Chapter, Commissioning – Rockwell Automation 442L-SFZNMN SafeZone Mini Safety Laser Scanner User Manual User Manual

Page 49

Rockwell Automation Publication 10000337275 Ver 01—October 2014

47

Chapter 9

Commissioning

Chapter

9

Commissioning

Initial commissioning

Commissioning requires a thorough check by qualified safety personnel!

Before you operate a system protected by the SafeZone Mini safety laser scanner for the first time, make sure that the

system is first checked and released by qualified safety personnel. The result of the test must be documented. Please read

the notes in Chapter 2, “On safety” on page 6.

Prior to releasing the machine, check whether the access to the hazardous area or the hazardous point is completely

monitored by the protective devices.

Also after approval of the machine, at regular intervals (e.g. in the morning prior to starting work) check whether the

OSSDs (on the SafeZone Mini, a safety laser scanner connected or on a safety controller) switch correctly to the OFF

state as soon as there is an object in the protective field. This test should be performed along all protective field

boundaries as per the specific regulations for the application (see Chapter 9, “Test notes” on page 47).

Power-up sequence

After power up the SafeZone Mini runs through a power up cycle. During the power up cycle, the sevensegment display

indicates the device status.

During the initial commissioning of an SafeZone Mini the following indications are possible:

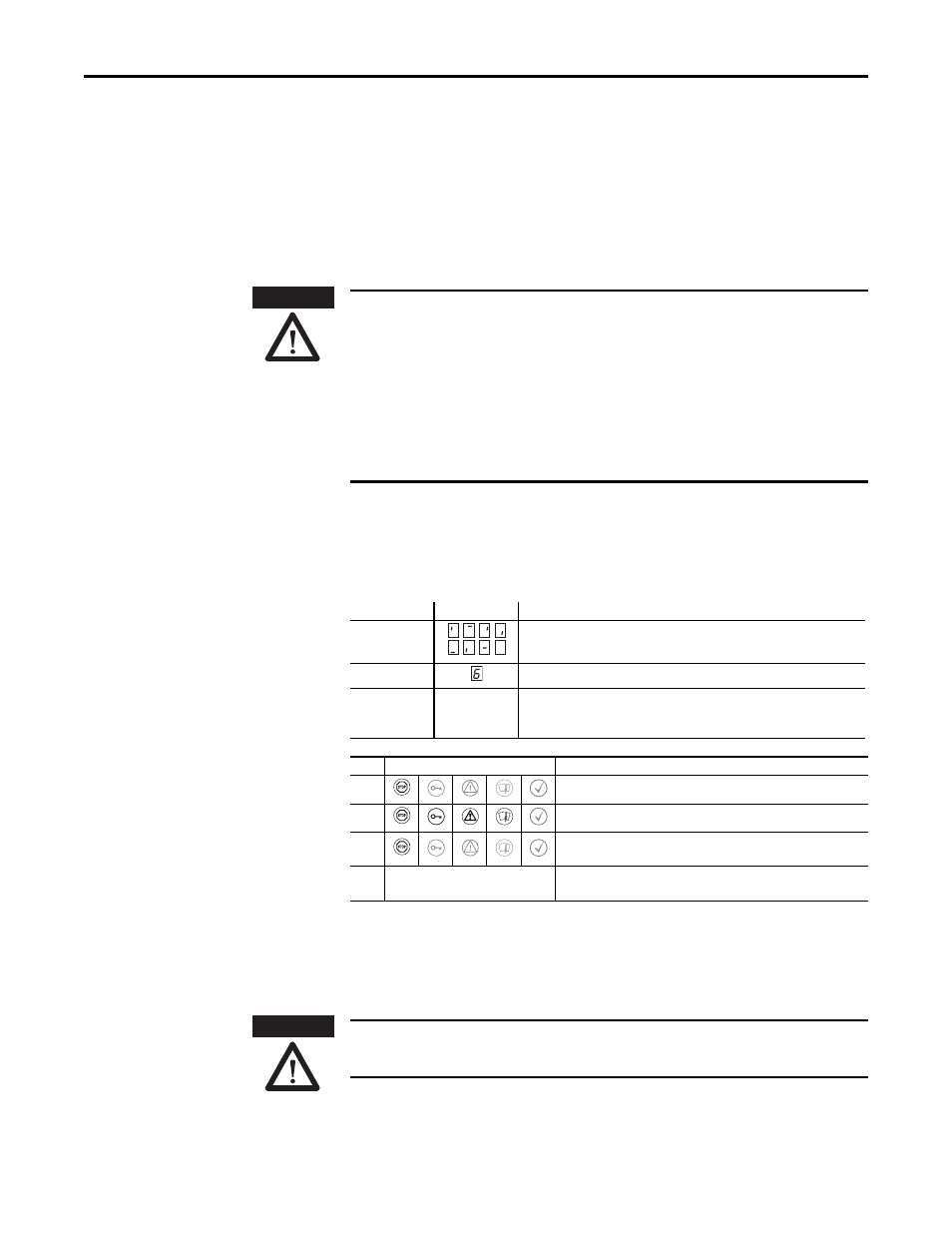

Table 12: Sevensegment display during and after

the power up sequence on initial commissioning

Table 13: LED indication of the SafeZone Mini after

the power up sequence

Test notes

Pre-commissioning tests

The purpose of the pre-commissioning tests is to confirm the safety requirements specified in the national/international

rules and regulations (EC conformity). This applies particularly to the safety requirements in the machinery directive or

work equipment directive.

Ensure that you do not place anybody at risk during initial commissioning of the machine!

Always expect that the machine, system or the protective device does not yet behave as you have planned.

Ensure that there are no persons in the hazardous area during initial commissioning.

ATTENTION

Step

Display

Meaning

1

Power-up cycle, testing the sevensegment display. All segments are activated

sequentially.

2

Power up cycle, during initial commissioning: device in configuration mode

Other display

Safety lock activated. Malfunction in external conditions or in the device itself.

See Chapter 11, “Error and status indications on the sevensegment display” on

page 52.

.

.

Step

Display

Meaning

1

Device self-test

2

Device self-test

3

Device status: waiting for configuration or object in the protective field,

OSSDs in the OFF state

Other display

Safety lock activated. Malfunction (see Chapter 11, “Error and status

indications on the LEDs” on page 52)

ATTENTION