Changing drive sprockets, Setting seed-rate gauge – Great Plains V-300F Operator Manual User Manual

Page 33

6/29/2006

148-057M

31

Adjustments

2

1

17211

Figure 32

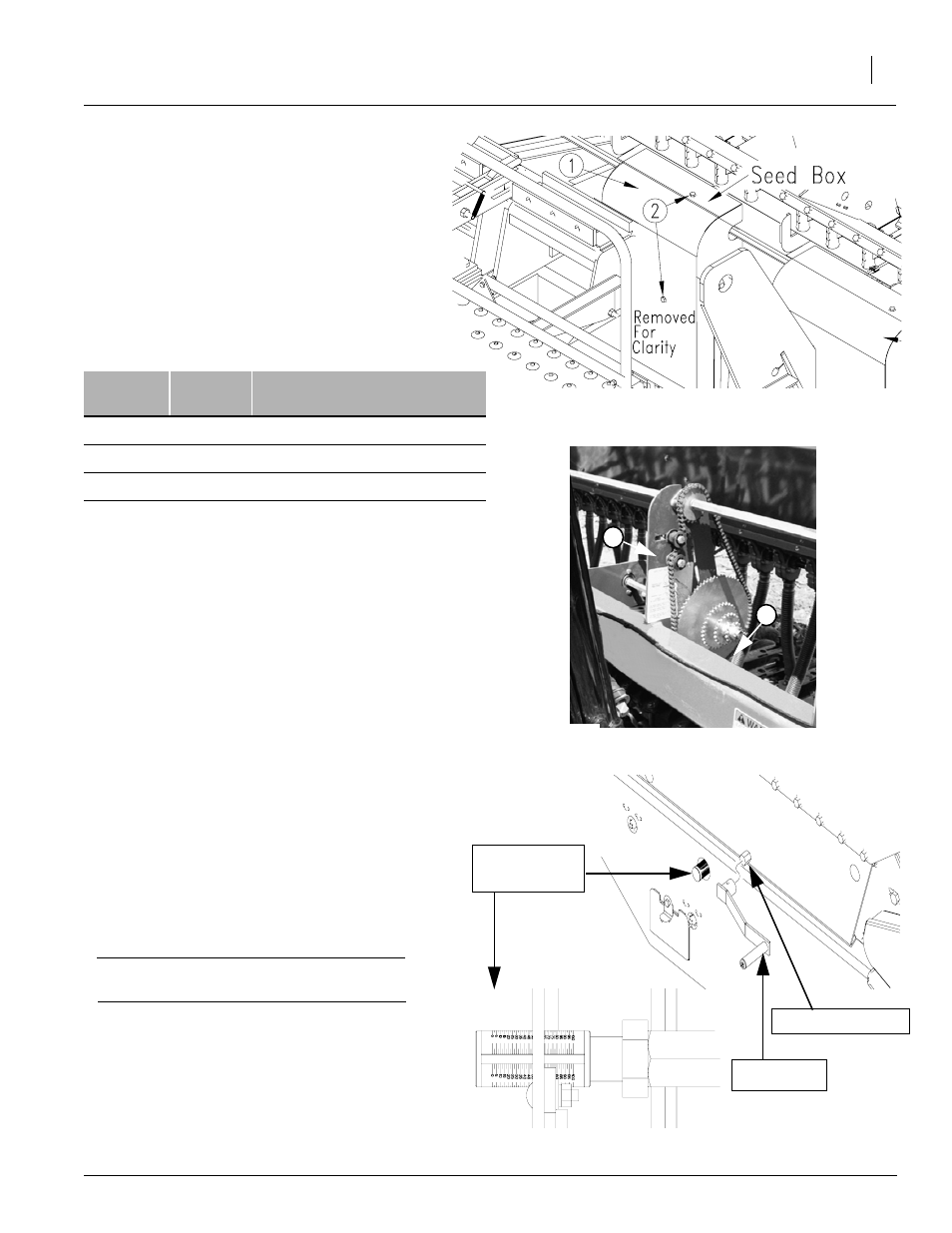

Drive Sprockets

23187

Figure 33

Seed-Rate Gauge

Figure 31

Chain Guard

Seed-Rate Screw

Hand Crank

Seed-Rate

Gauge

23188

Many factors will affect seeding rates including for-

eign material, seed treatment, seed size, field

conditions, tire pressure and test weight. You likely

will need to make minor adjustments. Set and check

the seeding rate using procedures below, then re-

adjust rate as necessary.

Changing Drive Sprockets

For correct drive type, refer to seed-rate charts

starting on page 34. The charts lists drive types as

1, 2, 3 or 4. Refer to the following table for correct-

sized sprocket for each drive type.

Refer to Figure 31

To change drive types, remove the chain guard (1)

by removing bolts (2).

Refer to Figure 32

Loosen idler (1) and remove drive chain. Remove

lynch pin from shaft (2) and re-arrange sprockets on

shaft.

NOTE: Be sure chain is installed with the chain con-

nector link retainer towards the centerline and the

clip opening (split end) faces the opposite way of

the chain travel.

Setting Seed-Rate Gauge

Refer to Figure 33

Important! Read gauge from left-hand side of

plate.

Position seed-rate gauge to setting indicated on

seed-rate charts.

Use the hand crank to rotate the screw located on

the right-hand side of the drill. Rotate the screw one

way or the other until the gauge is at the desired

setting.

Drive

Type

Sprocket

Speed

Type 1

72-tooth

Slowest

Type 2

34 tooth

Two Times Faster Than Type 1

Type 3

23-tooth

Three Times Faster Than Type 1

Type 4

14-tooth

Five Times Faster Than Type 1

23160