Steriflow Mark 93 Series User Manual

Mark 93th series, Sanitary steam traps, Sanitar y v alv es mark 93th sanitar y steam traps

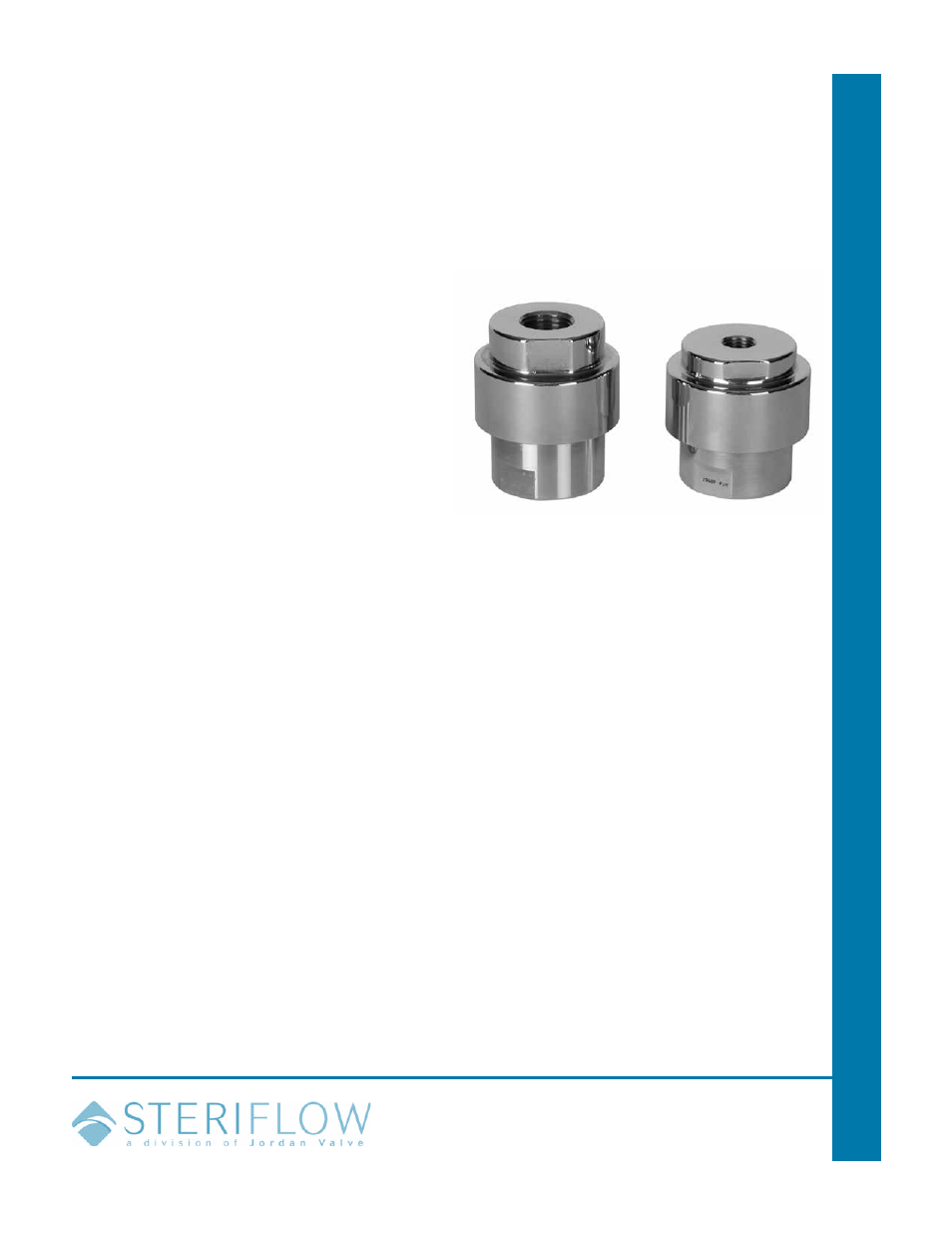

Mark 93TH Series

Sanitary Steam Traps

STERI

FLOW

TM

by Jordan Valve

3170 Wasson Road • Cincinnati, Ohio 45209

Telephone 513.533.5600 • Fax 513.871.0105

Toll-Free Telephone: 800.543.7311

[email protected] • www.steriflowvalve.com

Sanitar

y V

alv

es Mark

93TH Sanitar

y Steam

Traps

The Mark 93TH is a balanced port, thermostatic steam

trap designed for use in validated clean steam systems

that use threaded tube fittings or threaded tubing

adapters for connections. The sanitary design includes

a 20Ra

µin internal finish, self-draining design, and a

compact size.

The MK93TH is designed with the same bellows as our

MK93, and will therefore allow higher flow rates than

competitive designs. Note: Low subcooling operation

insures that condensate won’t back up and wet (cool)

the upstream validation temperature sensor.

There are two base designs within the MK93TH

product range: the standard MK93TH – good for inlet

pressures (P1) up to 50 psi (3,4 bar), and the MK93TH

Option “P” for the higher inlet pressure associated with

clean steam distribution drainage, or any application

with pressure ranging from 45 – 90 psi (3,1 – 6,2 bar).

Both designs are rated to 90 psi (6,2 bar) operating

pressure but are recommended for use within the

specified inlet pressure ratings.

Mark 93TH Operation

During heat-up, the bellows element is contracted and

fully open to discharge all non-condensable gas and

condensate. As recorded temperature rises, not as

much condensate is formed,and the temperature of

the condensate rises as the level in the upstream tub-

ing falls. This causes the bellows element to expand,

closing the valve. As condensate accumulates in the

body, the element cools, causing the bellows/stem tip

to retract allowing condensate to drain.

Features

•

Compact size makes it the ideal sanitary trap for

tight fitting process skid applications

•

Competitive lay-in dimensions allow in kind

replacement of troublesome existing installations

•

Low subcooling operation reduces probability

of temperature validation faults and resultant SIP

delays

•

Higher capacities and lower subcooling than com-

petitive designs allows faster heat-up.

•

All 316L stainless steel housing and

internals

•

Polished components – body interior is

mechanically polished to 20Ra finish

•

Self draining when installed vertically

(outlet side down)

•

Option for electropolished body

Applications

•

Typical applications are: temperature

validated sterilization drainage of fermen-

ters, bioreactors, separation and filtration

equipment, lyophilizers, autoclaves,

process piping equipment and steam

barriers.

•

Condensate drainage from clean steam

distribution lines

New: Compact Threaded Series