Rockwell Automation GV3000/SE AC Bookshelf Drive Hardware Ref, Installation, and Troubleshooting User Manual

Page 87

Compliance with Electromagnetic Compatibility Standards

C-3

C.3.1 Motor Leads

The motor leads must be run in continuous, rigid, conductive conduit,

continuously-screened armored cable, or equivalent. Note that the use of flexible

metal conduit, open wire, or wire in trays is not acceptable. Many flexible metal conduit

products have not been designed for RF containment and are not adequate to

maintain compliance.

All motor leads should have the same cross-sectional area. The maximum allowable

motor lead length from the drive to the motor is 250’ (76m).

A ground (earth) lead, equivalent in size to the motor leads, must be run with the

motor leads from the motor to the drive. Terminate this lead in the drive at the ground

terminal.

Proper glands must be used to terminate the motor conduit/cable. The gland must

secure the cable screen to the conductive surfaces of the drive and motor. A full 360

°

screen termination is preferred.

Follow all instructions supplied with the motor.

C.3.2 Grounding the Drive

Connect the drive/filter assembly to earth ground at the terminal provided (see figures

4.1 and 4.2. The ground wire should be sized per EN-60204-1, Part 5.2

1

, for copper

conductors and EN-60204-1, Part 8.2.2.2

2

, for non-copper conductors. European

Union standards require that the ground wire must be green/yellow according to

EN-60204-1, Part 15.2.2.

3

1

EN-60204-1, Part 5.2: Minimum Cross-Sectional Area of the External Protective

Copper Conductor

2

EN-60204-1, Part 8.2.2.2: Protective Conductors

Copper conductor should be used. If a material other than copper is used, its electrical

resistance per unit length should not exceed that of copper. Non-copper conductors

should not be less than 16 mm

2

in cross-sectional area.

3

EN-60204-1, Part 15.2.2: Identification of the Protective Conductor

For insulated conductors, the two-color combination of Green and Yellow should meet

the following criteria for any given 15 mm length: one of the colors should cover at

least 30% and no more than 70% of the surface, with the other color covering the

remainder of the surface.

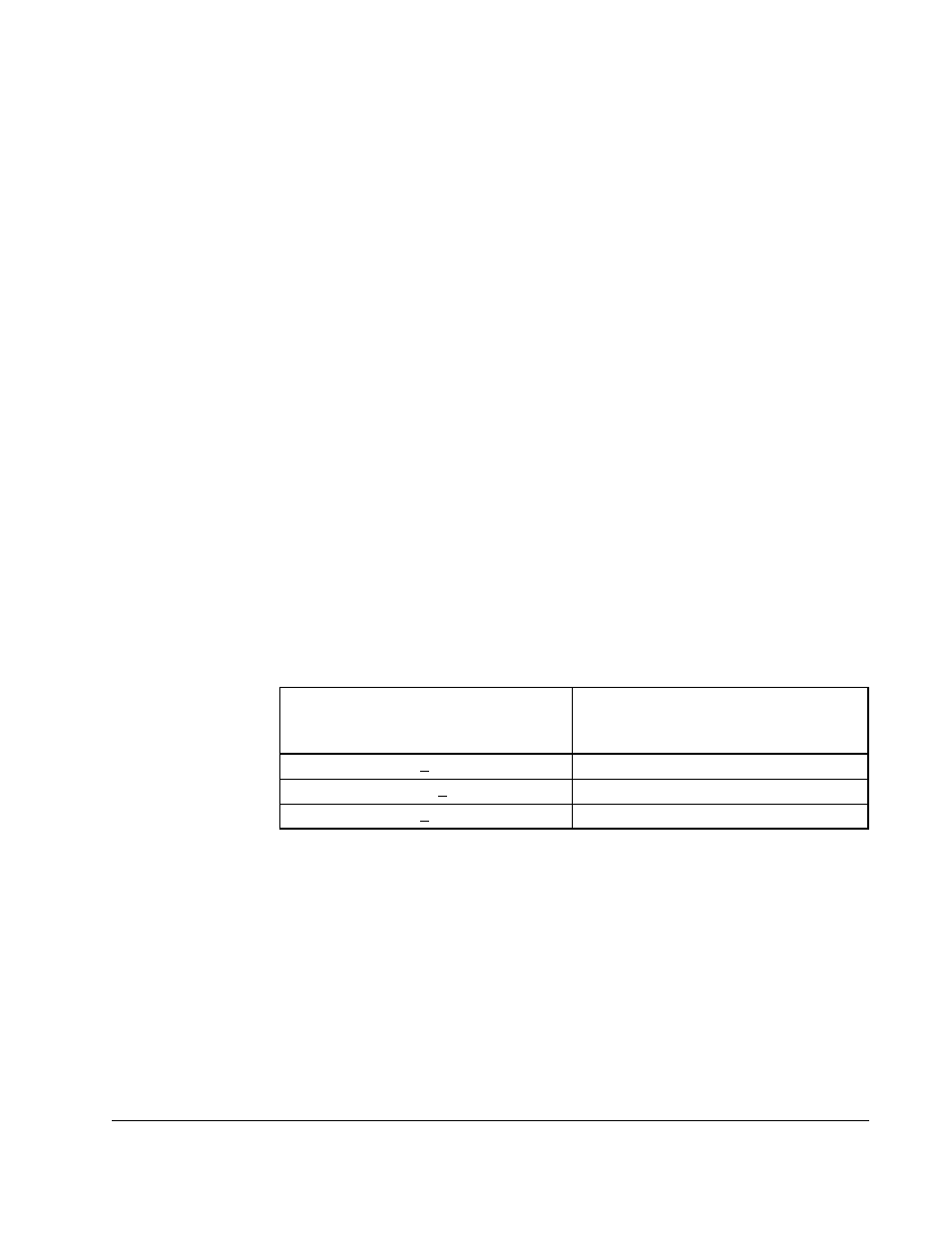

Cross-Sectional Area of Phase

Conductors Supplying the Equipment

(S) (mm

2

)

Minimum Cross-Sectional Area of the

External Protective Conductor (mm

2

)

S < 16

S

16 < S < 35

16

S > 35

S/2