Disk scraper adjustment, Harrow adjustment, Leaf spring adjustment – Great Plains V-300F Operator Manual User Manual

Page 30

V-300, V-300F

148-057M

6/29/2006

28

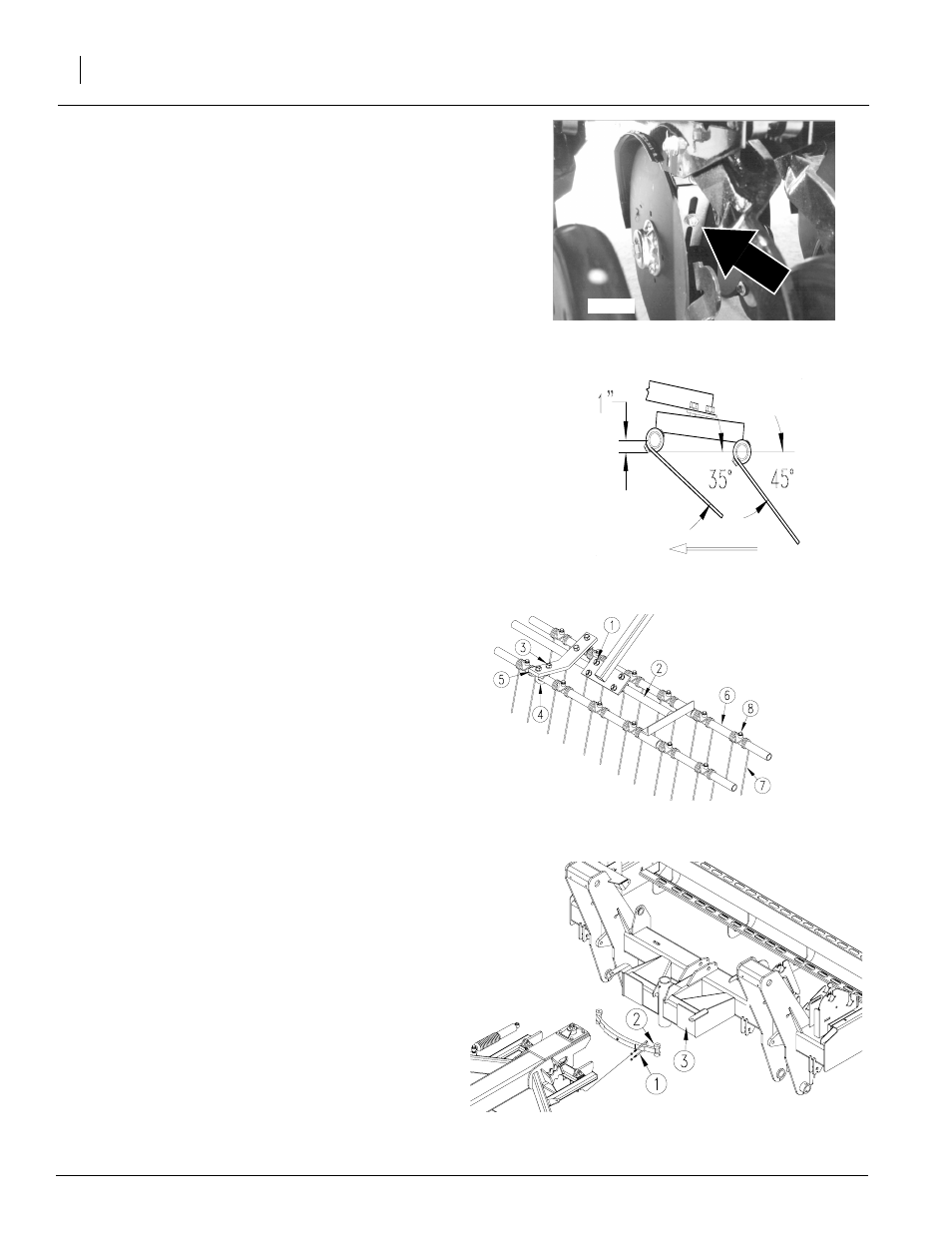

Disk Scraper Adjustment

Refer To Figure 22

To keep opener disks turning freely, dirt scrapers are

mounted between disks to clean as the disks rotate. As

field conditions vary, you may need to adjust the

scrapers.

To adjust, loosen 3/8-inch bolt and raise or lower scraper

as needed.

Harrow Adjustment

Refer to Figure 23

Figure 19 shows a successful harrow position for no-till

conditions. Because of different soil moisture, trash lev-

els and trash types, you may need to reposition the tube

frame or tines. Initially position the frame and tines as

shown in , then readjust as necessary.

Refer to Figure 24

To adjust the frame, loosen the four hex nuts (1) on the u-

bolts and rotate the frame tube (2) as necessary.

To adjust the tines, refer to . Loosen the four 1/2-inch hex

nuts (3) on the 1/2-inch u-bolts (4) on the support bar (5).

Rotate tine tubes (6) so the tines (7) are against the stop

bushings (8) and are angled back as necessary. Re-tight-

en hex nuts on u-bolts.

Leaf Spring Adjustment

Refer to Figure 25

A leaf spring is located just ahead of the vertical pivot.

Pre-emergence Marker Adjustment The spring is de-

signed to provide just enough force to keep the hitch

square and stable for turning at field ends and to add sta-

bility for drilling in rough field conditions. Proper leaf-

spring adjustment is important for smooth implement

operation.

To adjust properly, square tongue with transport frame

and adjust 3/8-inch u-bolts (1) on each side until leaf-

spring rollers (2) just make contact with roller pads (3) on

transport frame. Make sure both right and left sides are

adjusted properly.

16297

22619

Figure 22

Disk Scraper

16634

12667

Figure 23

Tine Angle for No-Till Drilling

Figure 24

Harrow Adjustment

Figure 25

Leaf Spring Adjustment