Steriflow Mark 968 Series User Manual

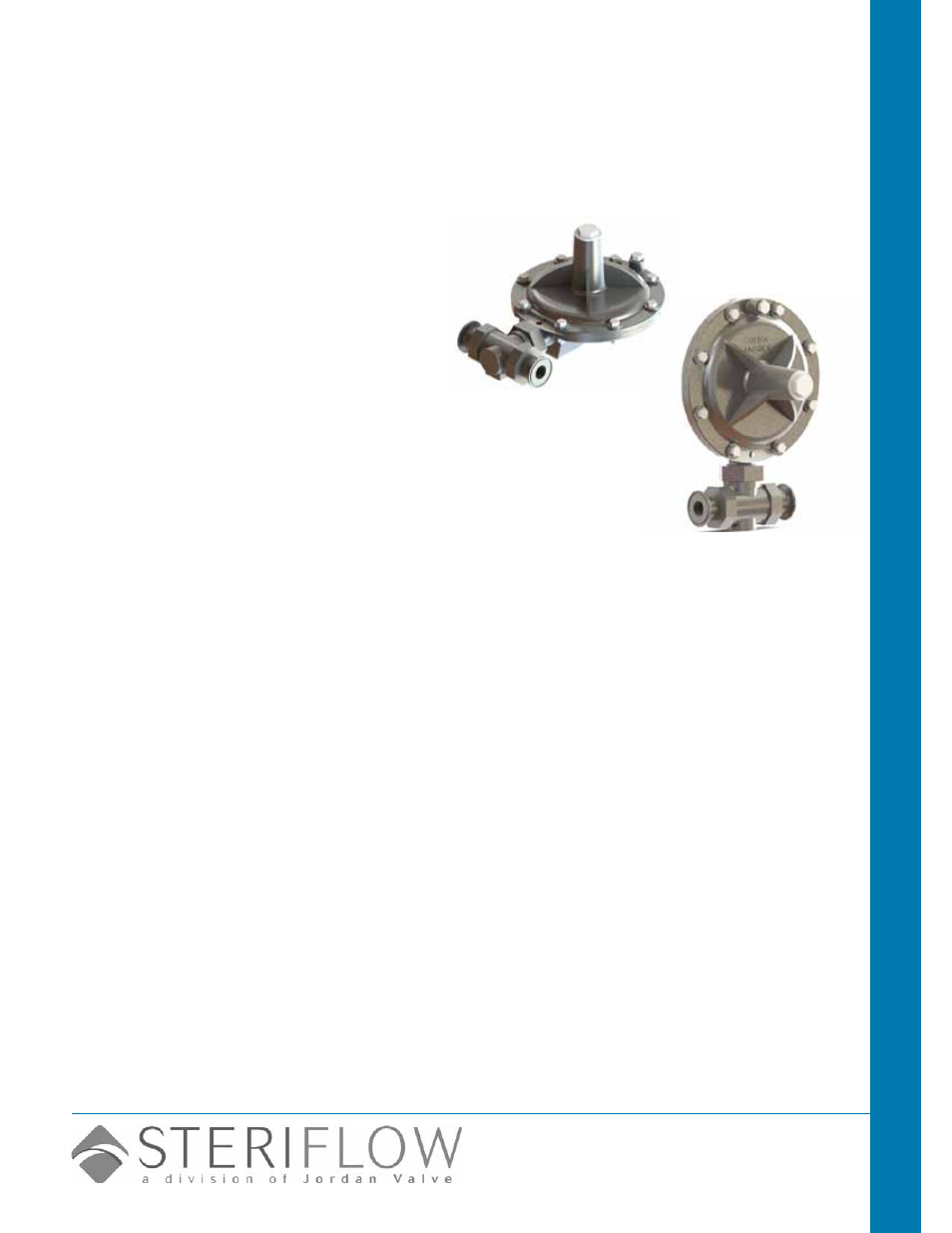

Mark 968 series, Gas regulat ors mark 968 sanitar y gas regulat or

Steriflow by Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

Mark 968 Series

Sanitary Gas Regulators sizes 3/4" - 2" for biopharm, pharma, food &

beverage low pressure Clean Dry Gas/Air blanketing and inline

pressure regulation

The Mark 968 Sanitary Gas Regulator is the ideal valve

for low pressure gas regulation in pharmaceutical and

food & beverage applications. The self-contained low

pressure gas regulator is for use on tank blanketing and

other very low critical pressure air and gas applications.

The Mark 968 is normally open. Increases in the outlet

pressure are sensed through the aspirator causing the

large elastomer diaphragm to rise, which moves the

plug toward the seat. As outlet pressure decreases, the

diaphragm moves down and moves the plug away from

the seat to increase flow. The lever, which connects the

stem to the diaphragm, amplifies diaphragm forces for

tighter shutoff (only available on sizes 3/4" and 1").

The large diaphragm and lever actuation allows the

Mark 968 to act with higher sensitivity compared to

smaller diaphragm pressure regulators. High sensitivity

is important, as the Mark 968 often works with very low

pressure (down to 1" w.c. or 2,5 mbar). This special

actuation improves the accuracy and shutoff of the valve

- two important benefits in this style of regulator.

Together, the SST construction, FDA-approved seals

and the tri-clamp connections make this valve well

suited for sterile gas applications and environments.

F

eatures

•

Inlet pressures up to 150 psi (10 bar)

•

Robust design — emergency outlet pressure may

reach 100% of inlet pressure without damaging

valve

•

360° body orientation — valve can be installed in

any position, and can be easily repositioned while

in-line

•

Easy maintenance — seat and plug can be in-

spected without removing body from the line

•

Completely self-operated — no external power

source required

•

Tight shutoff — soft elastomer plug provides ANSI

Class VI shutoff

•

316/316L SST body/trim and tri-clamp, quick dis-

connect clamp connection

•

FDA-approved seals and diaphragms

•

Optional electropolishing available

s

peciFications

Line Sizes:

3/4" (DN20) & 1" (DN25)

End Connections

•

Clamped — ISO/DIN or Tri Clamp

•

Flanged — 150#, 300#, PN25/40 & sterile flanges

Materials

•

Body & Housing: SA351 Gr. CF8M 316SS, OR

CF3M 316L

•

Seat: ASTM A479 316/316L

•

Plug: ASTM A479 316L and FDA-approved Viton

•

Diaphragm: Viton (FDA)

•

Aspirator Tube: FDA USP Class VI Teflon

Service:

Air or gas

Shutoff:

ANSI Class VI

Temperature Range:

-20°F (-29°C) to 200°F (93°C)

Maximum Inlet Pressure:

150 psi (10 bar)

Reduced Pressure Control Range:

•

1.0 to 2.5 inches w.c. (2,5 to 6,2 mbar)

•

2.0 to 5.5 inches w.c. (5,0 to 13,7 mbar)

•

4.0 to 10.0 inches w.c. (10,0 to 24,9 mbar)

•

5.0 to 30.0 inches w.c. (12,4 to 74,7 mbar)

•

0.5 to 1.75 psig (0,03 to 0,12 bar)

•

1.0 to 3.5 psig (0,07 to 0,24 bar)

Orifice Sizes (Interchangeable):

1/8" (3mm), 3/16"

(5mm), 1/4" (6mm), 5/16" (8mm), 3/8" (10mm), 7/16"

(11mm), 1/2" (13mm), 9/16" (14mm)

Gas Regulat

ors

Mark

968 Sanitar

y Gas Regulat

or