Input image – Rockwell Automation 1746-BLM Blow Molding Module Installation Instructions User Manual

Page 33

Blow-molding Module 33

Publication 1746-IN014B-EN-P - January 2001

Input Image

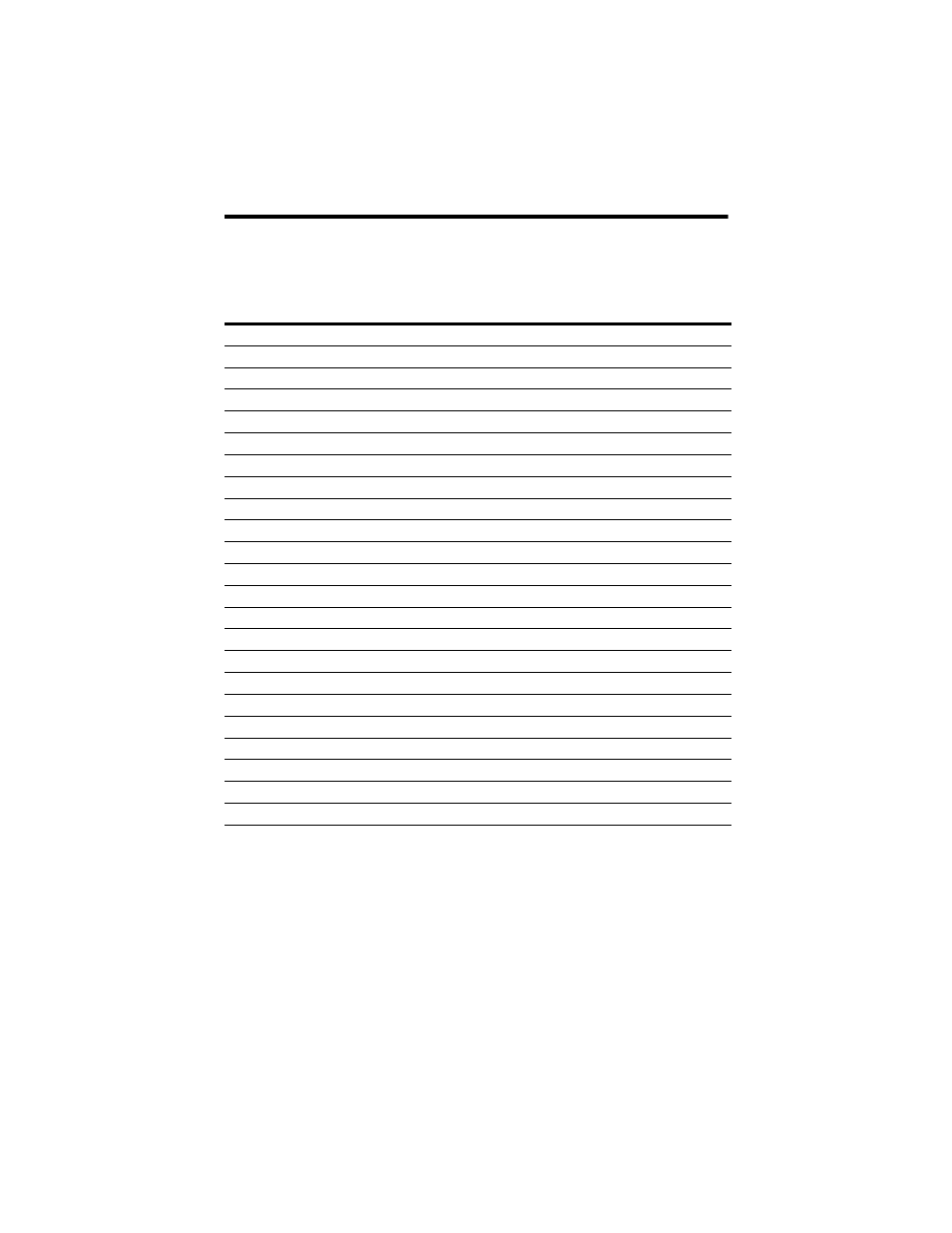

Notes: Error flag value (decimal) -1 = axis control structure address of parameter in error. For additional control structure

information, see page 30.

For description definitions, see page 43.

Addresses for axes 1-4

axis 1 axis 2 axis 3 axis 4 Status-bit Description (=1 for reported status)

0/0

2/0

4/0

6/0

profile enable is set for duration of profile

0/1

2/1

4/1

6/1

follows state of hold-value-0 control bit

0/2

2/2

4/2

6/2

follows state of hold-value-1 control bit

0/3

2/3

4/3

6/3

follows state of hold-value-2 control bit

0/4

2/4

4/4

6/4

verifies completion of structure download

0/5

2/5

4/5

6/5

verifies completion of structure upload

0/6

2/6

4/6

6/6

verifies zero-scale calibration has been recorded

0/7

2/7

4/7

6/7

verifies full-scale calibration has been recorded

0/8

2/8

4/8

6/8

verifies completion of setpoint profile download

0/9

2/9

4/9

6/9

verifies completion of process-variable profile upload

0/10

2/10

4/10

6/10

verifies completion of master setpoint profile download

0/11

2/11

4/11

6/11

verifies completion of interpolated setpoint profile upload

0/12

2/12

4/12

6/12

indicates state of sync input logically ANDed with profile enable bit

0/13

2/13

4/13

6/13

indicates state of synch output

0/14

2/14

4/14

6/14

follows state of parison-weight control bit

0/15

2/15

4/15

6/15

follows state of parison-velocity control bit

1

3

5

7

error flag (see note)

8

9

10

11

current profile step

12

13

14

15

current setpoint

16

17

18

19

current process variable

20

21

22

23

current control variable

24

25

26

27

current dac output

28

29

30

31

current adc input