Using output signal timine data, Using output signal timing data – Rockwell Automation 5370 Color CVIM Communications Manual User Manual

Page 27

Chapter 3

Using Local I/O

3–7

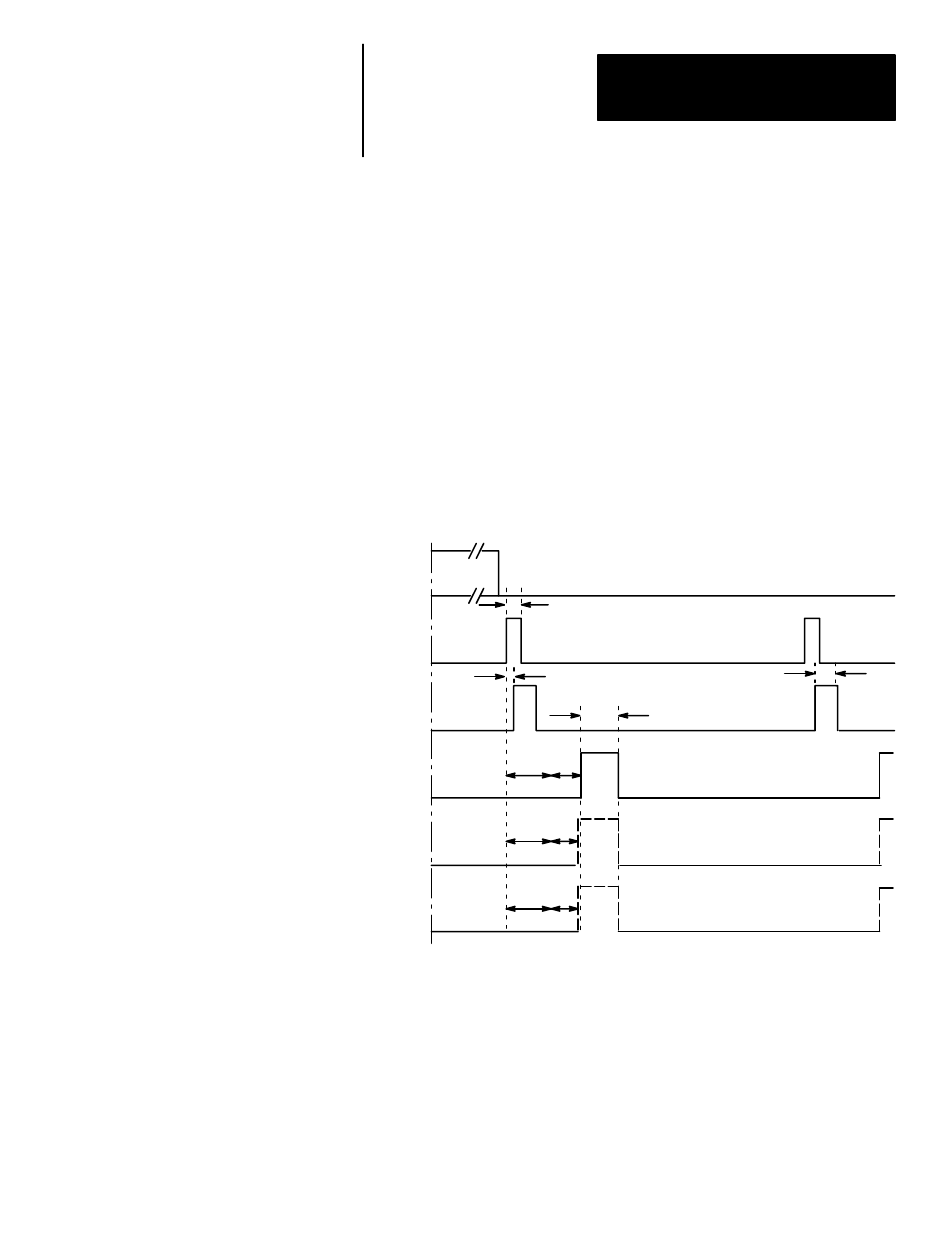

To make proper use of the signal data available to the output lines, you must

first understand the timing relationships that exist between the trigger input

signal (which starts each inspection cycle) and the output signals.

Knowing these signal timing relationships enables you to accurately

synchronize the inspection cycles with your production equipment.

Timing charts (Figures 3.2, 3.3, and 3.4) show the timing relationships in

various circumstances.

Figure 3.2 shows the relationship between the trigger leading edge and the

Strobe, Data Valid, and Results signals, where the last three appear as pulses

whose duration you determine during configuration.

Figure 3.2

Timing Diagram — Pulsed I/O

Strobe

≈

2ms

You can select a

pulse width of 1

to 2000ms

Min. trigger

≈

2ms*

DATA VALID will al-

ways pulse high

when inspection

processing is com-

plete.

MODULE

BUSY

**

***

**

***

**

***

Trigger

pulse #1

Trigger

pulse #2

Trigger

(Input)

STROBE

DATA

VALID

RESULTS

MASTER

RANGE

RESULTS signal will

pulse high if an anal-

ysis tool range limit

is exceeded.

MASTER RANGE

signal will pulse

high if any tool de-

tects a failure con-

dition.

Max. lag

≈

1ms

* As seen by the Color CVIM when the trigger is directly connected through the JMB

board, and not provided by a host device.

** Minimum acquisition time: 17ms for 256x256 and 512x256 Res; 34 ms for 512x512 res.

*** Analysis time (variable).

Using Output Signal

Timing Data