Ultra-cut 100 xt, Control cable, Arc voltage connections – Tweco 100 Ultra-Cut Plasma Cutting System with Automated Gas Control User Manual

Page 68: Ohmic” or shield (cup) cable, Ferrite cores

ULTRA-CUT 100 XT

3-��

INSTALLATION

Manual 0-5303

Control Cable.

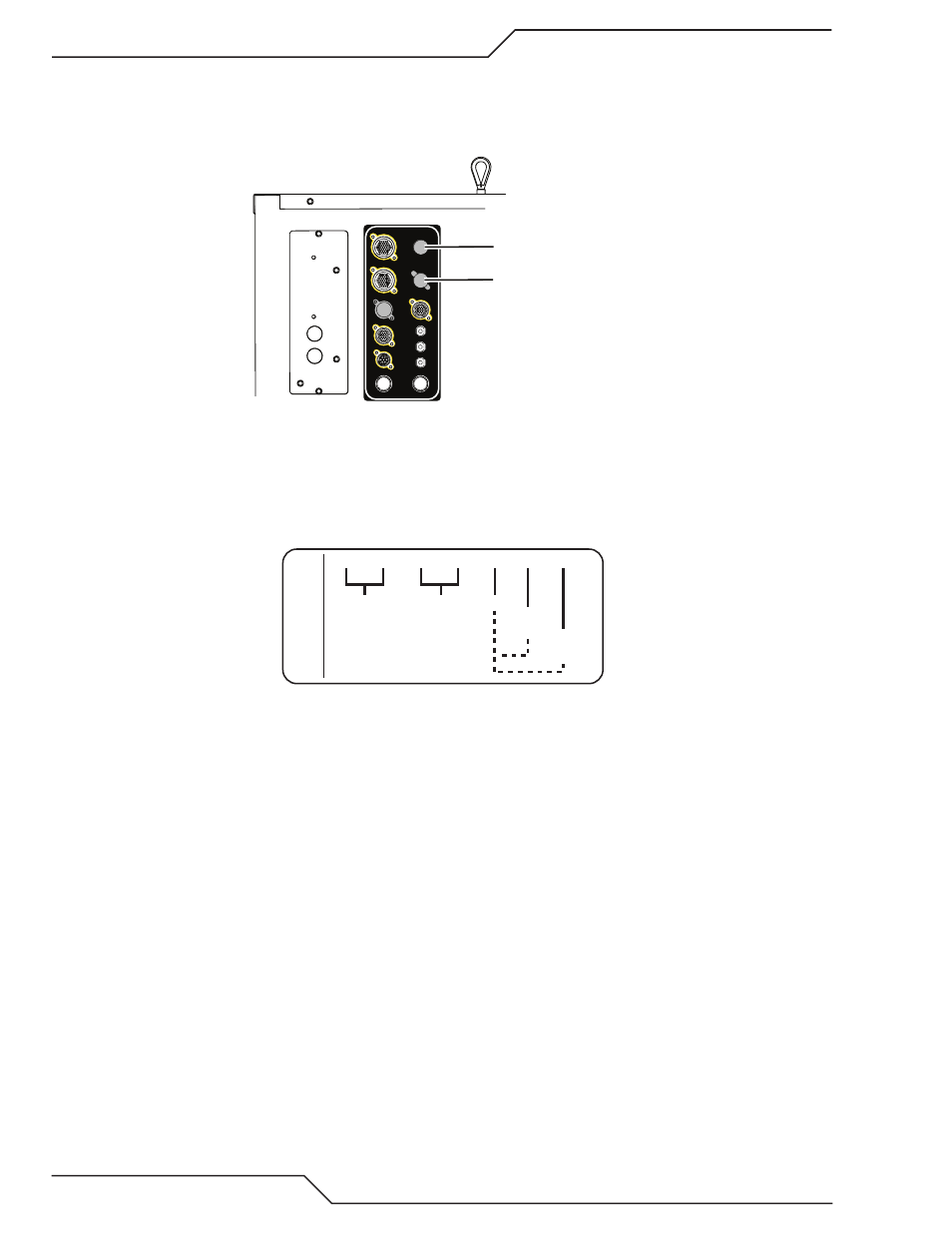

The iHC board can be supplied with a wire harness and connector (shown in previous image), to be installed in

the rear panel hole labeled “Height Control” . The connector mates with a cable from the iHC. For other height

control V-D boards a strain relief can be installed in this hole for those cables. Refer to Appendix for wiring diagram.

USER INPUT

HEIGHT CONTROL

F1 - 8A SB 230 VAC

F2 - 8A SB 230 VAC

CB4 - 5A 120 VAC

CB3 - 5A 24 VAC

CB2 - 5A 120 VAC

J55 - GCM

J15 - CNC

J59 - RAS

J70 - HE

J54 - TSC /COMM

Ohmic clip cable port

V-D Board connection

Art # A-12080

Arc Voltage Connections.

The XT plasma supplies provide a terminal strip, TB�, on the right side ahead of the CCM module for connections

to Arc V- (Torch); Tip V (Pilot); Arc V + (Work). If the V-D board requires separate power, 2� VAC and 120 VAC is

available on the terminal strip TB�. Refer to the wiring diagram in the Appendix for more information.

24 VAC

@ 1A

TB4

1

2

3

4

5

6

7

120 VAC

@ 100 ma.

Work

Tip Volts

(Pilot)

Arc Volts

(Torch)

Art # A-11954

“Ohmic” or Shield (cup) cable.

Some height controls including the iHC find the plate using an electrical or resistance measurement, thus “ohmic”,

contact between the conductive end of the torch and the metal or “plate” being cut. A wire, usually a single highly

flexible wire that withstands the reflective heat from the arc, is connected between the V-D board and the torch shield

cup. The XT torch includes a metal spring clip which slips into a groove in the shield cup allowing easy removal for

parts change. The Ohmic wire can be connected to this clip with a ¼” female push-on terminal.

Significant amounts of high frequency (HF) energy causing electromagnetic interference (EMI) can be conducted

along this wire due to it’s close coupling to the torch. This is the reason for mounting the V-D board away from

the CCM and close to the rear panel where the Ohmic wire does not need to pass near other sensitive electronics.

It is especially recommended that the Ohmic wire not be routed near the CCM module or along the torch leads.

Refer to Appendix for wiring diagram.

Ferrite cores.

It is recommended that the Ohmic Sensing wire be wrapped through a ferrite core with several turns, at least 3 but

more is better, to reduce the energy conducted to the V-D board and into the plasma supply. The ferrite core should

be located on the wire where it enters the plasma supply. A second ferrite core added several feet (couple of meters)

from the torch will further reduce the conducted EMI that may couple to other cable/wires and cause interference.

Refer to Appendix for wiring diagram.