Transmig 175i – Tweco 175i Transtig User Manual

Page 35

TRANSMIG 175i

Manual 0-5143

3-17

INSTALLATION, OPERATION AND SETUP

A-09586_AC

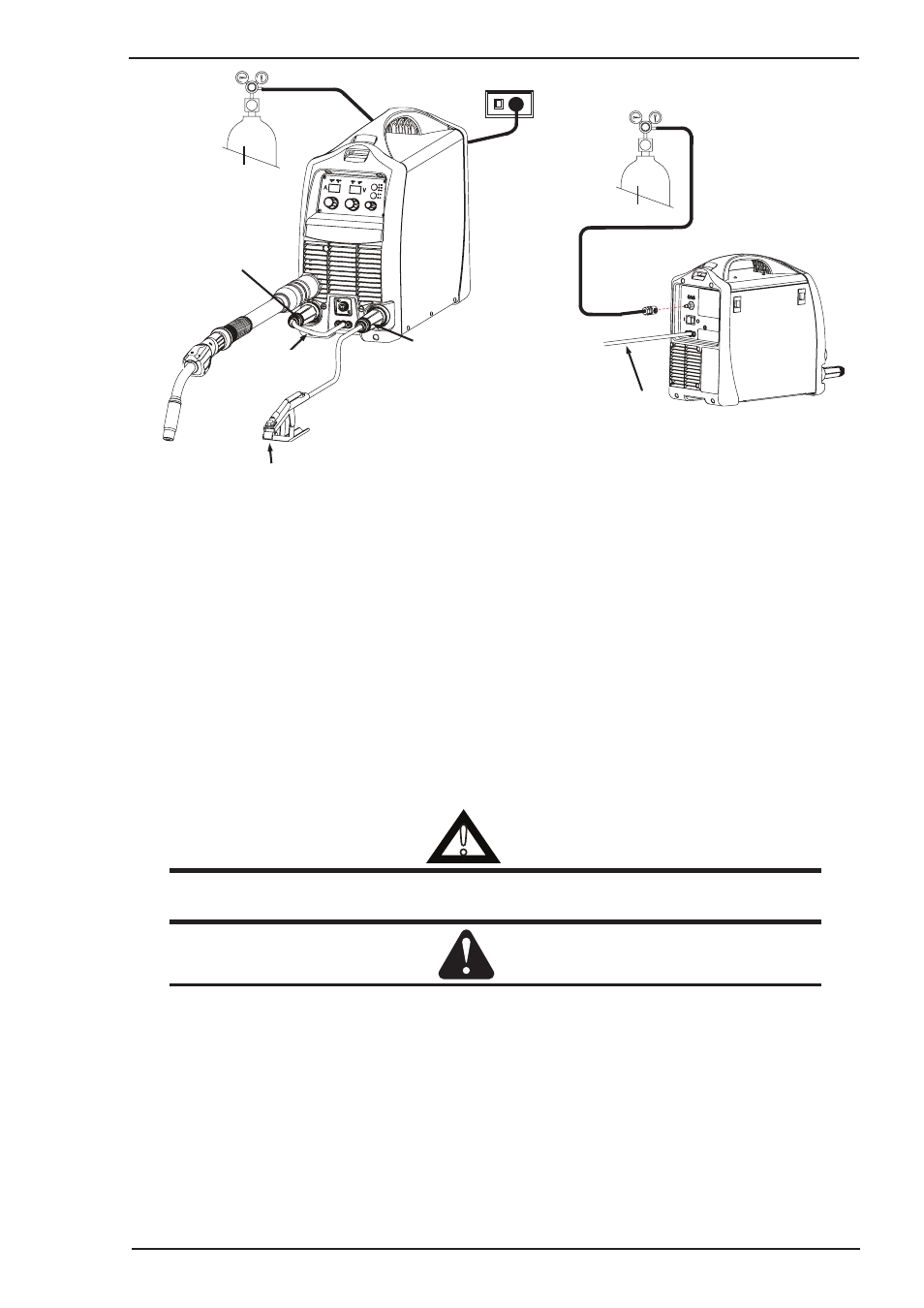

Shielding Gas Hose Fitted

with Quick

Connect

Supply Input Lead

Work Lead

Negative Welding

Terminal (-)

Positive Welding

Terminal (+)

MIG Torch

Polarity Lead

MIG Torch

Figure 3-15: Setup for Mig Welding with Gas Shielded Mig Wire

3.16 Setup for MIG (GMAW) Welding with Gasless Mig Wire

A. Select MIG mode with the process selection control (refer to Section 3.06.13 for further information).

B. Connect the Mig Torch polarity lead to the negative welding terminal (-). If in doubt, consult the electrode

wire manufacturer. Welding current flows from the power source via heavy duty bayonet type terminals.

It is essential, however, that the male plug is inserted and turned securely to achieve a sound electrical

connection.

C. Connect the work lead to the positive welding terminal (+). If in doubt, consult the electrode wire manufacturer.

Welding current flows from the power source via heavy duty bayonet type terminals. It is essential, however,

that the male plug is inserted and turned securely to achieve a sound electrical connection.

D. Refer to the Weld Guide located on the inside of the wirefeed compartment door for further information.

!

WARNING

Before connecting the work clamp to the work make sure the mains power supply is switched

off.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused

in the terminal.

Remove any packaging material prior to use. Do not block the air vents at the front or rear of the

Welding Power Source.