Transmig 175i – Tweco 175i Transtig User Manual

Page 24

TRANSMIG 175i

INSTALLATION, OPERATION AND SETUP

3-6

Manual 0-5143

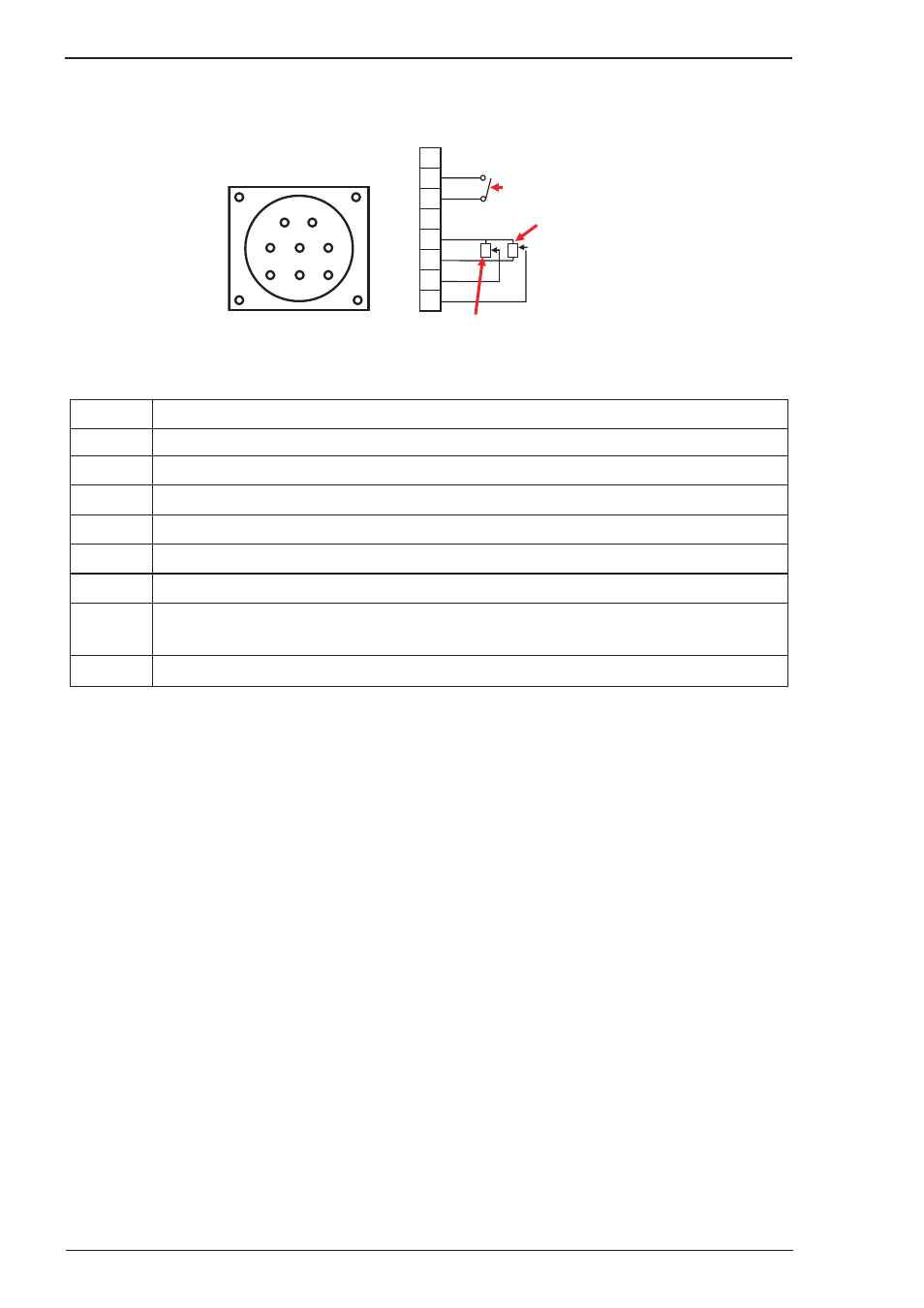

9. Remote Control Socket

The 8 pin Remote Control Socket is used to connect remote control devices to the welding power source.

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

2

1

8

7

6

3

4

5

Trigger Switch

Remote Wirespeed in GMAW mode

Remote Amps in GTAW mode

Remote Volts in

GMAW Mode

1

2

3

4

5

6

7

8

W

V

A-09594

Figure 3-4: Remote Control Socket

Socket Pin

Function

1

Not connected

2

Trigger Switch Input

3

Trigger Switch Input

4

Not connected

5

5k ohm (maximum) connection to 5k ohm remote control potentiometer.

6

Zero ohm (minimum) connection to 5k ohm remote control potentiometer.

7

Wiper arm connection to 5k ohm remote control Wirespeed GMAW (MIG) mode potentiometer.

Wiper arm connection to 5k ohm remote control Amps GTAW (TIG) mode potentiometer.

8

Wiper arm connection to 5k ohm remote control Volts GMAW (MIG) mode potentiometer.

Table 3-1

Note that the remote local switch (item 18) located in the wirefeed compartment should be set to remote

for the amperage/voltage controls to be operative.

10. Multifunction Control - Voltage, Down Slope & Arc Force

The multifunction control knob is used to adjust three main parameters depending on the welding mode

selected.

When GMAW/FCAW (MIG) Mode is Selected

In this mode the control knob is used to adjust the output voltage of the unit. The welding voltage is

increased by turning the knob clockwise or decreased by turning the knob anti-clockwise. The optimum

voltage level required will dependent on the type of welding application. The setup chart on the inside

of the wire feed compartment door provides a brief summary of the required output settings for a basic

range of MIG welding applications.

When MMAW (Stick) Mode is Selected

In this mode the multifunction control knob is used to adjust arc force. Arc force control provides an

adjustable amount of welding force (or “dig”) control. This feature can be particularly beneficial in

providing the operator the ability to compensate for variability in joint fit-up in certain situations with

particular electrodes. In general increasing the arc force control toward ‘10’ (maximum arc force) allows

greater penetration control to be achieved. Arc force is increased by turning the control knob clockwise

or decreased by turning the knob anti-clockwise