02 mig (gmaw/fcaw) welding troubleshooting, Transmig 175i – Tweco 175i Transtig User Manual

Page 45

TRANSMIG 175i

Manual 0-5143

4-7

BASIC WELDING GUIDE

4.02 MIG (GMAW/FCAW) Welding Troubleshooting

Solving Problems Beyond the Welding Terminals

The general approach to fix Gas Metal Arc Welding (GMAW) problems is to start at the wire spool then

work through to the MIG torch. There are two main areas where problems occur with GMAW, Porosity and

Inconsistent wire feed

Solving Problems Beyond the Welding Terminals - Porosity

When there is a gas problem the result is usually porosity within the weld metal. Porosity always stems from

some contaminant within the molten weld pool which is in the process of escaping during solidification of

the molten metal. Contaminants range from no gas around the welding arc to dirt on the work piece surface.

Porosity can be reduced by checking the following points.

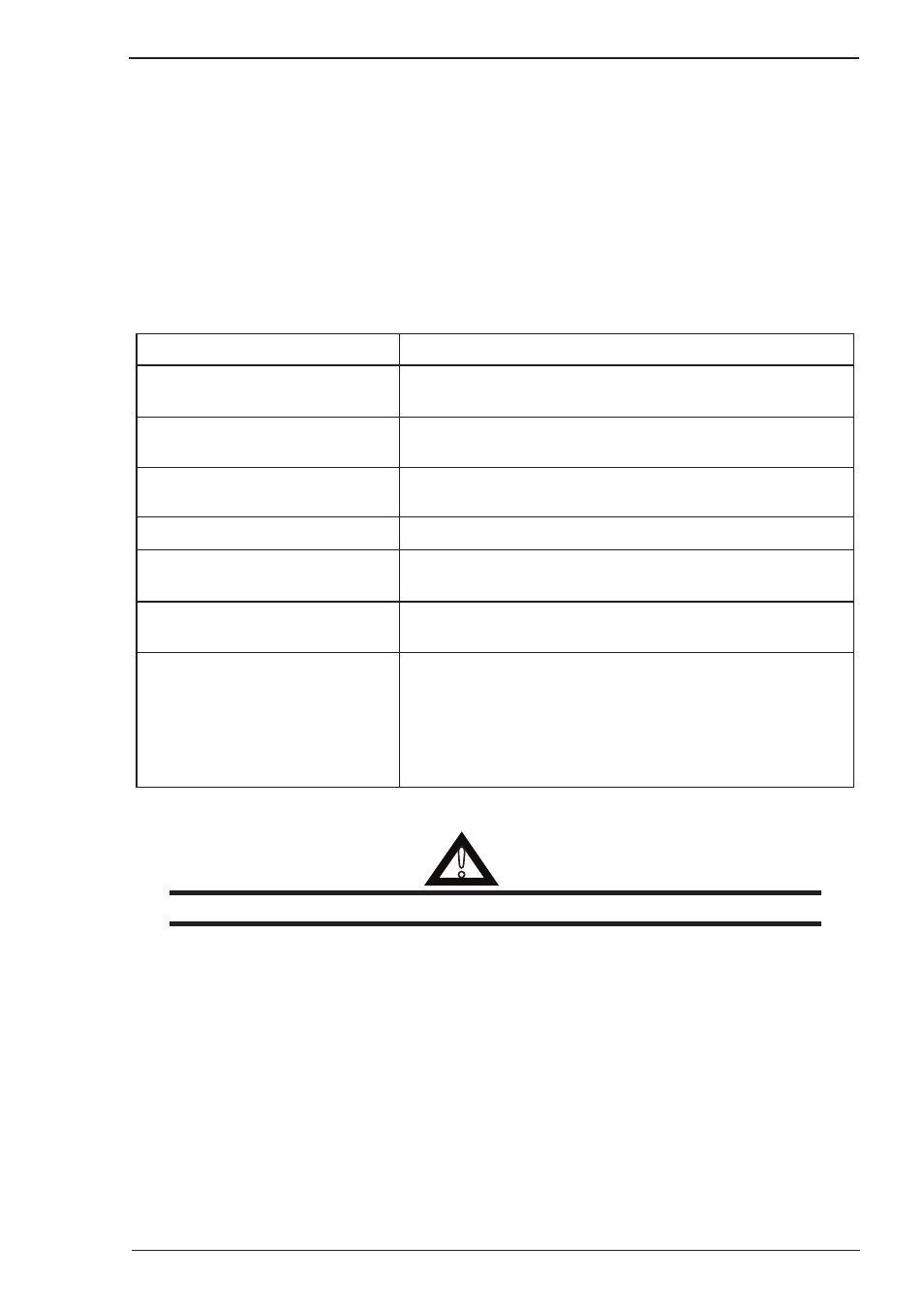

FAULT

CAUSE

1Shielding gas cylinder contents

and flow meter.

Ensure that the shielding gas cylinder is not empty and the

flow meter is correctly adjusted to 15 litres per minute.

2Gas leaks.

Check for gas leaks between the regulator/cylinder connec-

tion and in the gas hose to the Power Source.

3Internal gas hose in the Power

Source.

Ensure the hose from the solenoid valve to the torch adaptor

has not fractured and that it is connected to the torch adaptor.

4Welding in a windy environment.

Shield the weld area from the wind or increase the gas flow.

5Welding dirty, oily, painted,

oxidised or greasy plate.

Clean contaminates off the work piece.

6Distance between the MIG torch

nozzle and the work piece.

Keep the distance between the MIG torch nozzle and the work

piece to a minimum. Refer to section 2.03

7Maintain the MIG torch in good

working order.

AEnsure that the gas holes are not blocked and gas is exiting

out of the torch nozzle.

BDo not restrict gas flow by allowing spatter to build up inside

the torch nozzle.

CCheck that the MIG torch O-rings are not damaged.

Table 4-2: Solving Problems beyond the Welding Terminals-Porosity

!

WARNING

Disengage the feed roll when testing for gas flow by ear.