Transmig 175i – Tweco 175i Transtig User Manual

Page 42

TRANSMIG 175i

BASIC WELDING GUIDE

4-4

Manual 0-5143

Secondary Adjustable Variables

These variables cause changes in primary adjustable variables which in turn cause the desired change in the

bead formation. They are:

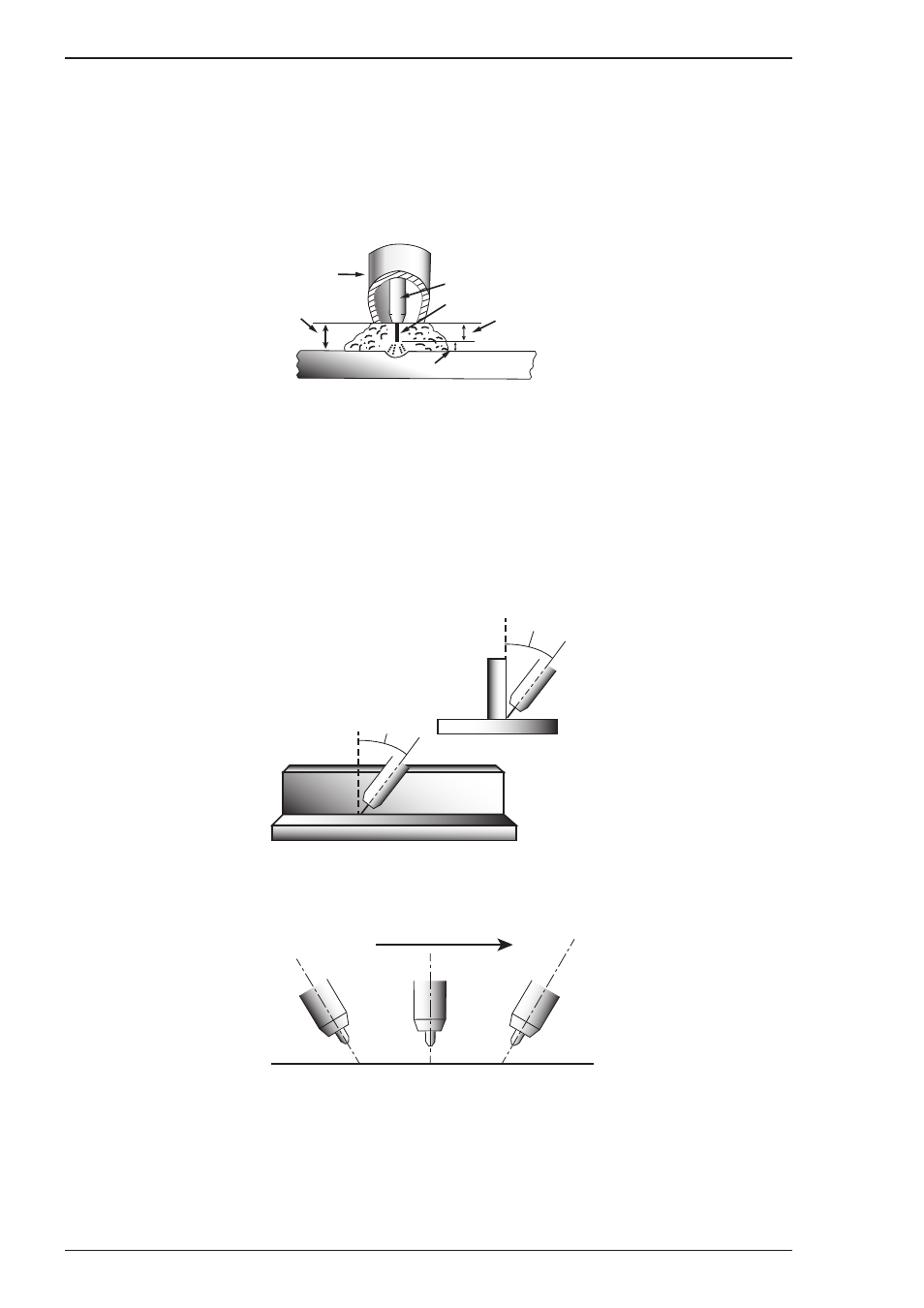

1. Stick-out (distance between the end of the contact tube (tip) and the end of the electrode wire). Maintain

at about 10mm stick-out

2. Wire Feed Speed. Increase in wire feed speed increases weld current, Decrease in wire feed speed

decreases weld current.

Art # A-08997_AD

Gas Nozzle

Electrode Wire

Average Arc Length

Electrode Stick-Out

Tip to

Work Distance

Actual Stick-out

Contact Tip (Tube)

Figure 4-8

3. Nozzle Angle. This refers to the position of the welding gun in relation to the joint. The transverse angle

is usually one half the included angle between plates forming the joint. The longitudinal angle is the

angle between the centre line of the welding gun and a line perpendicular to the axis of the weld. The

longitudinal angle is generally called the Nozzle Angle and can be either trailing (pulling) or leading

(pushing). Whether the operator is left handed or right handed has to be considered to realize the

effects of each angle in relation to the direction of travel.

Transverse and Longitudinal

Nozzle Axes

Art # A-08998_AB

Longitudinal

Angle

Axis of Weld

Transverse

Angle

Figure 4-9

Art # A-08999_AC

Nozzle Angle, Right Handed Operator

Direction of Gun Travel

Leading or “Pushing”

Angle

(Forward Pointing)

Trailing or “Pulling”

Angle

(Backward Pointing)

90°

Figure 4-10