Metrohm Vision – Diagnostics User Manual

Page 28

26

▪▪▪▪▪▪▪

Before Reference Standardization begins Vision

must establish the instrument configuration and

have it verified by the user. This assures that test

data is sent to the correct location in the

Diagnostic Database.

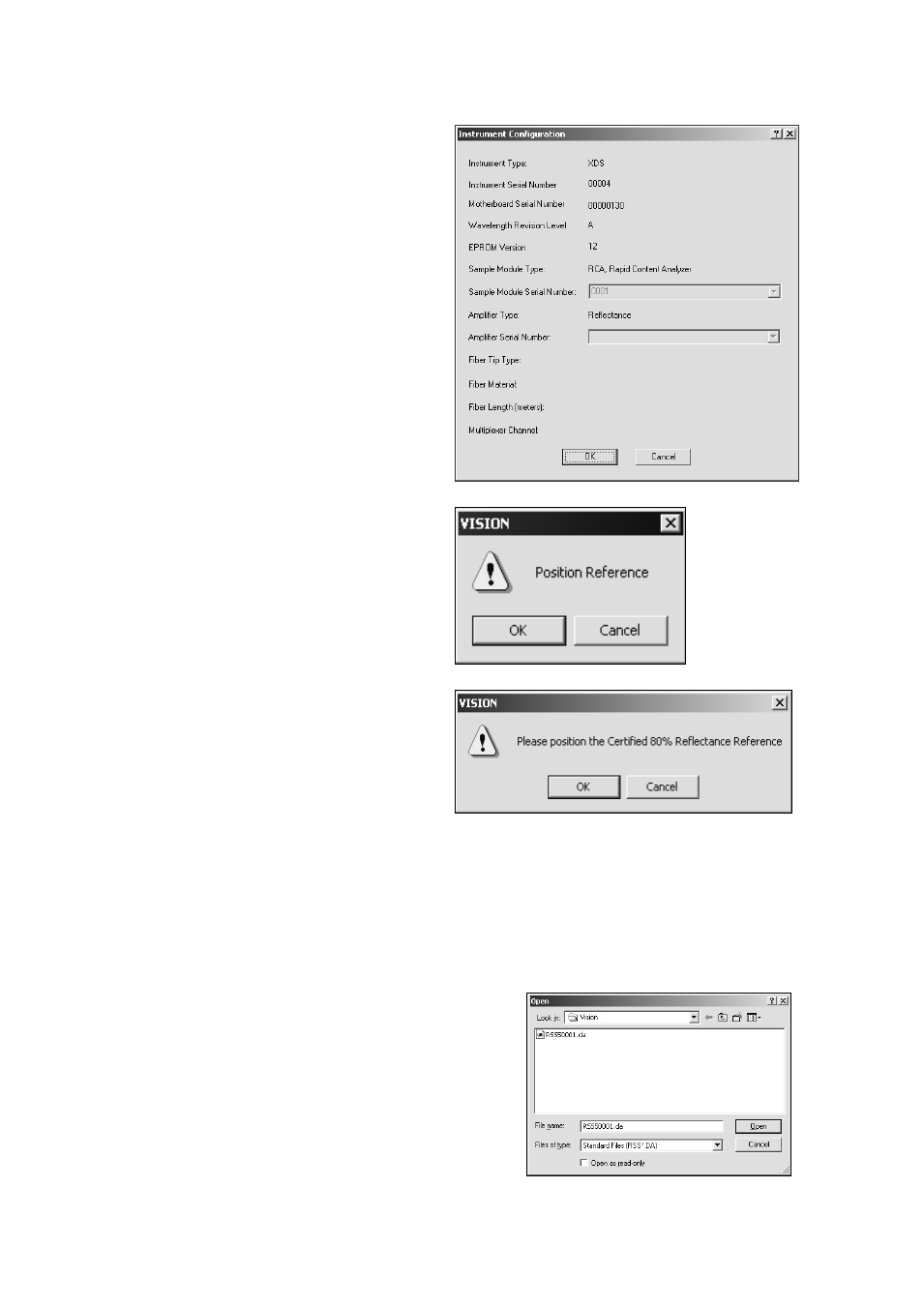

This screen is shown:

If the Sample Module Serial Number field is

empty, locate the sample module serial number

on the side or back of the module. Record the

serial number and enter it in this field.

Click “OK” to accept the instrument

identification.

Vision requests that the user place the ceramic

reference into position. If working with the RCA

or XDS RCA, make sure the cover is closed after

placing reference standard in position.

Click on “OK”. The status bar indicates scan

progress.

Vision requests that the Certified 80%

Reflectance Reference be placed in the sampling

area. For consistency, place the standard with

the calibration label parallel to the holder (RCA

and Sample Transport or other straight line

inside the module.

Note the position of the Certified Reflectance Standard and always use this position.

Place the standard, and click on “OK”.

The Certified 80% Reflectance Reference has been run on the Metrohm master reflectance

instrument. After it is created and loaded, the information is used to apply a correction to the

instrument reference.

Vision requests the Standard File for the Certified 80%

Reflectance Reference. This file is on the diskette or CD

packed with the standards, and may be copied to the

Vision directory for ease of use, as shown here.

The file is named “RSSxxxxx.da”. Click on the file, and then

click “Open”.