Application information, Theory of operation – Powers 596 Series Flowrite II Heavy Duty Control Valves - Type MI Mixing User Manual

Page 2

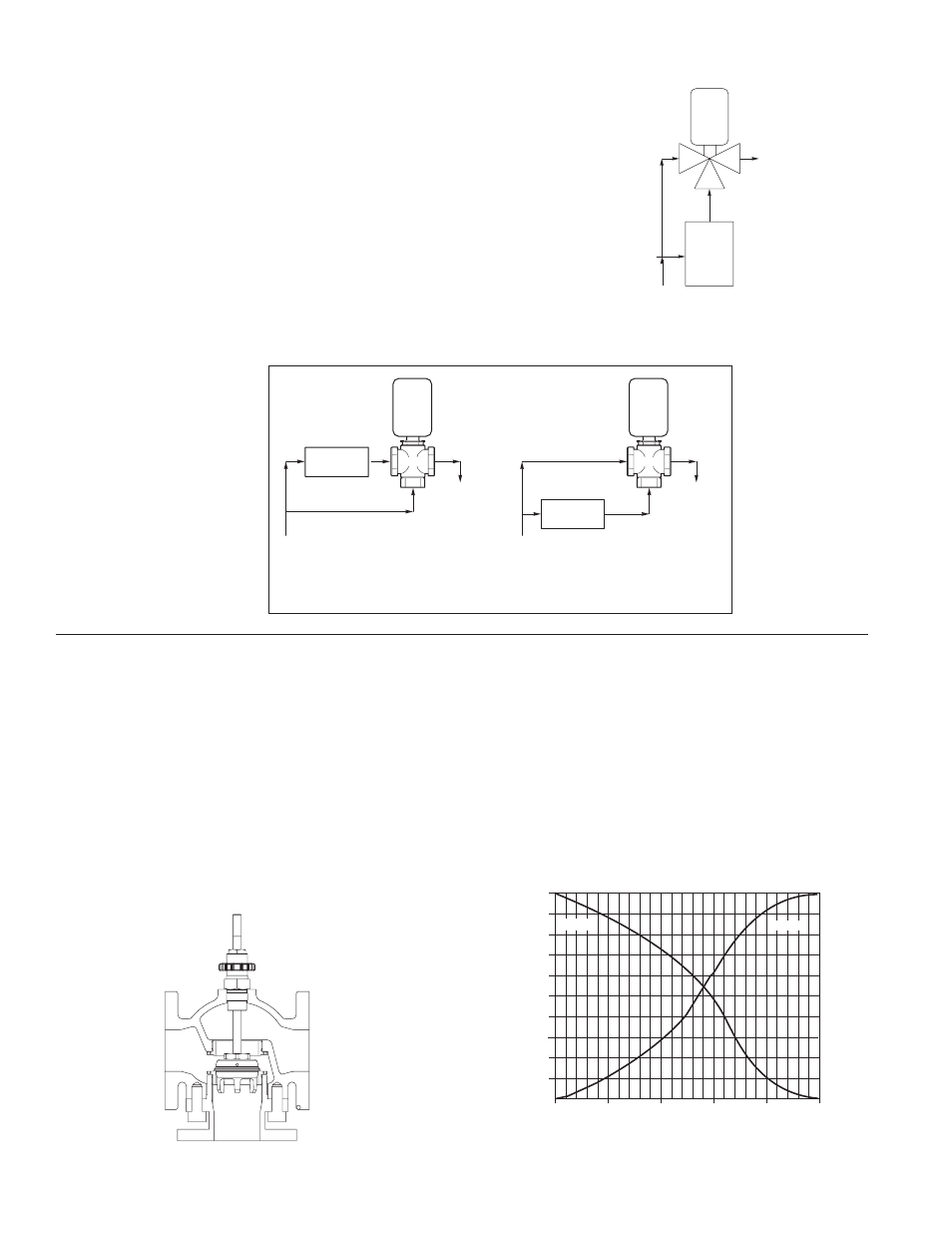

Flowrite II 596MI Valves are used for mixing hot and cold-water

streams or bypassing flow with the valve in the return line. The

controlling instrument positions the mixing valve to obtain the

approximate mixture temperature.

Figure 1 shows an example of a mixing application, a typical

boiler hot water control system. The cold inlet supply is fed to

the upper inlet port (A port) of the valve as well as through the

boiler for production of hot water to be fed into the bottom port

(B port).

Figure 2 shows an example of a bypass application, piping for

control of a heating or cooling coil, with the valve in the return

line. The controlling instrument positions the valve so that the

hot water will bypass the coil when the air is at the proper tem-

perature. A pump is recommended in the coil loop to improve

the heat transfer characteristics of the coil.

Air pressure from the controlling instrument enters the pressure

tight chamber of the actuator between the diaphragm and the

upper housing. An increase in control air pressure causes the

diaphragm to press down on the thrust plate, compressing the

springs and moving the valve stem downward. In the valve, this

reduces the flow through the "B" port and increases the flow

through the "A" port.

Conversely, A decrease in control air pressure reduces the

downward force on the actuator diaphragm, moving the

thrust plate and stem upward. The flow through the "B" port is

increased, and the flow through the "A" port is decreased.

In temperature mixing applications the hot inlet is usually

plumbed to the "A" side port, which will close on loss of signal.

Otherwise, the "B" lower port is used for hot, "A" upper side port

for cold, and the "AB" outlet for the mixed combination (see

Figure 3).

Three-way mixing valves are designed so that the flow from

either of the inlet ports to the outlet is approximately linear,

which means the total flow from the outlet is almost constant

over the stroke of the valve stem. See Figure-4 for typical flow

characteristics of 596 MI.

Application Information

n

Theory of Operation

n

2

Boiler

Hot Water Inlet

Control

Valve

A

AB

B

Cold Water

Supply

Return

Boiler Hot Water Control System

Coil

Valve

Return

Bypass

Supply

Supply

Coil

Bypass

Valve

Return

Stem down flow through coil.

Stem up flow through coil bypass.

Stem up flow through coil.

Stem down flow through coil bypass.

Bypass Piping for Control of a Heating or Cooling Coil

Figure 1

Figure 2

Three-way valve

Rated Flow

Stroke

Stem In

Stem Out

"A" Port

"B" Port

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0%

20%

40%

60%

80%

100%

Rated Flow vs Stroke Diagram

A

B

AB

Figure 3

Figure 4