10 specifications, Transmig 175i – Tweco 175i Transtig User Manual

Page 17

TRANSMIG 175i

Manual 0-5143

2-5

INTRODUCTION

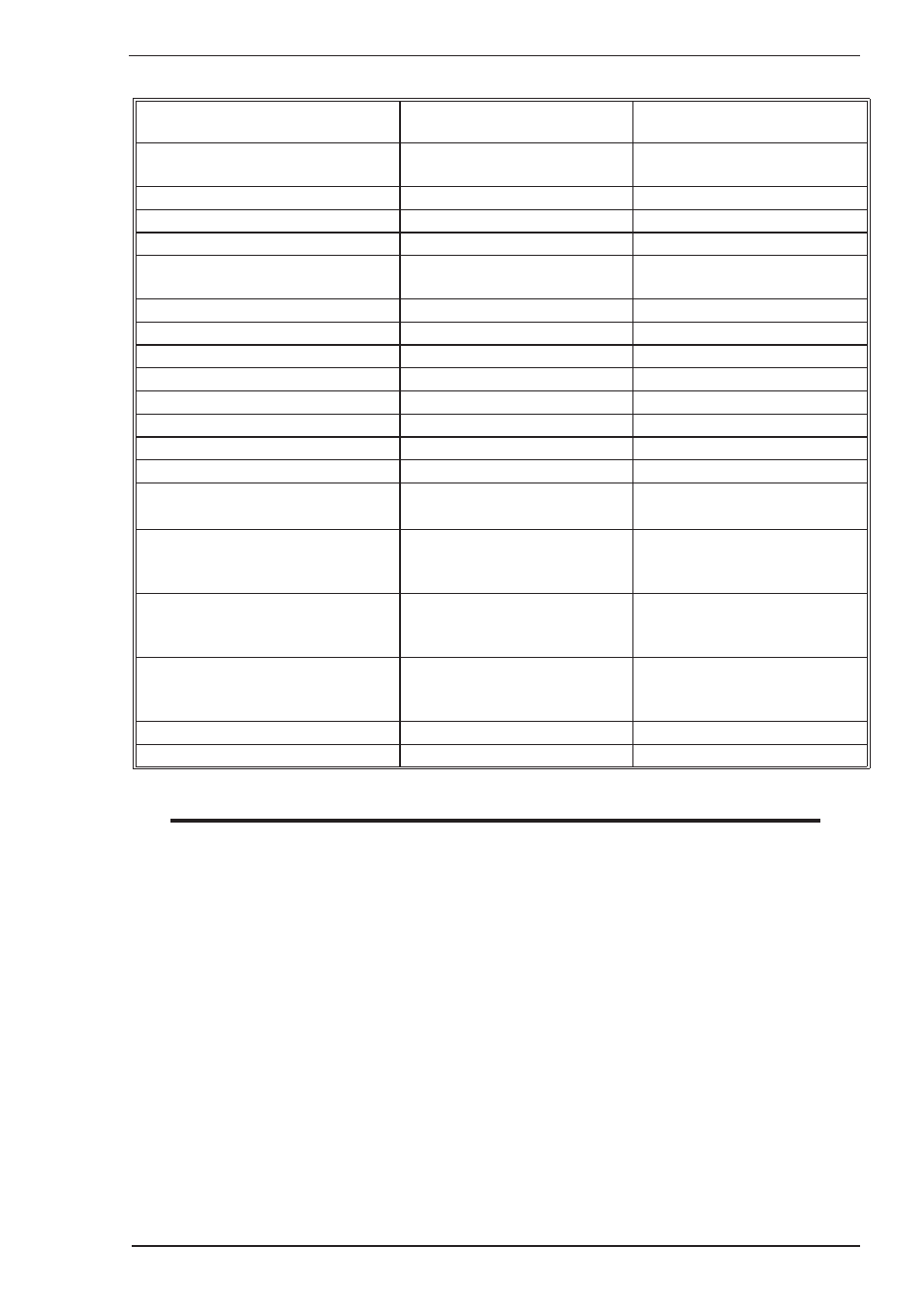

2.10 Specifications

Description

TRANSMIG 175i

(South Pacific Version)

TRANSMIG 175i

(Asia Version)

Plant Part Number

Power Source (Packed) Part Number

W1005175

W1005176

W1005175M

W1005176M

Power Source Dimensions

H410mm x W210mm x D450mm H410mm x W210mm x D450mm

Power Source Mass

14.6kg

14.6kg

Cooling

Fan Cooled

Fan Cooled

Welder Type

Multi Process Inverter Power

Source

Multi Process Inverter Power

Source

Australian Standard

AS60974-1 / IEC60974-1

AS60974-1 / IEC60974-1

Number of Phases

Single Phase

Single Phase

Nominal Supply Voltage

240 VAC ± 15%

240 VAC ± 15%

Nominal Supply Frequency

50 / 60Hz

50 / 60Hz

Welding Current Range (MIG mode)

10 – 175A

10 – 175A

Factory Fitted Supply Plug Rating

15Amps

Asian Style Input Plug

1

Effective Input Current (I

1eff

)

15Amps

15Amps

Maximum Input Current (I

1max

)

35.5Amps

35.5Amps

Minimum Single Phase Generator

Recommendation (refer Note 3)

9kVA

[9kVA @ 0.8 Power Factor]

9kVA

[9kVA @ 0.8 Power Factor]

MIG (GMAW)

Welding Output, 40º C, 10 min.

175A @ 25%, 22.8V

113A @ 60%, 19.7V

88A @ 100%, 18.4V

175A @ 25%, 22.8V

113A @ 60%, 19.7V

88A @ 100%, 18.4V

STICK (MMAW)

Welding Output, 40º C, 10 min.

175A @ 20%, 27.0V

101A @ 60%, 24.0V

78A @ 100%, 23.1V

175A @ 20%, 27.0V

101A @ 60%, 24.0V

78A @ 100%, 23.1V

TIG (GTAW)

Welding Output, 40º C, 10 min.

175A @ 25%, 17.0V

113A @ 60%, 14.5V

88A @ 100%, 13.5V

175A @ 25%, 17.0V

113A @ 60%, 14.5V

88A @ 100%, 13.5V

Open Circuit Voltage (VRD active)

65V

65V

Protection Class

IP23S

IP23S

Table 2-1: Transmig 175i Specification

NOTE

Note 1:

The Effective Input Current should be used for the determination of cable size & supply

requirements.

Note 2: Motor start fuses or thermal circuit breakers are recommended for this application.

Check local requirements for your situation in this regard.

Note 3: Minimum Generator Recommendation at the Maximum Output Duty Cycle.

Due to large variations in performance and specifications of different brands and types of genera-

tors, Cigweld cannot guarantee full welding output power or duty cycle on every brand or type of

generator.

Some small generators incorporate low cost circuit breakers on their outputs. These circuit break-

ers usually will have a small reset button, and will trip much faster than a switchboard type circuit

breaker. This may result in not being able to achieve full output or duty cycle from the power source

/ generator combination. For this reason we recommend a generator that incorporates switchboard

type circuit breakers.

In some circumstances, long welds at high welding current may trip the circuit breaker on the

generator.

Cigweld recommends that when selecting a generator, that the particular power source / generator

combination be adequately trialled to ensure the combination performs to the users expectations.