Valve sizing and selection cont – Powers 596 Series Flowrite II Heavy Duty Control Valves - Type MI Mixing User Manual

Page 4

4

Cavitation, Flashing and Choked Flow:

Limitations on Valve Pressure Drop

A concern in high temperature water systems is the potential

for cavitation, which is caused by the downstream pressure

being lower than that of the vapor pressure of the fluid. This

basically causes the water to "boil" and can result in reduced

flow/capacity, excessive noise, vibration, wear and should be

avoided if possible. If the pressure downstream of the area

restriction rises rapidly above the vapor pressure, the vapor

bubbles will collapse violently (implode). The bubble collapse is

an affirmation of cavitation. Use the following equation below

to estimate the maximum allowable pressure drop across the

valve.

Flashing is a phenomenon where the flowing high temperature

water inlet experiences a significant pressure drop, with the

outlet pressure below the vapor pressure of the water (as in

cavitation) and is converted to a vapor within the control region

of the valve.

This can also produce a choked flow condition where the rapid-

ly expanding vapor prohibits any increase in flow, even though

P1 (inlet) pressure is increased.

Valve Sizing and Selection cont.

n

Pmax = 0.5 (P1 – Pv)

Where:

Pmax = Maximum allowable pressure drop

P1 = Absolute inlet pressure (psia)

Pv = Absolute vapor pressure (refer to psia - Table 2)

Absolute pressure = gage pressure + 14.7

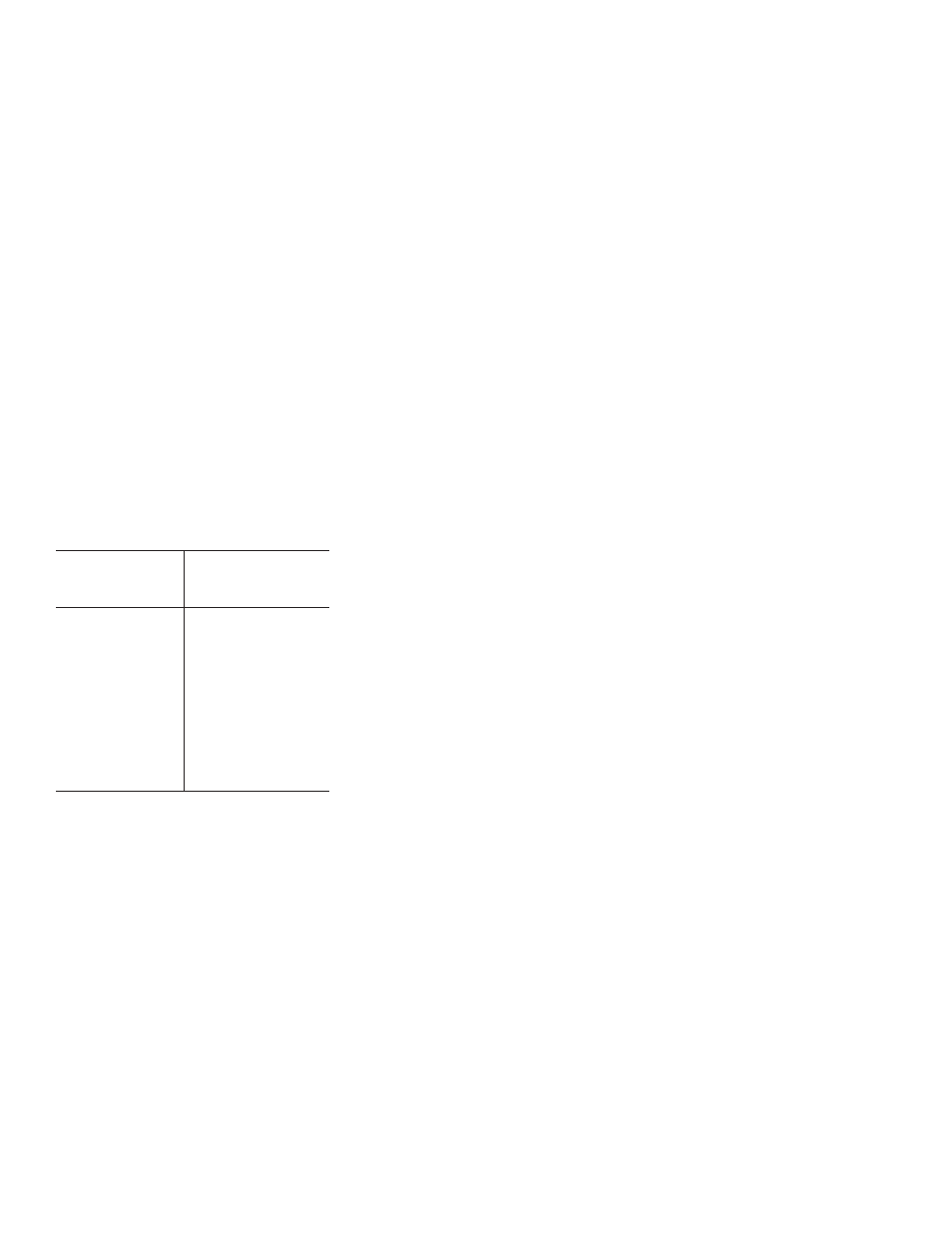

Table-2 Vapor Pressure of Water

Water

Vapor

Water

Vapor

Temp.

Pressure

Temp.

Pressure

(°F)

(psia)

(°F)

(psia)

40

0.12

140

2.89

50

0.18

150

3.72

60

0.26

160

4.74

70

0.36

170

5.99

80

0.51

180

7.51

90

0.70

190

9.34

100

0.95

200

11.53

110

1.28

210

14.12

120

1.69

220

17.19

130

2.22

230

20.78