17 setup for tig (gtaw) welding, Transmig 175i – Tweco 175i Transtig User Manual

Page 36

TRANSMIG 175i

INSTALLATION, OPERATION AND SETUP

3-18

Manual 0-5143

A-09587_AB

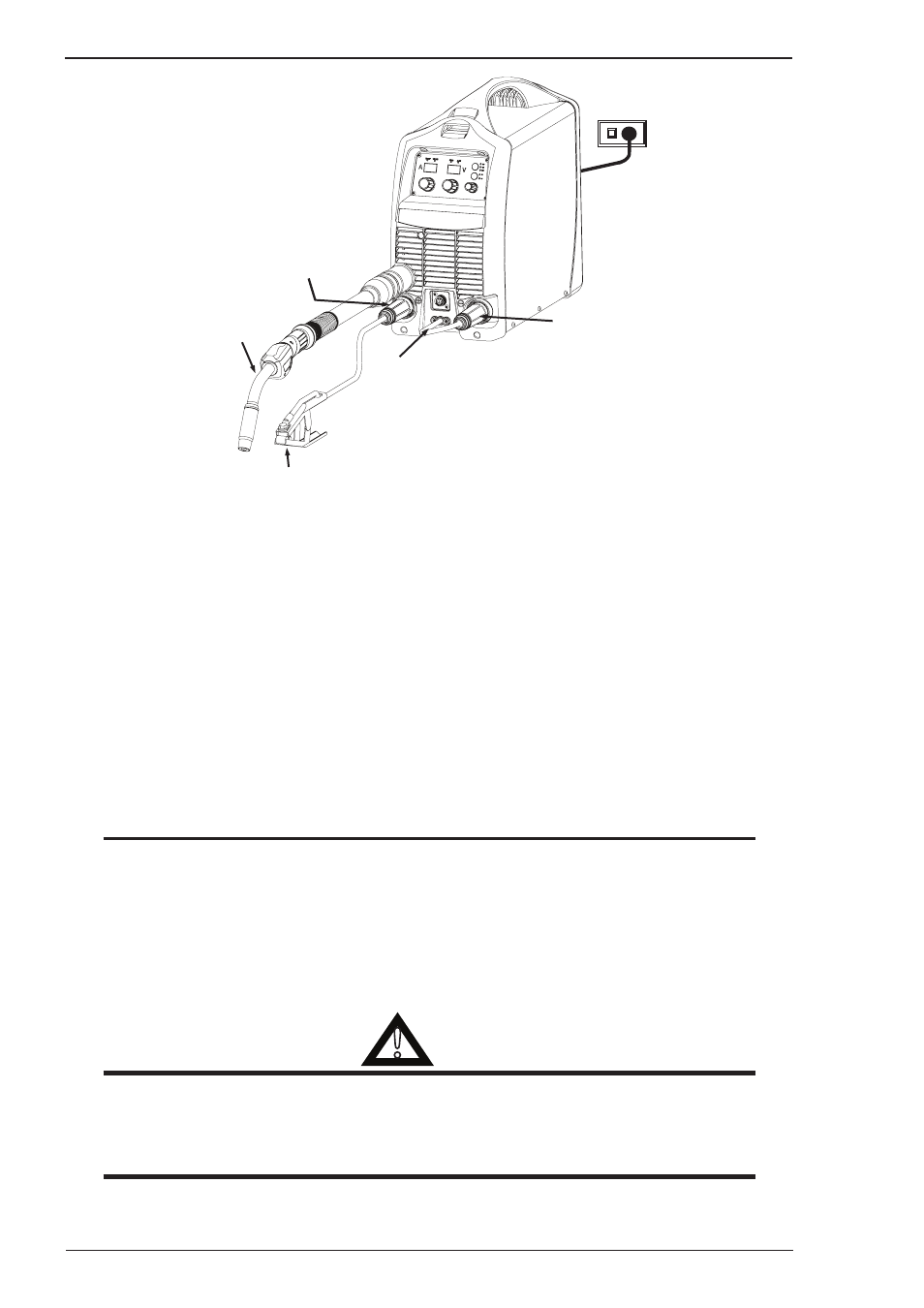

MIG Torch

Polarity Lead.

Negative Welding

Terminal (-)

Positive Welding

Terminal (+)

MIG Torch

Work Lead

Figure 3-16: Setup for Mig Welding with Gasless Mig Wire

3.17 Setup for TIG (GTAW) Welding

A. Select Lift TIG mode with the process selection control (refer to Section 3.06.13 for further information).

B. Connect the TIG Torch to the negative welding terminal (-). Welding current flows from the power source

via heavy duty bayonet type terminals. It is essential, however, that the male plug is inserted and turned

securely to achieve a sound electrical connection.

C. Connect the work lead to the positive welding terminal (+). Welding current flows from the Power Source

via heavy duty bayonet type terminals. It is essential, however, that the male plug is inserted and turned

securely to achieve a sound electrical connection.

D. Connect the TIG torch trigger switch via the 8 pin socket located on the front of the power source as shown

below. The TIG torch will require a trigger switch to operate in Lift TIG Mode.

NOTE

If the TIG torch has a remote TIG torch current control fitted then it will require to be connected to

the 8 pin socket. (Refer to section 3.06.9 Remote Control Socket for further information).

E. Fit the welding grade shielding gas regulator/flowmeter to the shielding gas cylinder (refer to Section 3.14)

then connect the shielding gas hose from the TIG torch to the regulator/flowmeter outlet. Note that the TIG

torch shielding gas hose is connected directly to the regulator/flowmeter. The power source is not fitted

with a shielding gas solenoid to control the gas flow in TIG mode therefore the TIG torch will require a gas

valve.

!

WARNING

Before connecting the work clamp to the work and inserting the electrode in the TIG Torch make

sure the mains power supply is switched off.

Secure the welding grade shielding gas cylinder in an upright position by chaining it to a stationary

support to prevent falling or tipping.