Steriflow JSRLF Series User Manual

Jsrlf series

Steriflow by Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

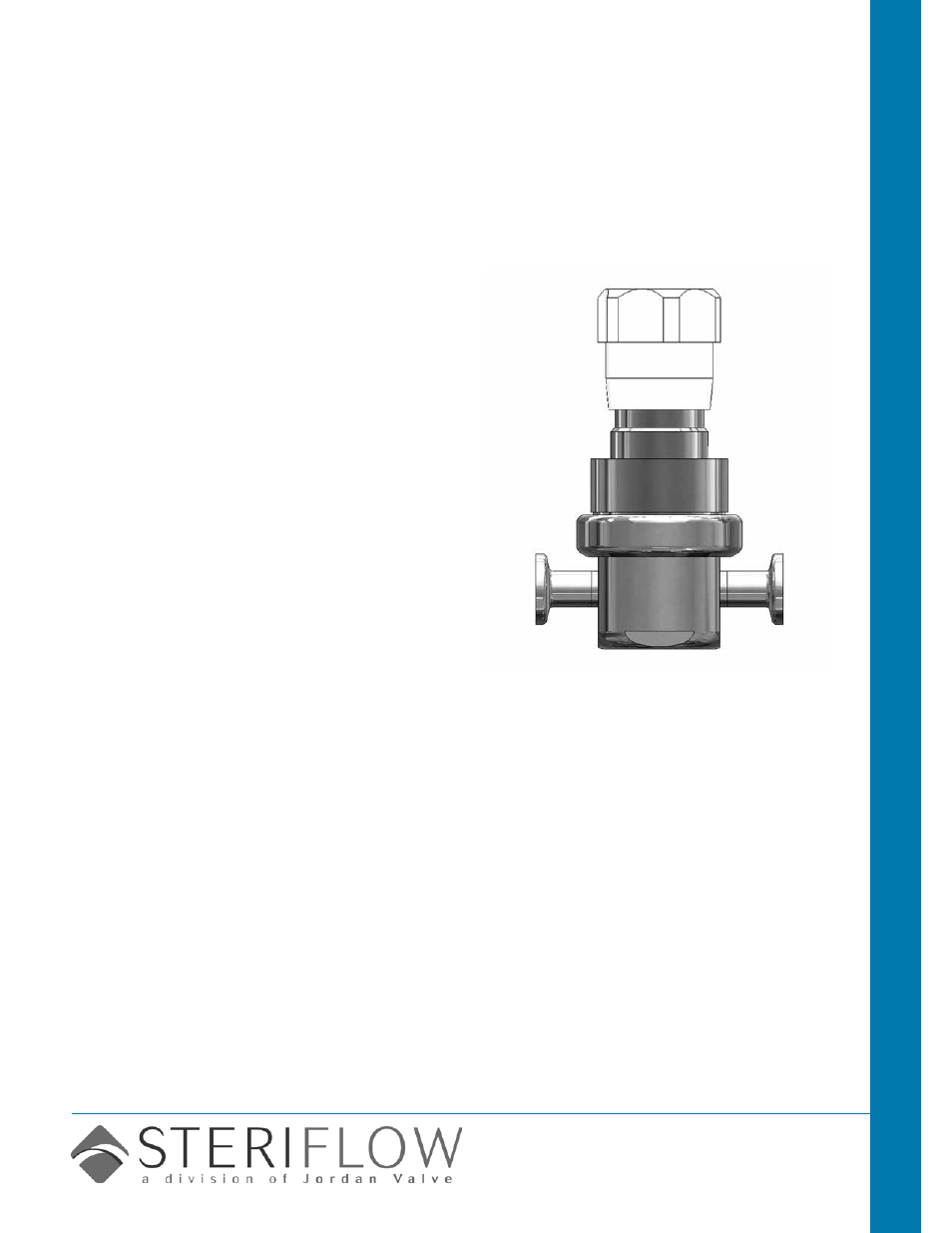

JSRLF Series

Low Flow Pressure Reducing Valves for Bio, Pharma and

High Purity Gas Application

The Steriflow JSRLF Series line of low flow pressure

regulators have the ability to handle very high pressures

and very low flows. These valves are most often used in

biopharmaceutical and pharmaceutical research, and

production facilities for clean gas flow regulation.

The durable valve body and metal trim components are

machined from ASTMA479 316L SST barstock. The

standard finish is ASME BPE SF5 (20Ra micro-inch,

electropolished), SF1 non-electropolished valves are

available. The valve is outfitted with the rugged Jorlon

diaphragm and Teflon or PEEK seats and seals that are

all FDA approved, USP Class VI compliant materials.

These materials of construction enable J-Pure to with-

stand the rigors of SIP and CIP processes if required.

F

eatures

•

Top entry design facilitates in-line cleaning and

maintenance

•

Barstock construction guarantees material

integrity and quality surface finish

•

Four Cv's between 0.01 and 0.2 and six spring

ranges guarantees a valve that will fit your

application

•

Optimized internal volume

•

Proprietary Jorlon diaphragm material provides

exceptionally long life

•

Soft seat material for ANSI Class VI shutoff

•

Can be used on continuous clean steam, and on

non-cavitating fluids.

D

ocumentation

The following documentation is shipped with each

order:

•

Steriflow Unicert

—

Traceable Material Heat Number for body and

ferrules

—

Certificate of Compliance to FDA and USP

Class VI

—

Certificate of Surface Finish

•

Final Test Reports and Certificate of Origin avail-

able upon request at time of order

s

urFace

F

inish

•

ASME BPE SF5 (20 Ra µin (0.5 Ra μm), electropo-

lished) — standard for all external and wetted

metal parts

•

ASME BPE SF1 (20 Ra µin) mechanical finish,

non-electropolished and other finishes available

•

O

2

cleaning — optional

a

pplications

Ideal for biopharmaceutical and pharmaceutical

research and production facilities and equipment for

clean gas flow regulation.

•

High purity purge, or blanket gas

•

Sparge pressure regulation

•

Motive force for fluid movement

•

Clean air, N

2

, CO

2

, O

2

, AR

Sanitar

y V

alv

es

JSRLF

Series Low Flow Gas Reducing

V

alv

es