Packing – Powers 593 Series Flowrite II Heavy Duty Bronze Globe Control Valves - Heavy Duty Bronze User Manual

Page 11

PACKING

PACKING APPLICATIONS

The packing on a Flowrite II provides a “seal” around the valve stem to

prevent loss of the controlled medium (i.e., steam, water, thylene

glycol solutions, etc.), while allowing the valve stem to pass through

the packing for functional opening and closing of the valve.

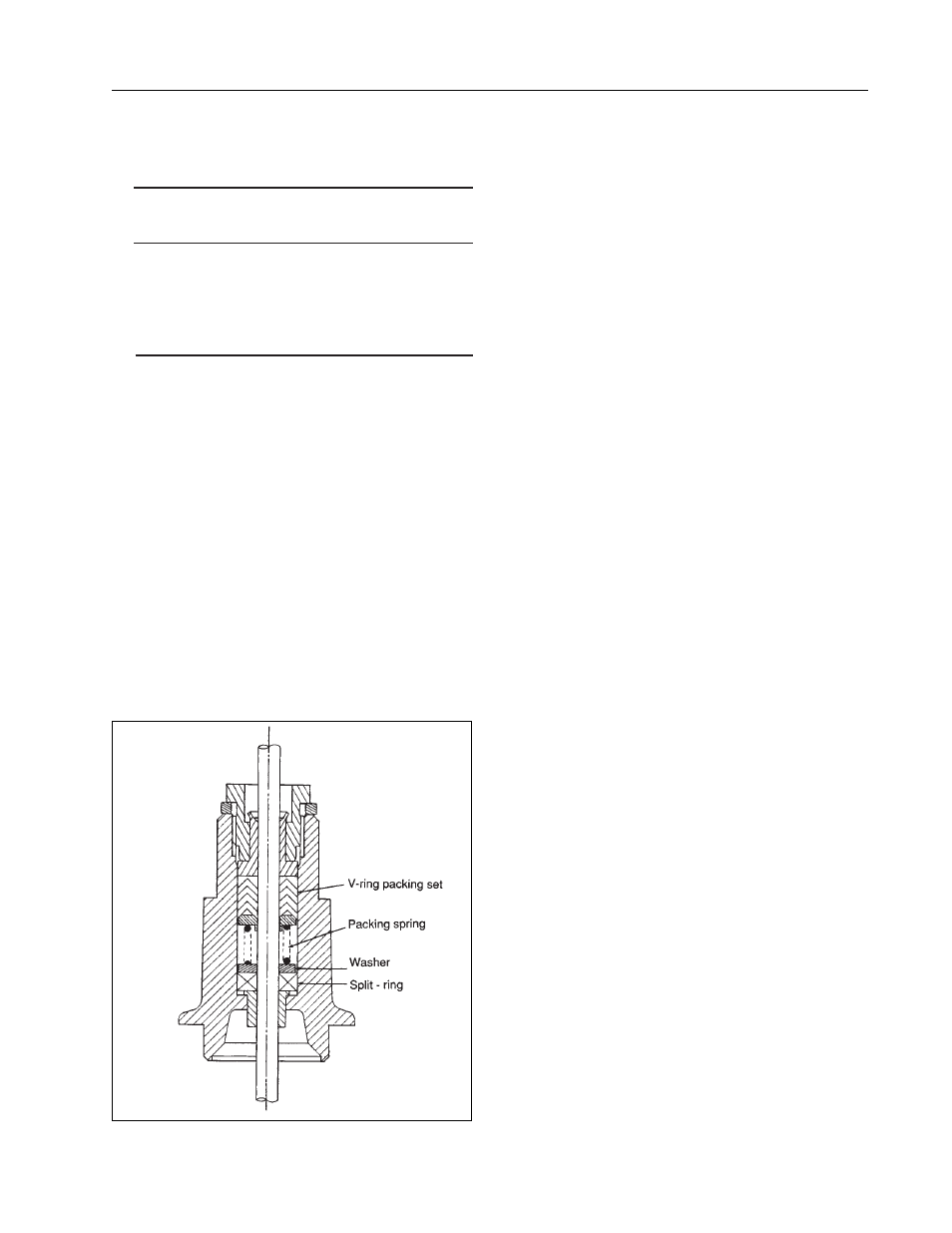

V-RING PACKING

All Flowrite II Utility Valves now utilize the spring loaded V-ring

packing. The teflon V-ring packing does not require lubricant. The EP

V-ring packing must be lubricated with silicine grease (part #590-

165A) prior to installation. Use of lubrication in service is optional.

The packing rings are not split and disassembly of the valve is required

to install or replace this packing.

PARTIAL REPACKING

The top three packing rings can be replaced without disassembling the

valve, to minimize servicing time for critical system operation.

However, replacement of all four packing rings is recommended to

obtain optimum packing performance and life.

Coat new rings with recommended lubricant, slip rings around stem,

staggering cuts, push down as far as possible and tighten packing gland

nut sufficiently to compress the packing rings toward the bottom of

the packing gland. Loosen packing gland nut and readjust to “finger

tight” only. Pack the bonnet with recommended lubricant.

Note: Single set 2-way screwed valves should be

repacked in the closed position.

For complete repacking, see page 9.

Packing Type

Application

Teflon V-Ring

Effective from 200-400°F

(No Lubricant)

Steam: Up to maximum PSI valve rating

Water: Up to maximum PSI valve rating

EP V-Ring

Effective from 0-300°F

Silicone lubricant

Steam: 50 PSI maximum

required for

Water: Up to maximum PSI valve rating

installation,

optional for

service

Figure 1. V-Ring and Split Ring Packing

TI593UBS

Page 11