Valve sizing and selection – Powers 596 Series Flowrite II Heavy Duty Control Valves - Type MI Mixing User Manual

Page 3

NOTE: Supply pressures (inlet) are affected by piping sched-

ule, internal surface conditions, and vertical runs (back pres-

sure) so the actual flowing pressure is best measured at the

point of valve use.

Proportional to Mix Supply Flows

Proportional valves when used to blend two water flows con-

trol the output by varying the water temperature to the heat

exchanger at constant flow. These valves require high pres-

sure drops for good control results. They can be sized for a

pressure drop of 20% of the flowing pressure or equal to 25% of

the pressure drop through the heat exchanger at full flow.

Proportional to Bypass Flow

Proportional mixing valves when used to bypass flow are piped

on the outlet side of the hot water source to throttle the water

flow and thereby control heat output. These valves are usually

selected to take a pressure drop up to 50% of the flowing pres-

sure through the valve.

Valve Sizing and Selection

n

3

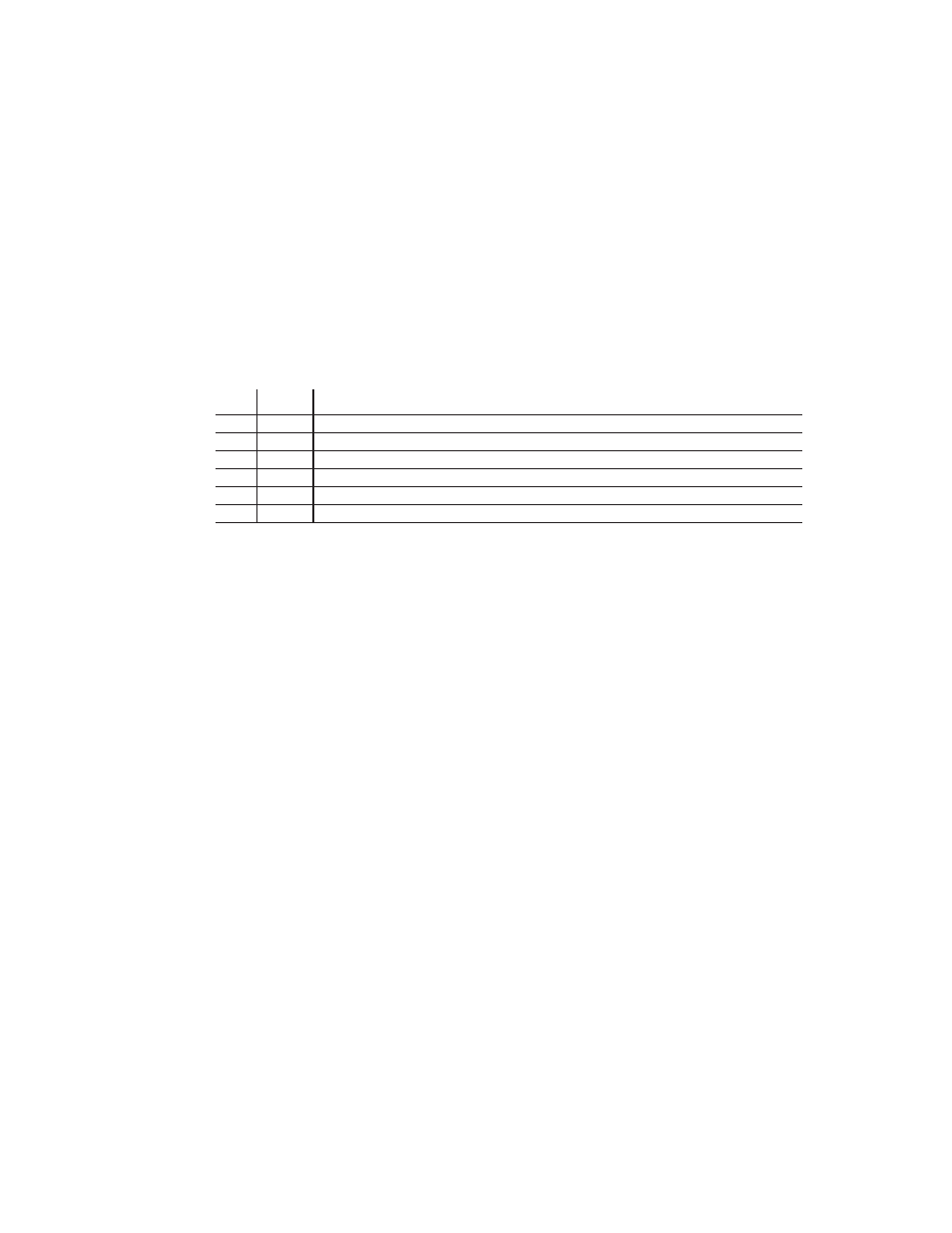

Table - 1 Water Capacity in Gallons Per Minute

Valve

Cv

Size

Rating

Differential Pressure (∆ in psi)

5

10

15

20

25

30

35

40

45

50

2.5

74

165

234

287

331

370

405

438

468

496

523

3

101

226

319

391

452

505

553

598

638

678

714

4

170

380

538

658

760

850

931

1006

1075

1140

1202

5

290

648

917

1123

1297

1450

1588

1716

1834

1945

2051

6

390

872

1233

1510

1744

1950

2136

2307

2467

2616

2758