Ultra-cut 100 xt – Tweco 100 Ultra-Cut Plasma Cutting System with Automated Gas Control User Manual

Page 199

ULTRA-CUT 100 XT

Manual 0-5303

APPENDIX

A-75

Reasons for �0� faults (Coolant not flowing):

• In new installation, coolant has not circulated all the way through the leads. Add more coolant if neces-

sary and recycle the power to restart the pump and � minute timer.

• Coolant supply & return leads are reversed, check valve in torch coolant return prevents reverse flow.

• Torch parts removed or are wrong style so torch check valve shuts off flow.

• Torch coolant tube damaged or the tube extension (if required) missing.

• No power to pump motor.

• Pump/motor failure.

• Bypass valve defective or adjusted incorrectly.

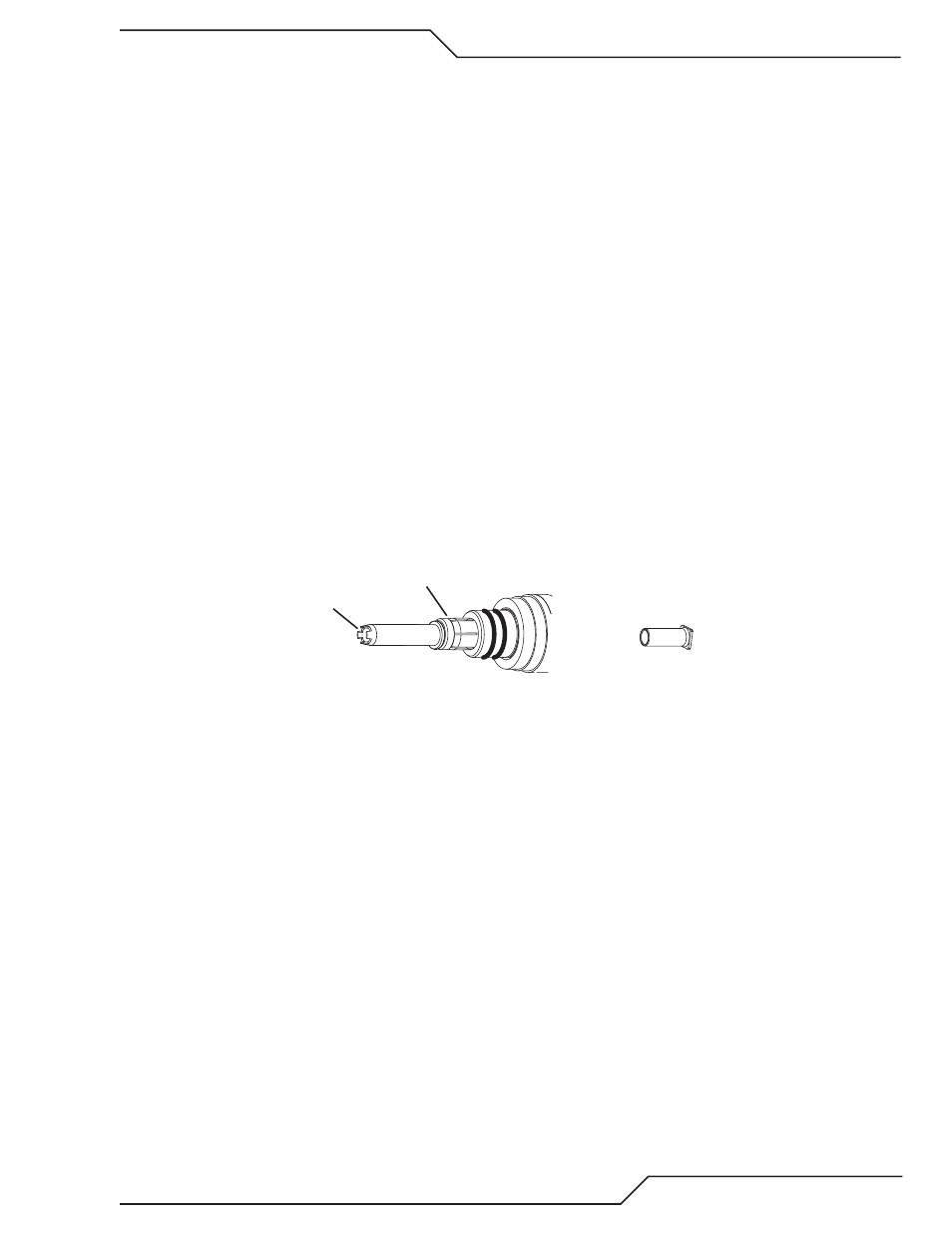

Damaged Coolant Tube

Coolant tube includes a check valve at its upper end. When cartridge with consumables is not installed the

spring loaded coolant tube is fully extended closing the check valve preventing coolant from leaking out.

When consumables are in place they push the tube inward, opening the check valve, allowing coolant to flow.

The coolant tube has fingers on the end to contact the inside of the electrode and allow coolant to flow through

the openings between the fingers.

The fingers can be bent over or broken if reasonable care is not taken when the cartridge is not in place. If the

fingers are bent or broken it shortens the tube so the consumables may not push the tube in enough to open

the check valve resulting in no coolant flow. The coolant tube assembly may be replaced separately from the

torch head.

Some consumables use an extension on the coolant tube. A missing extension will not allow the check valve

to open.

Art # 12312

Coolant Tube Extension

Fingers

Internal Check Valve

No Power to the Pump Motor

The pump motor is powered by 230 VAC controlled by the MC3 control relay. During the � minutes after turning

on power, before the �0� fault code is displayed, measure for 230 VAC at the motor connector J1� pin 1 to pin 3.

a. If the pump motor is not getting 230 VAC, measure for 24 VAC on the coil of MC3. If present and the relay

contacts aren’t closed the relay is defective. Note, the coil is rectified so you won’t measure continuity of

even a good coil.

b. If 24 VAC is not on the MC3 coil check for D27 on the relay board being ON. If it’s on the Relay board should

be providing the 24 VAC so if it’s not the Relay board may be defective. Measure for 24 VAC at J9-6 to J9-12

on the Relay board. If 24 VAC is present and D27 is on, the Relay board or the wire harness is defective.

c. If D27 is not on, measure on the CCM I/O board between TP3 and the common at TP1. It should be low,

near zero volts. If not the CCM is probably defective. Jumper TP3 (I/O board) to TP1. If the pump comes

on now replace the CCM.