13 wire reel brake, 14 shielding gas regulator operating instructions, Transmig 175i – Tweco 175i Transtig User Manual

Page 31

TRANSMIG 175i

Manual 0-5143

3-13

INSTALLATION, OPERATION AND SETUP

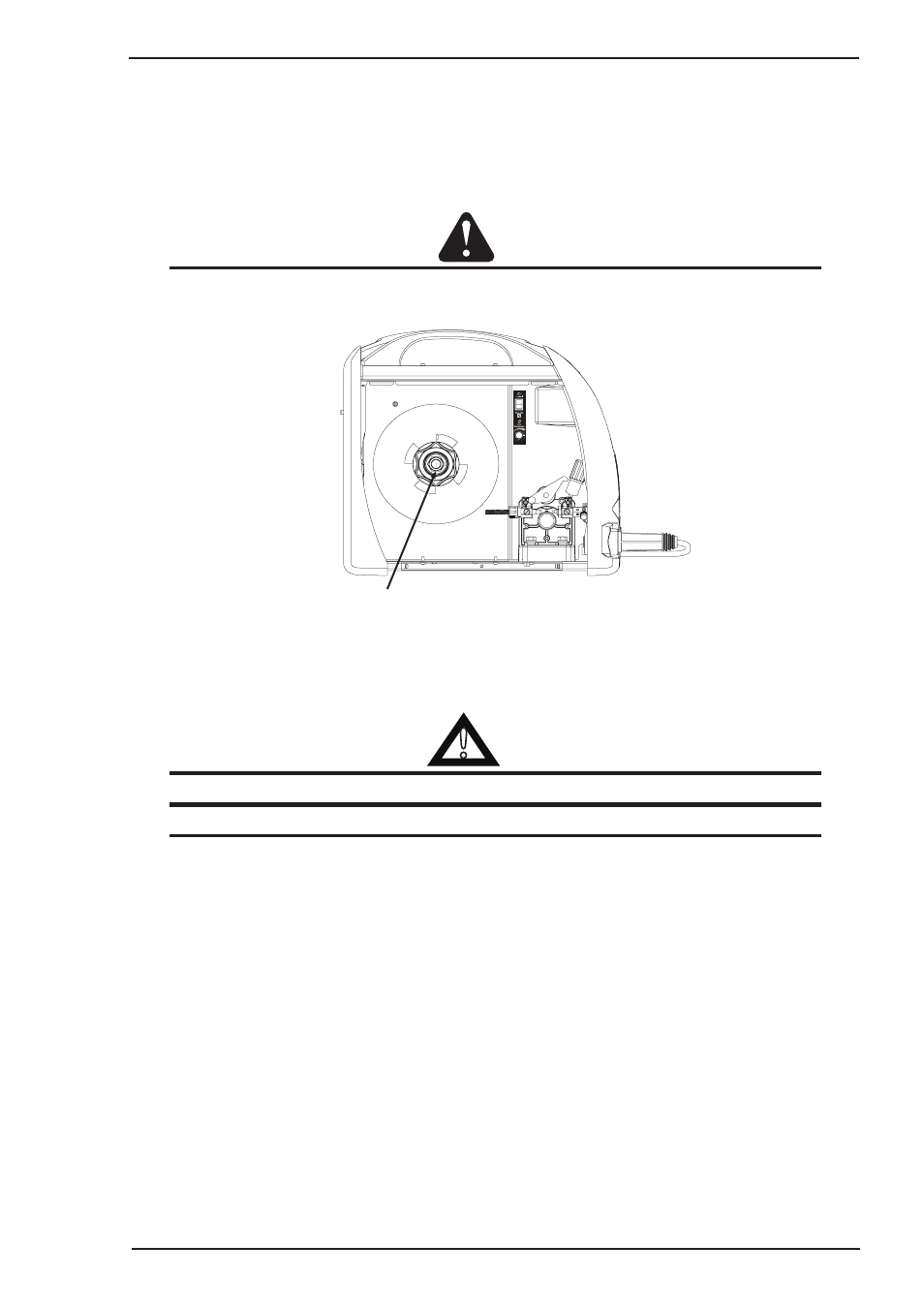

3.13 Wire Reel Brake

The wire reel hub incorporates a friction brake which is adjusted during manufacture for optimum breaking.

If it is considered necessary, adjustment can be made by turning the large nut inside the open end of the

hub clockwise to tighten the brake. Correct adjustment will result in the wire reel circumference continuing

no further than 10-20mm after release of the trigger. The electrode wire should be slack without becoming

dislodged from wire spool.

CAUTION

Overtension of brake will cause rapid wear of mechanical WIREFEED parts, overheating of electrical

componentry and possibly an increased incidence of electrode wire Burnback into contact tip.

Wire Reel Brake Adjustment Nut

A-09585

Figure 3-12: Wire Reel Brake

3.14 Shielding Gas Regulator Operating Instructions

!

WARNING

This equipment is designed for use with welding grade (Inert) shielding gases only.

NOTE

Shielding Gas Regulator not included in the Transmig 175i (Asia Version) Plant Part No

W1005175M.

Shielding Gas Regulator Safety

This regulator is designed to reduce and control high pressure gas from a cylinder or pipeline to the working

pressure required for the equipment using it.

If the equipment is improperly used, hazardous conditions are created that may cause accidents. It is the

users responsibility to prevent such conditions. Before handing or using the equipment, understand and

comply at all times with the safe practices prescribed in this instruction.

SPECIFIC PROCEDURES for the use of regulators are listed below.

1. NEVER subject the regulator to inlet pressure greater than its rated inlet pressure.

2. NEVER pressurize a regulator that has loose or damaged parts or is in a questionable condition. NEVER

loosen a connection or attempt to remove any part of a regulator until the gas pressure has been

relieved. Under pressure, gas can dangerously propel a loose part.

3. DO NOT remove the regulator from a cylinder without first closing the cylinder valve and releasing gas

in the regulator high and low pressure chambers.