Steriflow Mark 978INLINE Series User Manual

Mark 978 series, Sanitary control valves - jd version

Steriflow by Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

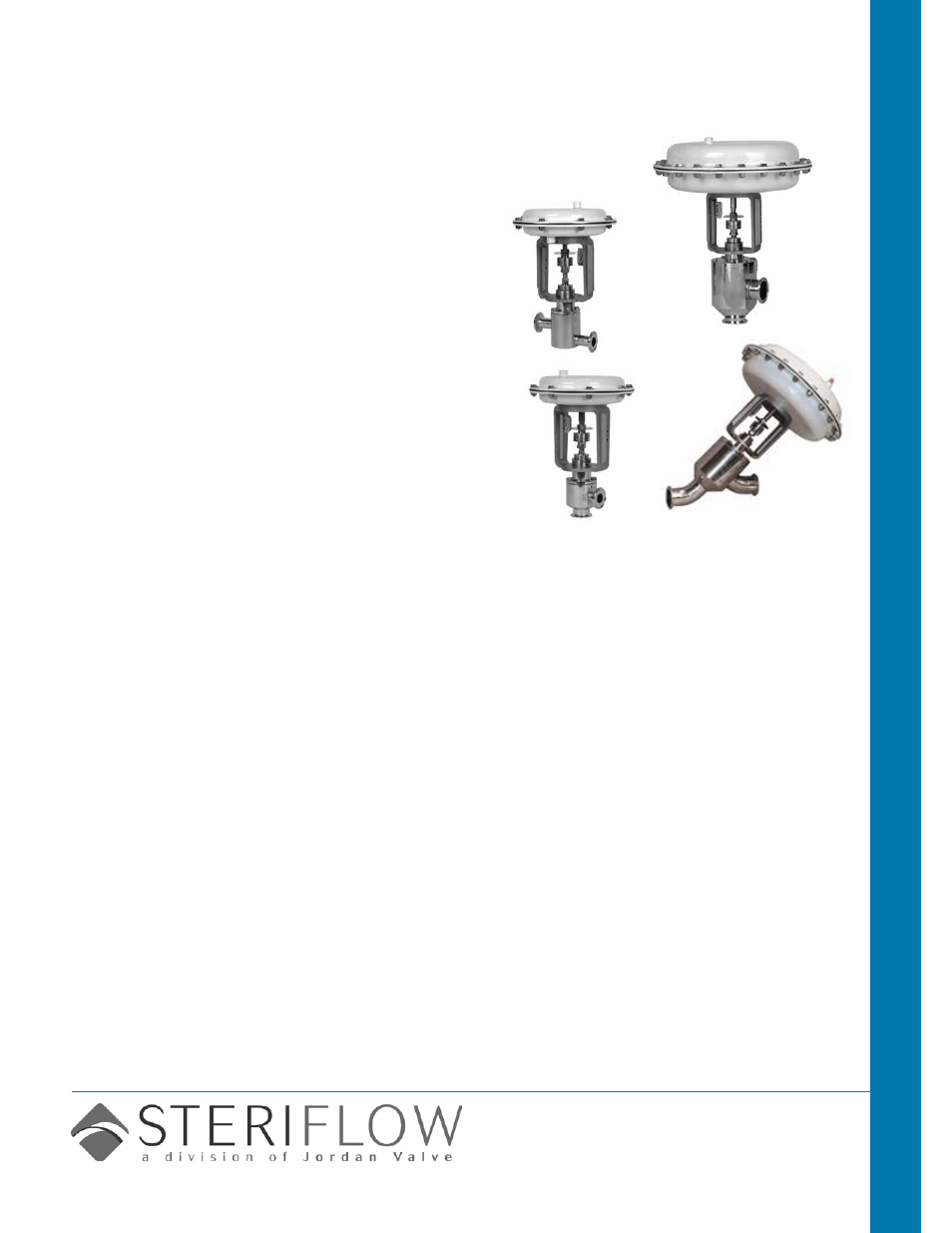

Mark 978 Series

Sanitary Control Valves - JD Version

The Mark 978-JD (Jorlon Diaphragm) Series is de-

signed to meet the rigid specifications for sterile process

and clean utility control valves. This valve series is

suitable for a wide variety of applications in the, bio-

pharmaceutical, Parenteral, cosmetic, dairy and food

and beverage industries.

The Mark 978 meets ASME BPE 2009 guidelines, and

is ideally suited for a wide range of flowing media in

both the clean utility and process areas of sanitary and

aseptic systems.

High rangeability, true characterized trim, high capaci-

ties, superior temperature and pressure ratings, facili-

tated by a superior diaphragm, make the MK978 the

sanitary control valve for sterile process, buffer, WFI

and acid metering, and clean gas and steam services.

Whether the need is to control pressure, temperature,

flow, pH, or another variable, the MK978 is the right

valve for your process.

F

eatures

• Specialized design of diaphragm seal and compo-

nents allows ultra-high cycle life and lifetime

diaphragm warranty

• Jorlon diaphragm – highest continuous steam pres-

sure ratings on the market, full CIP/SIP capabilities

• FDA & USP Class VI compliance standard on all

process seal and seat materials

• Self draining – Angle Body: when mounted in vertical

(all sizes) or horizontal orientations (except 3"); IN-

LINE: 1", 1-1/2" & 2" when mounted in horizontal line

• No guiding in the wetted area – prevents particulate

generation

• Mechanically polished internal components – 20Ra

(0,5 µm) finish, electropolish – standard; , 8Ra

optional.

• Wetted parts made of 100% ASTM A479 316L

Stainless Steel barstock

• Maintenance-friendly – easy to perform sanitary

maintenance with simple disassembly and reassembly

• Steel, baked corrosion resistant coated multi-spring

actuators to meet a wide range of differential pres-

sure requirements while providing excellent corro-

sion resistance during washdown

a

vailable

F

inishes

Body

• Standard: 20 Ra mechanical finish on

internal wetted surfaces (0,5 µm); machine

finish on exterior (63 RMS), and electropol-

ished inside and out

• Optional: 20 Ra mechanical finish on

external surfaces (0,5 µm); 8 Ra finish on

internal or external surfaces (0,2 µm)

Stem

• Standard: 20 Ra mechanical finish and

electropolish (0,5 µm)

• Optional: 8 Ra mechanical finish (0,2 µm)

a

pplications

A wide variety of applications exist for the MK978

in the pharmaceutical, biotech, health care, and

food & beverage and other industries including:

Processes

• Fermenter

• Bioreactor

• Lyophilization

• Chromatography

• SIP/CIP Systems

• Parenteral filling

Sanitar

y V

alv

es

Mark

9

78JD Sanitar

y Control

V

alv

es

Media

• Bio-process

• Caustic

• Acids

• Buffer

• Clean Steam

• WFI

CRN Registration Number Available