01 power source problems, Transmig 175i – Tweco 175i Transtig User Manual

Page 67

TRANSMIG 175i

Manual 0-5143

5-1 POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

SECTION 5:

POWER SOURCE PROBLEMS AND ROUTINE SERVICE

REQUIREMENTS

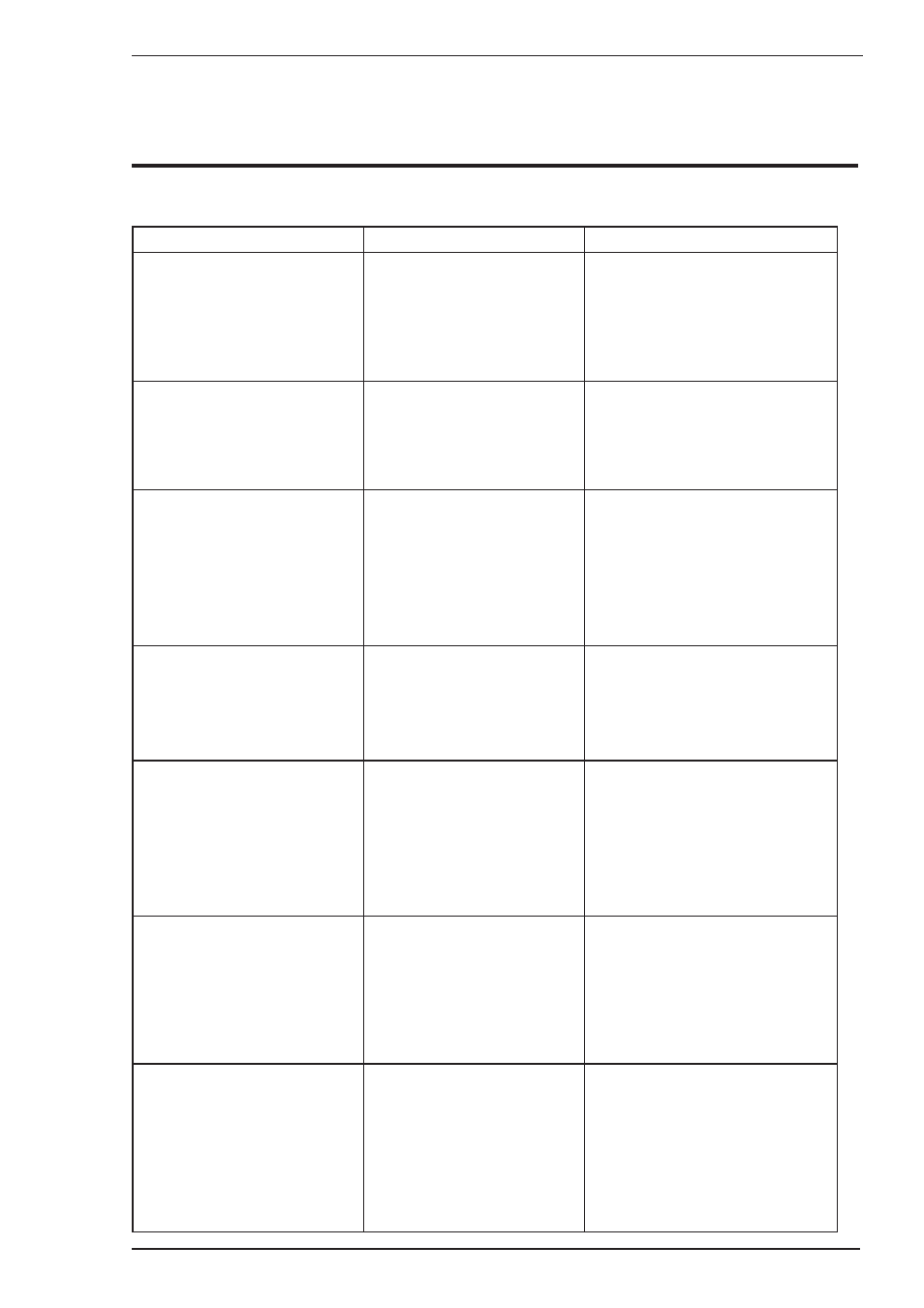

5.01 Power Source Problems

FAULT

CAUSE

REMEDY

1 Mains supply voltage is ON,

power indicator is illumi-

nated however unit will not

commence welding when

the torch trigger switch is

depressed.

A Power source is not in the

correct mode of operation.

A Set the power source to the cor-

rect mode of operation with the

process selection switch.

B Faulty torch trigger.

B Repair or replace torch trigger

switch/lead.

2 Fault Indicator is illumi-

nated and unit will not

commence welding when

the torch trigger switch is

depressed.

Duty cycle of power source

has been exceeded.

Leave the power source

switched ON and allow it to cool.

Note that fault indicator must

be extinguished prior to com-

mencement of welding.

3 Unit will not feed wire in

MIG mode.

A Electrode wire stuck in

conduit liner or contact tip

(burn-back jam).

A Check for clogged / kinked MIG

torch conduit liner or worn

contact tip. Replace faulty com-

ponents.

B Internal fault in power

source

B Have an Accredited CIGWELD

Service Provider investigate the

fault.

4 Welding wire continues to

feed when torch trigger is

released.

A Trigger mode selection

switch is in 4T latch mode.

A Change the trigger mode selec-

tion switch from 4T latch mode

to 2T normal mode.

B Torch trigger leads shorted. B Repair or replace torch trigger

switch/lead.

5 Welding arc cannot be

established in MIG mode.

A MIG torch polarity lead is

not connected into a weld-

ing output terminal.

A Connect the MIG torch polar-

ity lead to either the positive

welding output terminal or the

negative welding output terminal

as required.

B Poor or no work lead

contact.

B Clean work clamp area and en-

sure good electrical contact.

6 Inconsistent wire feed.

A Worn or dirty contact tip.

A Replace if necessary.

B Worn feed roll.

B Replace.

C Excessive brake tension on

wire reel hub.

C Reduce brake tension on spool

hub

D Worn, kinked or dirty con-

duit liner

D Clean or replace conduit liner

7 No gas flow in MIG mode.

A Gas hose is damaged.

A Replace or repair.

B Gas passage contains

impurities.

B Disconnect gas hose from

the rear of power source or

wirefeeder and blow out impuri-

ties.

C Gas regulator turned off.

C Turn on regulator.

D Empty gas cylinder.

D Replace gas cylinder.