Steriflow Mark 96C Series User Manual

Mark 96c series, Sanitary pressure regulators (1/2"–1")

Steriflow by Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

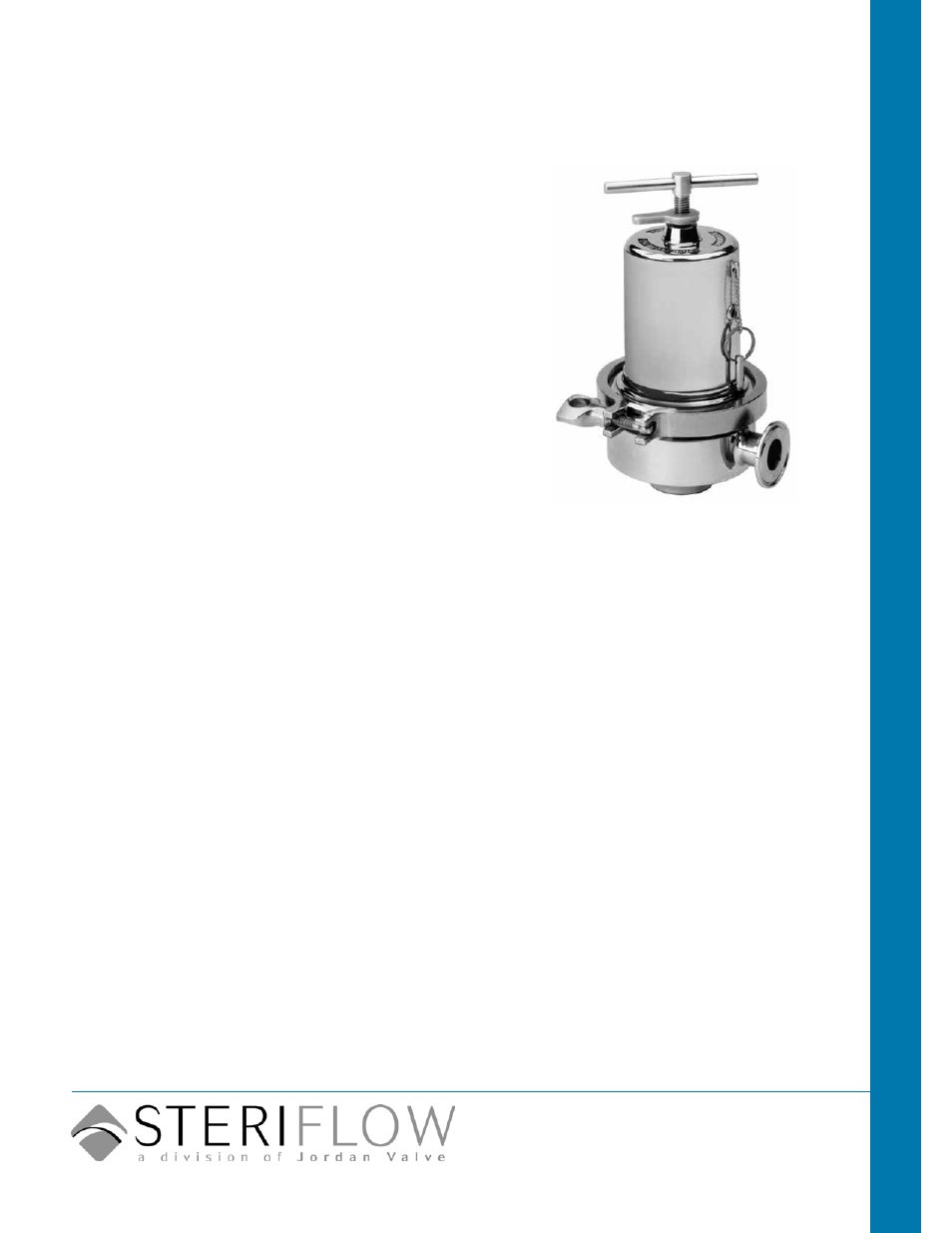

Mark 96C Series

Sanitary Pressure Regulators (1/2"–1")

The Mark 96C is a clamped body pressure reducing

valve designed to regulate downstream pressure of

process and utility applications in sanitary and aseptic

systems.

The Mark 96C operates by sensing pressure under the

diaphragm after the medium has entered the valve from

the bottom inlet port. As the downstream pressure ap-

proaches the set point, the force caused by the pressure

acting on the diaphragm overcomes the force of the

range spring, and the plug begins to move up toward

closed. This reduces the downstream pressure and

maintains the set point as the flow exits the valve from

the side port. If the pressure underneath the diaphragm

begins to fall, the spring forces the plug to move down

towards open, to allow the set point to be maintained.

F

eatures

• CRN Registration Number Available

• Soft seat capability for ANSI Class VI shutoff

• No guiding surfaces in the fluid – prevents particu-

late generation

• 100% 316L barstock body and metal trim

• Self-draining design

• No threads in contact with service media – prevents

accumulation of contaminants

• Easy to disassemble for cleaning

• Clean-in-Place, Steam-in-Place – dome lock pin to

allow CIP/SIP

• Jorlon diaphragm: A USP Class VI, FDA approved

PTFE based material which provides excellent chemi-

cal resistance, extremely long life in steam service.

Far superior to other elastomer or metal diaphragm

metals.

D

ocumentation

The following documentation is available, free of charge,

from our factory upon request at time of ordering:

• Traceable Material Certificates (free of charge for

body and ferrules)

• FDA or USP Class VI certificates on most soft seal

materials

• Final Test Reports

• Certificate of Surface Finish

• Certificate of Compliance/Certificate of Origin

a

vailable

F

inishes

Body

• Standard: 20 Ra mechanical finish and

electropolish on inside wetted surfaces;

machine finish and electropolish on exterior

• Optional: 20 Ra mechanical finish on

external surfaces; 8 Ra finish on internal or

external finishes

Stem

• Standard: 20 Ra mechanical finish and

electropolish

• Optional: 8 Ra finish

Spring Housing

• Standard: electropolished

• Optional: 20 Ra mechanical finish on exter-

nal surfaces; 8 Ra finish on external surfaces

on all sizes

Adjusting Screw

• Standard: electropolished

• Optional: 20 Ra mechanical finish; or 8 Ra

finish on non-thread portion

a

pplications

A wide variety of applications exist for the

MK96C in the pharmaceutical, biotech, health-

care, food & beverage and other industries.

The Mark 96C is suitable for liquid, gas and

steam service

Sanitar

y V

alv

es

Mark

96C Sanitar

y Pressure Regulat

ors

CRN Registration Number Available