Rockwell Automation 442L-SFZNMN SafeZone Mini Safety Laser Scanner User Manual User Manual

Page 27

Rockwell Automation Publication 10000337275 Ver 01—October 2014

25

Chapter 5

Mounting

For a horizontal stationary application determine …

•

The protective field size to observe the necessary minimum distance.

•

The height of the scan plane.

•

The restart behavior.

•

Measures to protect any areas not covered by the SafeZone Mini.

Note

Once you have defined the protective field size, mark the boundaries of the protective field on the floor. In this way you

will make the protective field boundaries visible for the operator and ease subsequent testing of the protective function.

Protective field size

The protective field must be so configured that a minimum distance (S) to the hazardous area is maintained. This safety

distance ensures that the hazardous point can only be reached after the dangerous state of the machine has been

completely stopped.

Note

You can operate the SafeZone Mini in stationary horizontal operation with 30, 40, 50, or 70 mm (1.2, 1.6, 2.0, or 2.8 in.)

resolution. The maximum protective field range for the SafeZone Mini is given by the resolution.

Ensure that a human leg can be detected with 70 mm (2.8 in.)resolution!

As per EN ISO 13855, mount the scan planes for horizontal stationary applications with 70 mm (2.8 in.) resolution at least

300 mm (11.8 in.) above the floor (see “Height of the scan plane at 70 mm resolution” on page 33).

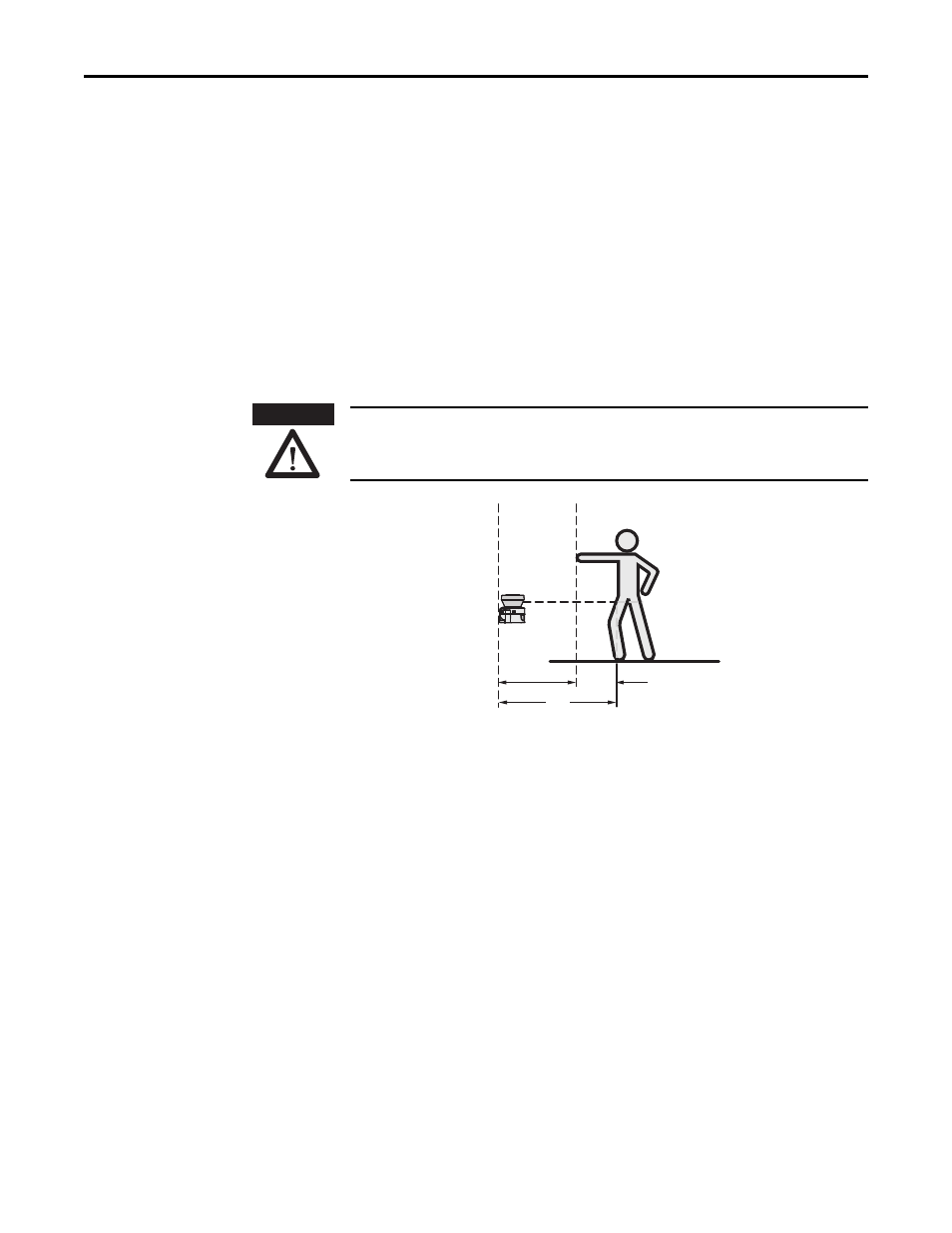

Fig. 15: Minimum distance S

The minimum distance S depends on:

•

Approach speed of the body or parts of the body

•

Stopping/run-down time of the machine or system

(The stopping/run-down time is shown in the machine documentation or must be determined by taking a

measurement.)

•

Response time of the SafeZone Mini

•

Supplements for general measurement errors and any measurement errors related to reflection

•

Supplement for prevention of reaching over

•

Height of the scan plane

•

Possibly the time for switching between the monitoring cases

How to calculate the minimum distance S (see EN ISO 13855):

First, calculate S using the following formula:

S

= (K × (T

M

+ T

S

)) + Z

G

+ Z

R

+ C

Where …

K

= Approach speed (1600 mm/s (63 in./s), defined in EN ISO 13855)

T

M

= Stopping/run-down time of the machine or system

T

S

= Response time of the SafeZone Mini and the downstream controller

Z

G

= General safety supplement of the SafeZone Mini = 100 mm (3.94 in.)

Z

R

= Supplement for measurement error related to reflection

C

= Supplement for prevention of reaching over

ATTENTION

Dangerous state

K x (1

M

+ 1

s

)

2

G

+ 2

R

+ O

S