Figure 22 - dip switch & rotary switch locations – Rockwell Automation 150 SMC Quick Start Manual User Manual

Page 36

34

Rockwell Automation Publication 150-QS003D-EN-P - November 2013

Chapter 3 Programming

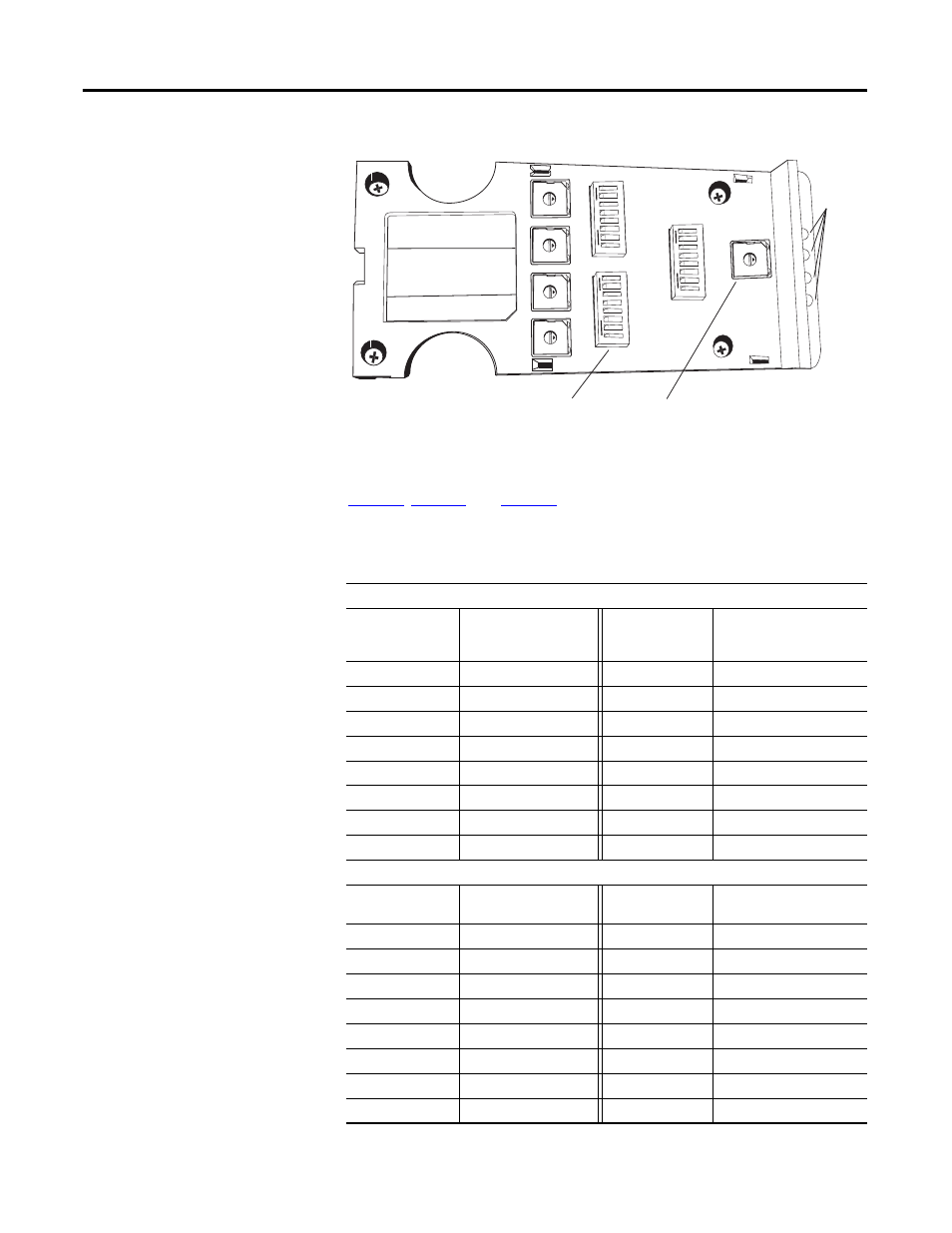

Figure 22 - DIP Switch & Rotary Switch Locations

The Cat. No. 150-SM6 PCM contains five rotary switches, S1…S5, each with

designations 0…F and three banks of ON/OFF 8-switch DIP switches.

, and

define the functions of the five rotary switches.

Table 10 - Rotary Switch Position Settings & Resulting Values — Torque and

Current Limit Configurations

S1 = Initial Torque Configuration — Controller Parameter 51

Position Setting

Resulting Initial

Torque Value

[% motor torque]

Position Setting

Resulting Initial Torque

Value

[% motor torque]

0

10

8

58

1

16

9

64

2

22

A

70 (default)

3

28

B

76

4

34

C

82

5

40

D

88

6

46

E

94

7

52

F

100

S2 = Current Limit Configuration — Controller Parameter 53

Position Setting

Resulting Current

Limit Value [% FLC]

Position Setting

Resulting Current Limit

Value [% FLC]

0

200

8

360 (default)

1

220

9

380

2

240

A

400

3

260

B

420

4

280

C

440

5

300

D

460

6

320

E

480

7

340

F

500

S1

S1

0

F

E

D

C

B

A

98

7 6

5

4

3 2

1

0

F

E

D

C

B

A

98

7 6

5

4

3 2

1

0

F

E

D

C

B

A

98

7 6

5

4

3

2

1

0

F

E

D

C

B

A

98

7 6

5

4

3 2

1

CAT.

150-SM6

SER.

A

SMC-50 PARAMETER CONFIGURATION

S1 Initial Torque

S2 Current Limit

S3 Ramp Time

S4 Stop Time

S5 Motor FLC

MFC LOC MFG DATE

FACxx yy/mm/dd

S4

S4

S3

S3

S2

S2

OPENOPEN

1 2 3 4 5 6 7 8

1 2 3 4

5 6 7 8

OPENOPEN

1 2 3 4 5 6 7 8

1 2 3

4 5 6 7

8

OPENOPEN

1 2 3 4 5 6 7 8

1 2 3 4

5 6 7 8

I/O I/O

I/OI/O

DEVICEDEVICE

DEVICE DEVICE

PROTECTIONPROTECTION

PROTECTION PROTECTION

0

F

E

D

C

B

A

98

7 6

5

4

3 2

1

S5

S5

Rotary Switch

DIP Switch

Diagnostic

LEDs