Error and status indications on the leds – Rockwell Automation 442L-SFZNMN SafeZone Mini Safety Laser Scanner User Manual User Manual

Page 54

52

Rockwell Automation Publication 10000337275 Ver 01—October 2014

Chapter 11

Diagnostics

Error and status indications on

the LEDs

This section describes the meaning of the error and status indications of the LEDs and how you can respond. You will find a

description of the indicators in Chapter 3, “Status indicators” on page 14, the connections for the outputs of the SafeZone

Mini in Chapter 6, “System connection” on page 40.

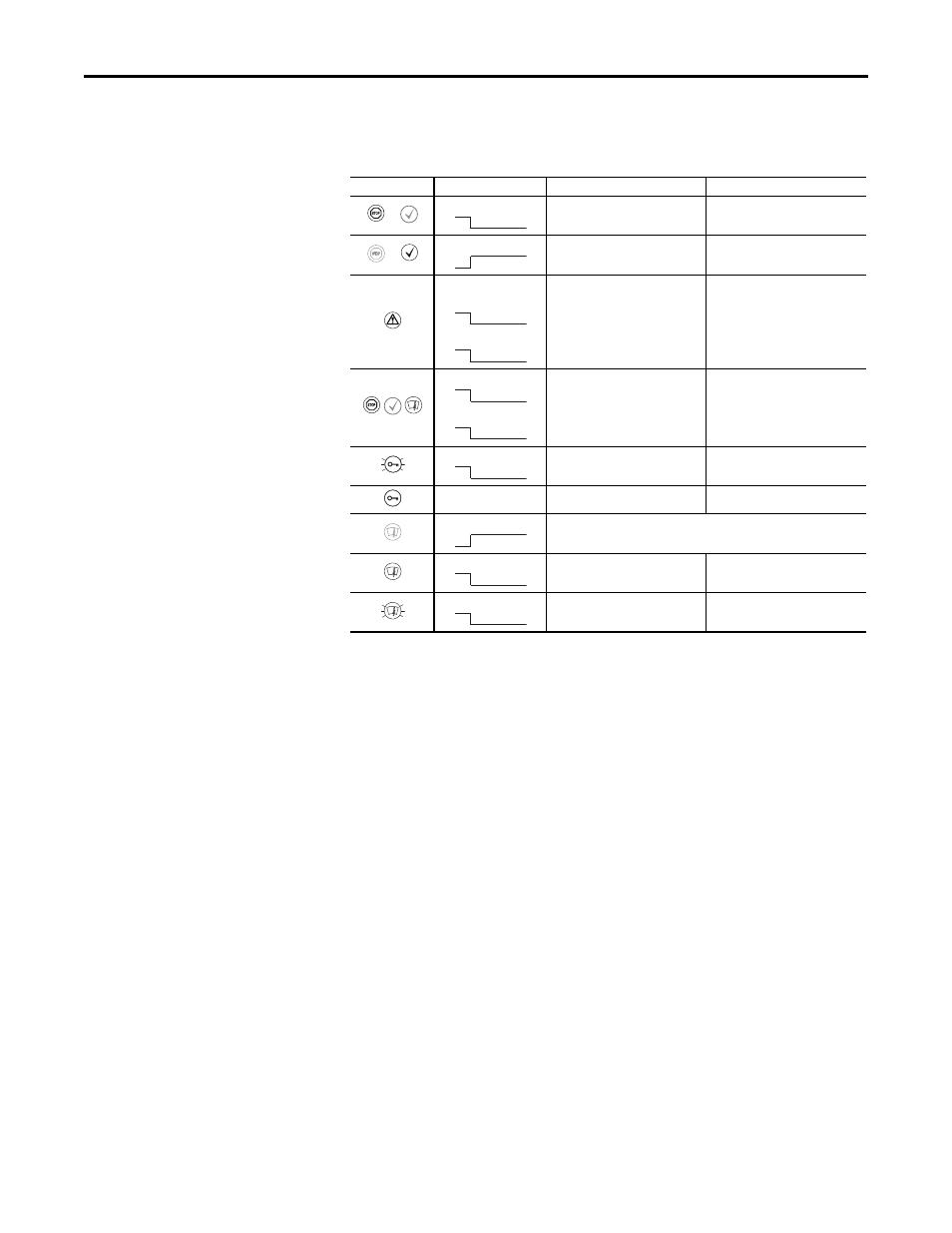

Table 14: Error and status indications of the

LEDs on the SafeZone Mini

If warning field 1 is infringed.

If this is configured as the output for warning field 2 and warning field 2 is infringed.

If this is configured as the output for “Reset required.”

If this is configured as the output for a contamination error/warning.

If this is configured as the output for a contamination error.

If this is configured as the output for a contamination warning.

Error and status indications on

the sevensegment display

This section explains the meaning of the error indications on the sevensegment display and how to respond to the

messages. You will find a description of the positions and symbols on the SafeZone Mini in Chapter 3, “LEDs and

sevensegment display” on page 14.

The lock-out operational status

In case of certain faults or an erroneous configuration, the device can go into the lock-out operational status. To place the

device back in operation, proceed as follows:

Rectify the cause of the fault per Table 15 on page 53.

Switch off the power supply for the SafeZone Mini, wait at least three seconds and then switch back on the power

supply.

Or:

Restart the safety laser scanner with the aid of the SCD software.

Display

Output level

Possible cause

Rectification of the error

At the OSSDs

Object in the protective field, OSSDs

in the OFF state

No error

At the OSSDs

Protective field unoccupied, OSSDs

in ON state

No error

At the warning field

output

On the universal I/O

Object in one of the warning fields

No error

At the OSSDs

On the universal I/Os

No operating voltage or voltage too

low

Check the voltage supply and

activate, if necessary.

On the universal I/O

Reset required

Operate the control switch for

restart.

No level change

Restart delay is counting down.

No action is required.

On the universal I/O

No error

On the universal I/O

Optics cover contaminated, no

operation

Clean the optics cover.

On the universal I/O

Optics cover contaminated, still in

operation

Clean the optics cover.