Flowrite ii maintenance – Powers 593 Series Flowrite II Heavy Duty Bronze Globe Control Valves - Heavy Duty Bronze User Manual

Page 9

TI593UBS

Page 9

FLOWRITE II MAINTENANCE

PACKING REPLACEMENT

The steam service Flowrite II uses spring loaded glass Teflon

®

V-Rings

or Split Ring Graphite. This packing is self lubricating; additional

lubricant is not recommended. Liquid service Flowrite II valves use EP

spring loaded V-ring packing, on which silicone lubricant (part

number 590-165A) is only for installation. For the proper packing kit

see Packing Kit Chart in Appendix.

1. The stem surface must be smooth with no roughness or

imperfections, which can cut, nick, or stretch packing pieces.

Replace stem if imperfections are present.

2. Do not lubricate the bonnet chamber for steam service

packing and EP liquid service packing. Steam service

packing is self lubricating.

3. Protect the beveled or O-ring mating surfaces of valve body and

bonnet. Damaged or nicked bevel or O-ring surface will cause the

valve to leak.

REPACKING PROCEDURE

1. Shut off controlled medium passing through the valve

(steam, water, or other liquid) and remove control signal to

the actuator.

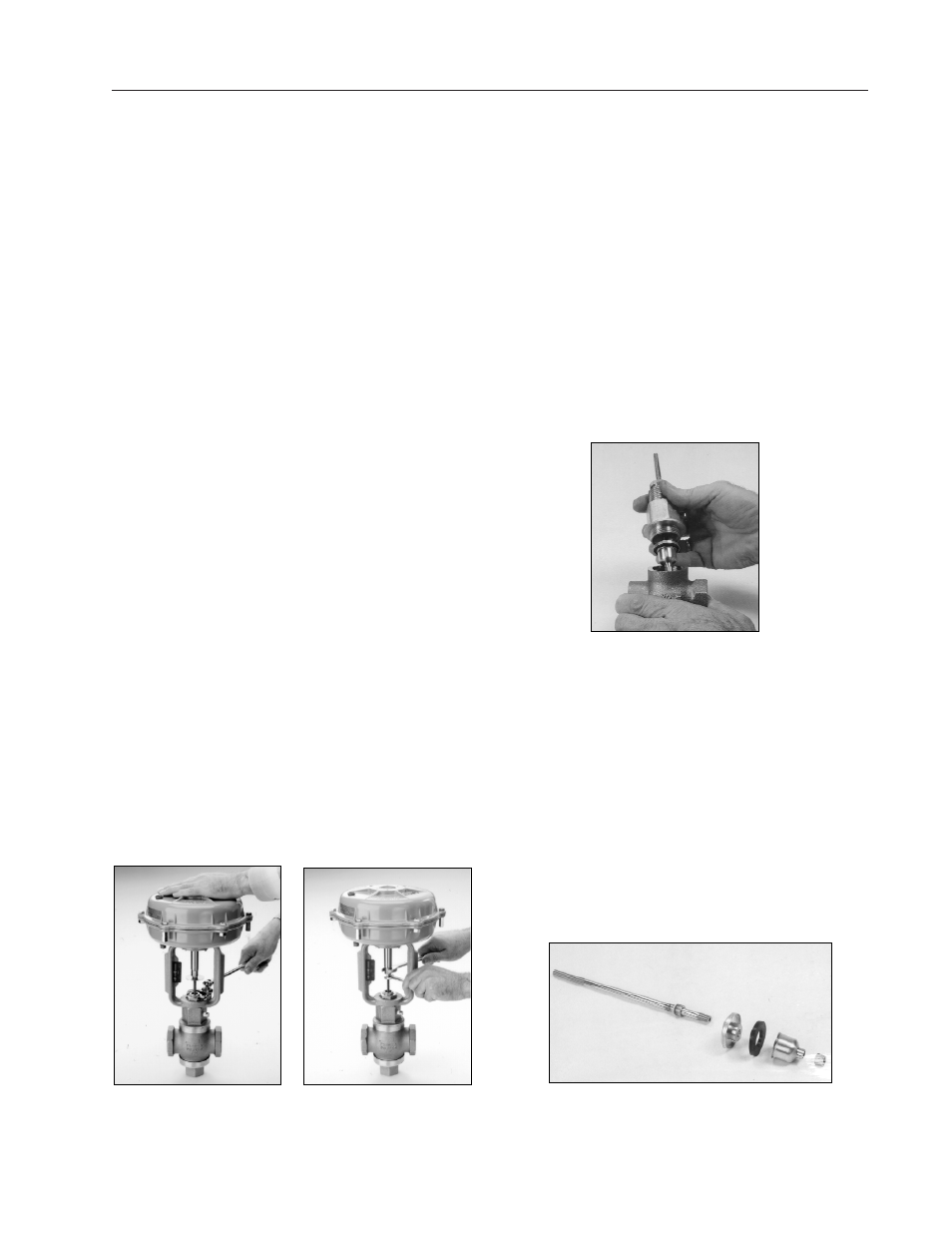

2. Remove bonnet locknut; turn counterclockwise, (Figure 1).

3. Hold the actuator stem in place, loosen the stem locknuts;

turn locknuts counterclockwise. (Figure 2).

4. Place masking tape on valve stem to indicate how far

actuator stem threads onto valve stem.

5. Hold actuator stem and turn valve stem counterclockwise using

locknuts until stems are separated.

6. Remove actuator from valve assembly.

7. Remove packing gland nut. Remove bonnet from body and

push out stem assembly for access to packing.

8. Remove old packing and replace with new parts in packing

kit (see table for kit part numbers). If using EP V-ring

packing, lubricate with silicone grease,

(part number 590-165A).

9. Reassemble valve in reverse sequence.

DISC REPLACEMENT

1. Shut off controlled medium passing through the valve

(steam, water, or other liquid) and remove control signal to

the actuator.

2. Remove bonnet locknut (turn counterclockwise). Hold the

actuator stem in place and loosen the stem in place and

loosen the stem locknuts (turn locknuts counterclockwise).

Place masking tape on valve stem to indicate how far

actuator stem threads onto valve stem. Hold actuator stem

and turn valve stem counterclockwise using locknuts until

stems are separated. Remove actuator from valve assembly.

3. Unscrew the bonnet (turn counterclockwise) and pull

assembly out of the valve body.

4. Remove locknut, throttling plug, and old disc from

stem assembly.

5. Replace with new disc and reassemble in reverse order.

See Figure 3.

SEAT REPLACEMENT

Note: Seats are not replaceable on all valves. If seats are damaged, a

new valve body may be required.

Valve

Replaceable

VE

Yes (special tool required)

SD

No

SS

Yes (special tool required)

WM

No

DB

No

Figure 2

Figure 1

Figure 3

Stem Assembly