Rockwell Automation WebPak 3000 DC Drives Hardware Reference, Installation and Troubleshooting User Manual

Page 46

4-4

WebPak 3000 DC Drive Hardware Reference

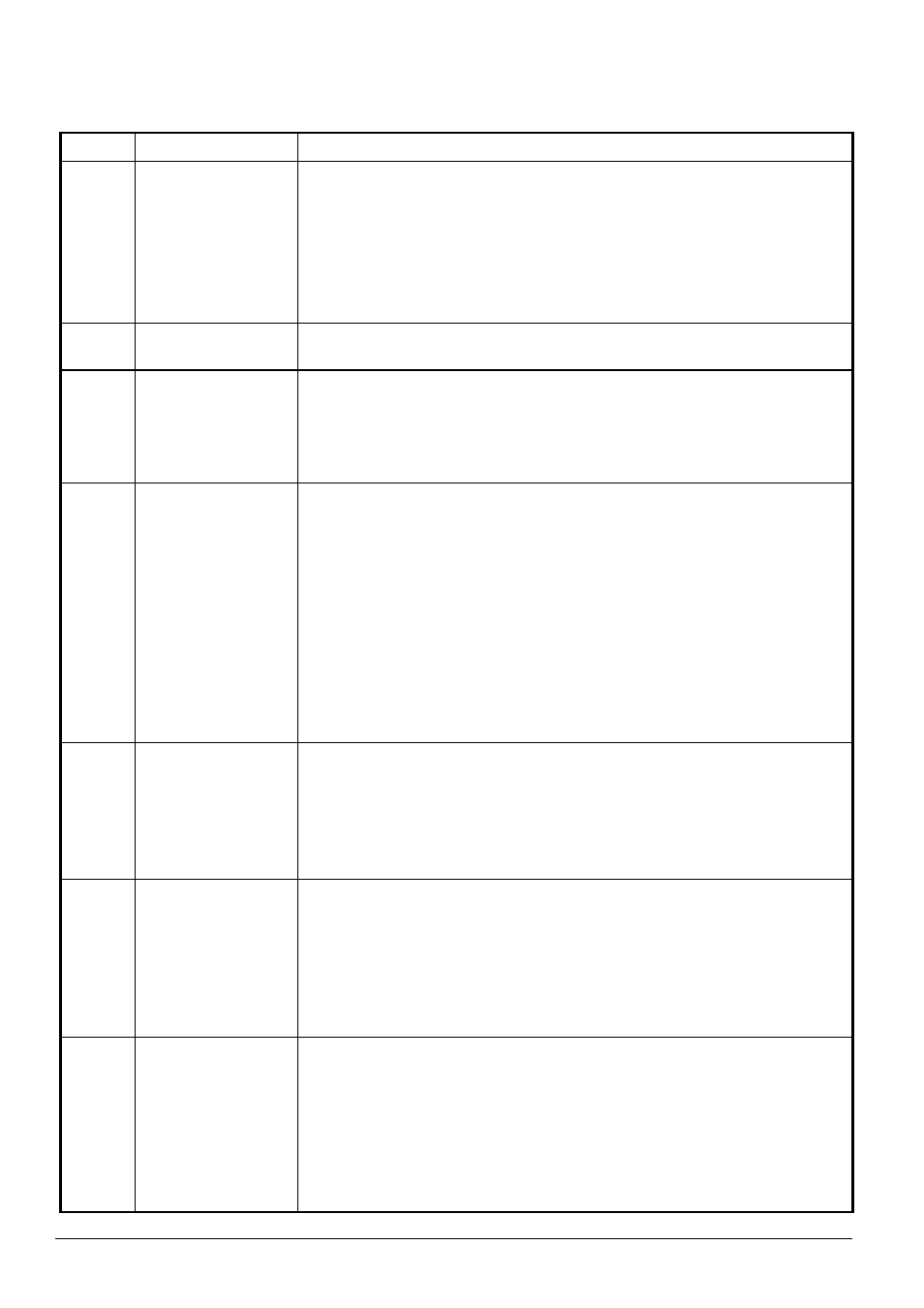

Table 4.1 - Fault Codes (Continued)

CODE

DISPLAY

DESCRIPTION

F00005 SUSTAINED

OVERLOAD

Inverse time overload circuit trip.

Possible causes:

•

Incorrect armature current feedback scaling

(MOTOR RATED ARM

AMPS, MAXIMUM CURRENT, CT TURNS RATIO

and/or J18 not set

properly).

•

Blown field supply fuse(s).

•

Mechanical binding preventing the motor shaft from rotating freely.

F00006 BLOWER MOTOR

STARTER OPEN

This fault is not applicable on European versions WebPak 3000.

F00007 OPEN ARMATURE The motor armature circuit is open.

Possible causes:

•

Motor armature winding not connected or open circuit.

•

Blown inverting fault (DC) fuse.

•

Inverting fault breaker tripped.

F00008

MOTOR

THERMOSTAT TRIP

Motor thermostat indicates high temperature. If a motor thermostat is

not used, customer terminal board pins 13 and 14 must be jumpered to

inhibit this fault.

Possible causes:

•

Damaged or disconnected motor thermostat wiring.

•

Inadequate ventilation.

•

Blower motor failure.

•

Incorrect blower rotation.

•

Blocked ventilation slots.

•

Clogged filters.

•

Excessive armature current.

•

One or more thyristors not operating.

F00009

CONTROLLER

THERMOSTAT TRIP

Drive thermostat indicates high temperature.

Possible causes:

•

Inadequate heat sink ventilation.

•

Inadequate cabinet ventilation.

•

Heat sink fan failure.

•

Damaged or disconnected drive thermostat wiring.

F00010

AC LINE

SYNCHRONIZATION

FAULT

Three-phase AC line synchronization circuit failure.

Possible causes:

•

Blown AC line fuse(s).

•

AC line frequency not within required range of 48 to 62Hz.

•

Excessive AC line noise or distortion.

•

Unstable AC line frequency.See

PLL MAXIMUM ERROR

(P.308).

•

Disconnected, loosely connected or damaged J6 ribbon cable.

F00011

OIM

COMMUNICATIONS

TIMEOUT

The regulator board was unable to communicate with the Operator

Interface Module (OIM). (See the previous section 4.5 for a description

of the regulator status LEDs that can pinpoint whether or not the OIM is

communicating).

Possible causes:

•

Disconnected, loosely connected, or damaged interface module/

serial cable.

•

Regulator board failure.