Trip and warning troubleshooting procedures – Rockwell Automation 193-EDN E1Plus Overload Relays - DeviceNet Module User Manual

Page 47

Publication 193-UM006A-EN-P – October 2005

Troubleshooting 5-7

Trip and Warning

Troubleshooting

Procedures

The following table lists the possible causes for each trip type and the

recommended action to take.

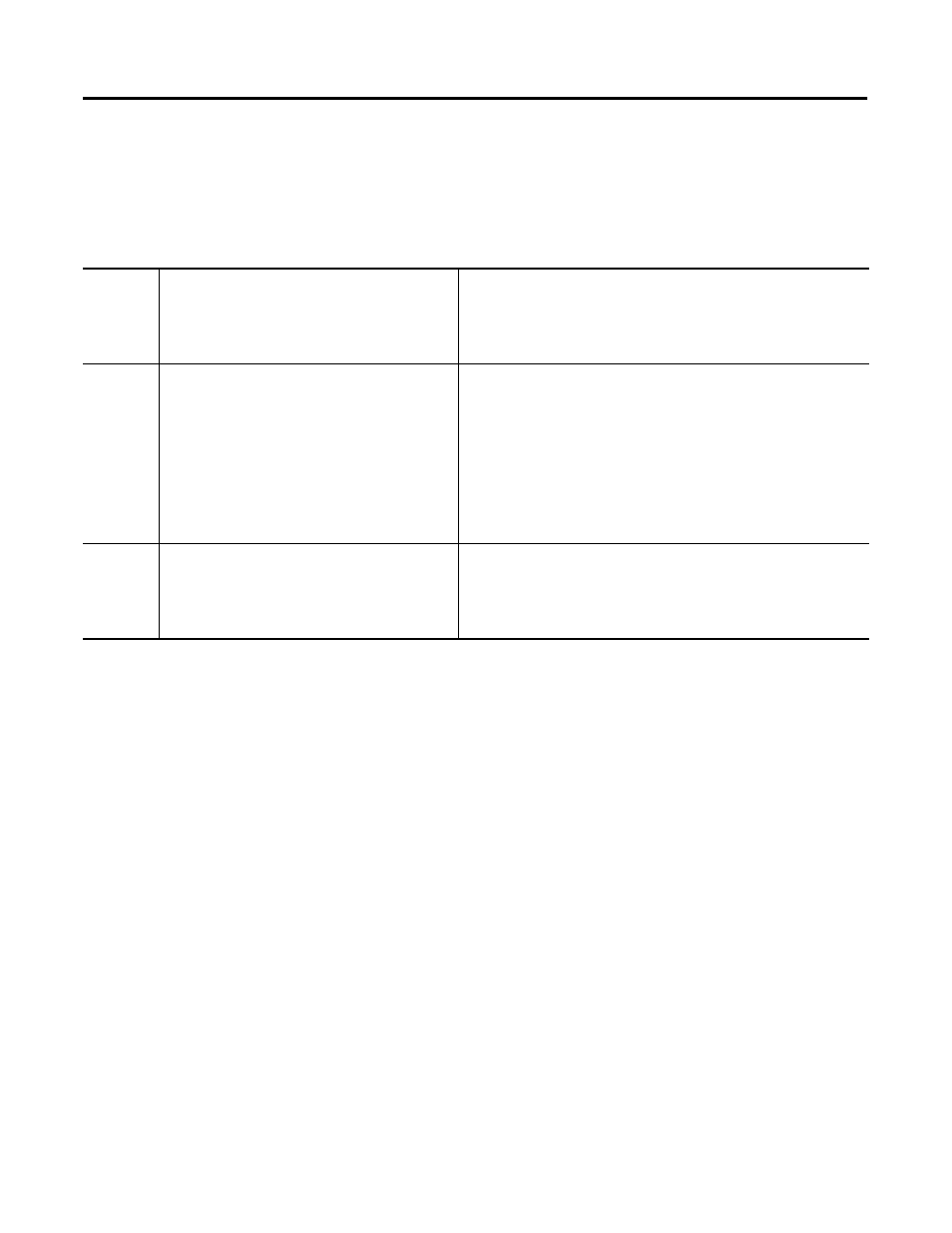

Table 5.3 Trip/Warn LED Troubleshooting Procedures

Overload

1. Motor overloaded

2. Improper setting

1. Check and correct source of overload (load, mechanical

transmission components, motor bearings).

2. Set FLA dial and trip class to match the motor and application

requirements.

Phase Loss

1. Missing supply phase

2. Poor electrical connection

3. Contactor operation

4. Improper device type

1. Check for open line (i.e. blown fuse).

2. Check all power terminations from the branch circuit-protecting

device down to the motor for proper tightness. Ensure that the

overload connection to the contactor is secure.

3. Inspect contactor for proper operation.

4. Bulletin 193S or 592S are required for single-phase

applications.

Jam

1. Motor current has exceeded the

programmed jam level

2. Improper parameter settings

1. Check for the source of the jam (i.e. excessive load or

mechanical transmission component failure).

2. Parameter 20, Jam Trip Level, is set too low for the application.

Check to ensure that the FLA dial is set correctly.