Steriflow SC30 Series User Manual

Page 2

S

ample

C

oolerS

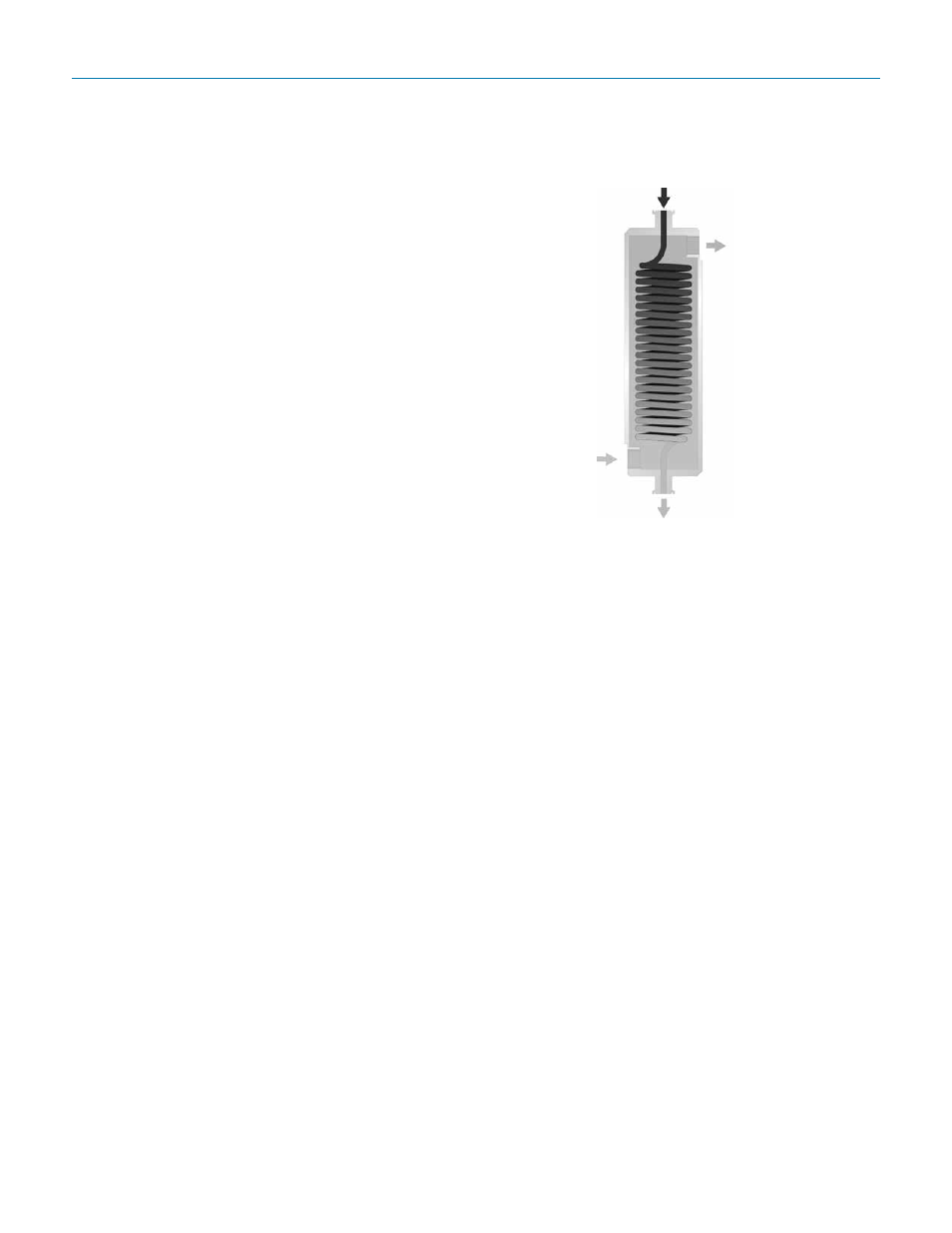

Steriflow's range of sample coolers allow clean steam

and high purity water samples to be taken quickly

and easily while maintaining a sterile testing environ-

ment. The SC50 and SC60 units are designed to be

mounted at the sampling point, while the SC30 is a

free-standing portable unit. All models can be oper-

ated with chilled water as the cooling medium.

Where the quality of the cooling water may cause

fouling of the coil, the SC50 can be easily disassem-

bled for cleaning. A wide range of ancillary products

are available for use with all models of sample cooler.

p

roduCt

F

eatureS

• 316/316L Stainless Steel construction

• High efficiency

• Free draining designs

• Fully sterilizable/autoclavable

S

tandardS

• Where applicable, all sample cooler models

comply with ASME BPE criteria

• All sample cooler models are CE compliant

under the SEP category of the PED directive

o

ptionS

• Electropolish

C

leaning

& p

aCkaging

• All sample coolers are cleaned after

manufacture, capped, sealed in a polythene

bag and individually boxed

t

ypiCal

a

ppliCationS

• Continuous or select point steam sampling

• Point-of-use cooling

• In-line conductivity monitoring of clean

condensate

• Cooling of pump seal water

S

ample

C

ooler

o

peration

o

peration

The cooling medium passes through the center shell of

the coil. A hand regulating valve (SV) is used to throttle

the sample medium flow through the tubing coil. Cooling

water is passed through the shell of the unit in an opposing

direction to the sample medium in order to ensure opti-

mum efficiency. The heat energy of the sample medium is

absorbed by the flowing cooling water, resulting in a drop in

the sample temperature.

Where steam is the sample medium, the cooling water will

first absorb the steam's latent heat content, condensing

it back to water. Further heat transfer as the condensate

passes through the coil will reduce its sensible heat/tem-

perature prior to discharge.

C

apaCity

• Pure/Clean Steam: All models will condense approxi-

mately 22 lbs/hr (10 kg/h) of steam from 43.5 psig (3

barg) to 86°F (30°C) condensate with 0.1 l/s of cool-

ing water. The cooling water outlet temperature will

increase from 68°F to 113°F (20°C to 45°C) during

operation at these conditions. Note: Steriflow can com-

puter model typical testing conditions for all units upon

request.

• WFI: All models will cool approximately 66 lbs [30 kg/

hr (30L/hr)] of WFI from 185°F(85°C) to 86°F (30°C)

using 0.2 L/s of cooling water at 68°F (20°C).

cooling

water inlet

cool clean condensate or WFI

cooling

water outlet

clean steam, WFI

inlet

-2-

d

oCumentation

The following documentation is shipped with each

order:

• Steriflow Unicert

— Traceable Material Heat Number for body and

ferrels

— Certificate of Compliance to FDA and USP

Class VI

— Certificate of Surface Finish

• Final Test Reports and Certificate of Origin

available upon request at time of order