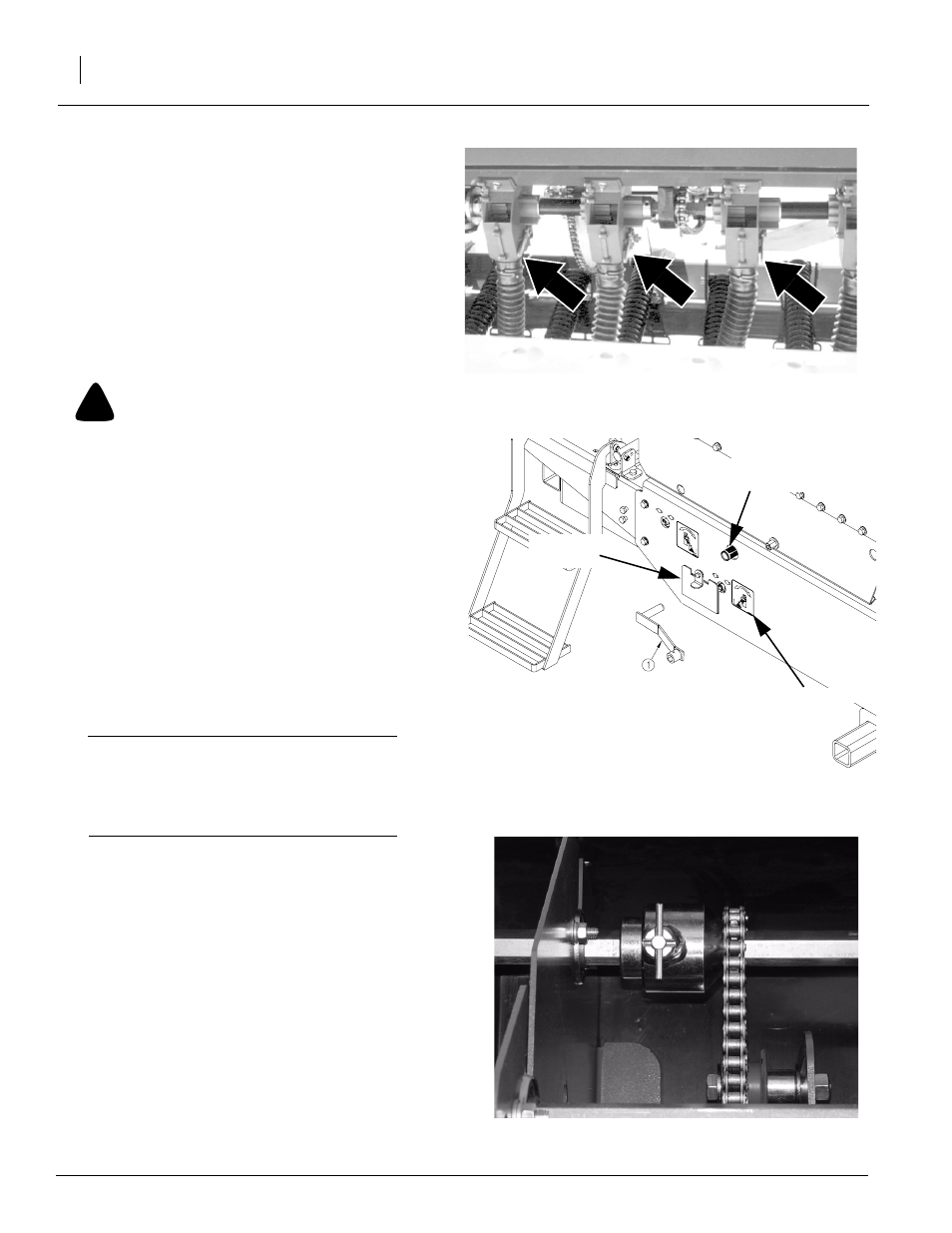

Positioning Seed-Cup Doors

Refer to Figure 34

For wheat and other small seeds, move seed-cup-

door handles to the highest position. For soybeans

and other large seeds, lower handles to second po-

sition. If excessive seed cracking occurs, lower

handles to third position. For seed-cup clean out,

move handles to the fourth, wide-open position.

Make sure all handles are in the same position be-

fore drilling.

Checking Seeding Rate

!

WARNING

You may be severely injured or killed by being crushed

by the falling implement. Always have transport locks in

place and frame sufficiently blocked up when working

on the implement.

1.

Place a sufficient amount of seed to be calibrat-

ed in the hopper to cover the metering system.

Refer to Figure 35

2.

To calibrate, use the crank handle (1) as a key

to push calibration shaft index collar in and ro-

tate to the right.

NOTE: Decals located next to calibration shaft in-

dex collars indicate proper rotation for calibration

and field operation.

Important! This mechanism controls the direc-

tion of seed flow. By rotating the calibration shaft

index collar to the right using the crank handle

(1) , the opener hose is blocked off and seed will

collect in the metering tray for calibration.

3.

Remove calibration tray (2) from storage posi-

tion. Make sure the calibration tray (2) is in the

upright position, locked in place, and clear of

any debris.

Refer to Figure 36

4.

Disengage the fertilizer drive sprocket by pull-

ing the plunger pin and turning it to be parallel

with the drive shaft.

5.

Raise the drill to the transport position and in-

stall pins in the transport locks. Refer to Trans-

porting, “Operating Instructions,” page 22.

16651

22612

Figure 35

Calibration Tray and Crank Handle

Figure 36

Fertilizer Drive Sprocket (shown engaged)

23268

Figure 34

Seed-Cup-Door Handle

Decal

Calibration

Shaft Index

Collar

Calibration

Tray