02 system layout 100 - 200 amp – Tweco 400 Ultra-Cut XT Plasma Cutting System User Manual

Page 30

ULTRA-CUT 100 XT/200 XT/300 XT/400 XT

3-2

INSTALLATION

Manual 0-5297

Gas Supply

The customer must supply all gases and pressure regulators. Gases must be of high quality. Pressure regulators

must be double-stage and installed as close as possible to the gas console. Contaminated gas can cause one or more

of the following problems:

• Reduced cutting speed

• Poor cut quality

• Poor cutting precision

• Reduced consumables life.

• Oil or grease contamination from compressed or bottled air can cause fires in conjunction with oxygen.

Cooling System Requirements

Coolant must be added to the system on installation. The amount required varies with torch leads length.

Victor Thermal Dynamics recommends the use of its coolants 7-3580 and 7-3581 (for low temperatures).

Coolant Capabilities

Cat. Number and Mixture

Mixture

Protects To

7-3580 ‘Extra-Cool™’

25 / 75

10° F / -12° C

7-3581 ‘Ultra-Cool™’

50 / 50

-27° F / -33° C

7-3582 ‘Extreme Cool™’

Concentrate*

-76° F / -60° C

* For mixing with D-I Cool™ 7-3583

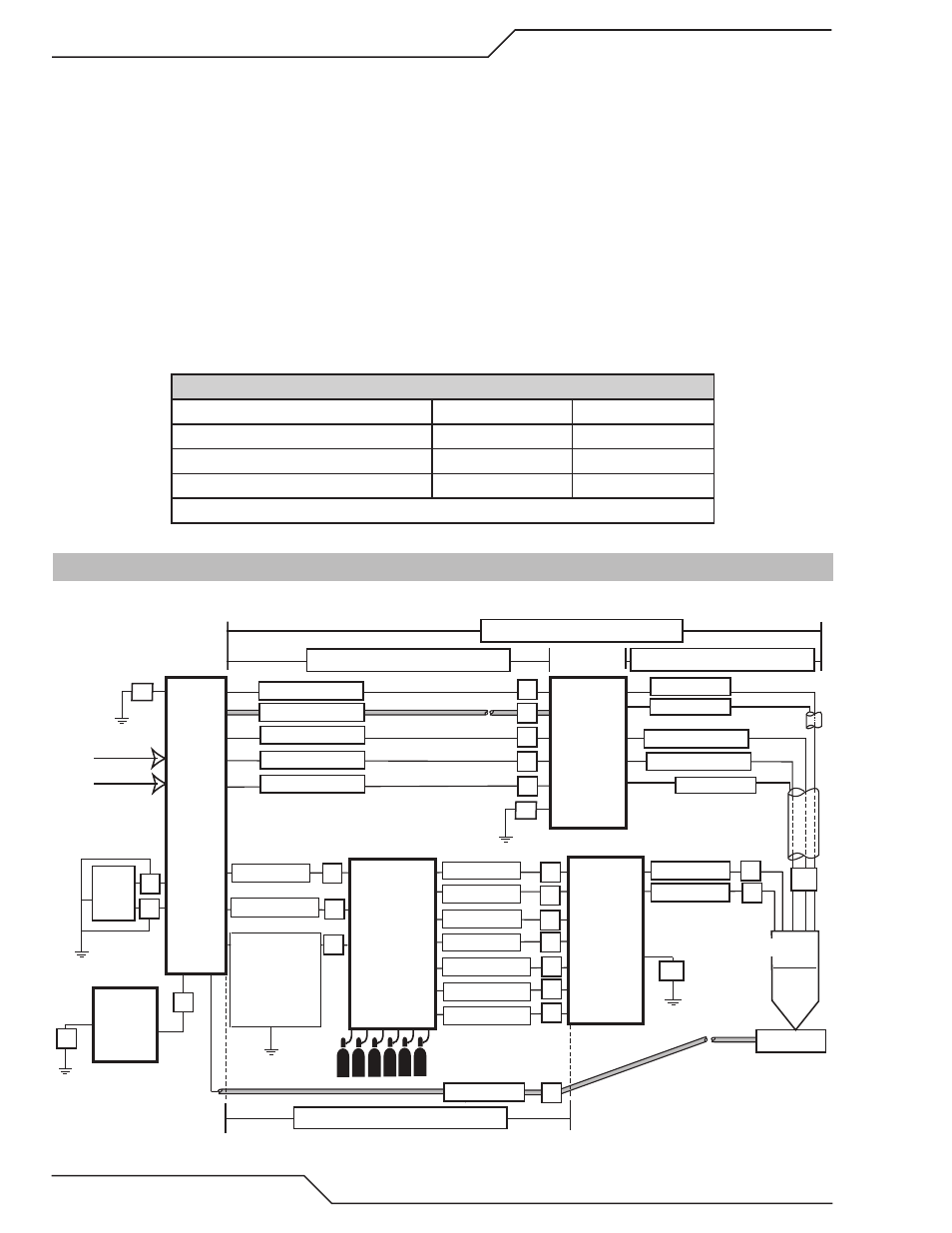

3.02 System Layout 100 - 200 Amp

Refer to section 3.08 and 3.10 for ground connections and ground cables.

Primary power

Work

CNC

Remote

Arc

Starter

Art # A-11995

Torch

Coolant Supply

Coolant Return

Control Cable

Pilot Return

Coolant Supply

Coolant Return

Plasma Gas

Shield Gas

Work Cable

DMC-3000

Gas

Console

Ultra-Cut

Power

Supply

DPC-3000

Gas

Control

Positioning Tube

Plasma Gas

Marking

Shield

Shield Gas

Negative

Pilot Return

Control Cable

100’ / 30.5 m Maximum Length

Shield

H

Q

R

U

S

A

B

C

D

E

P

K

L

O

I

J

G

175’ / 53.3 m Maximum Length

Preflow

Fiber Optic

L

Water Shield

T

125’ / 38.1 m Maximum Length

175’ / 53.3 m Maximum Length

Fiber Optic

Control Cable

F

Touch

Screen

Controller

V

W

F1

F1

F

F

Ground Cable

to PS Only

When DMC

Mounted On

Top Of PS

-If not - Earth-