Steriflow Mark 958 Series User Manual

Mark 958 series, Sanitary gas back pressure regulators

Steriflow by Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

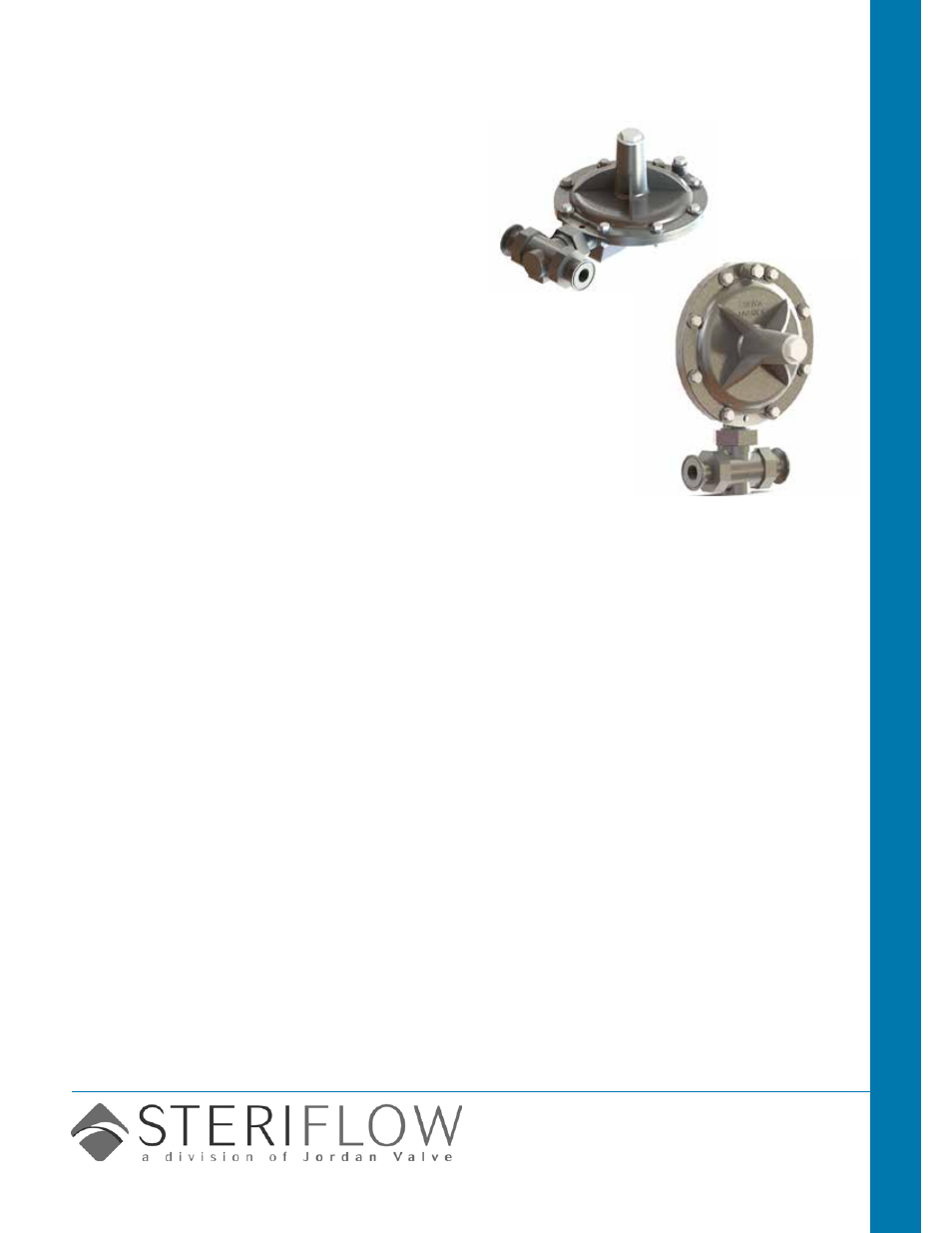

Mark 958 Series

Sanitary Gas Back Pressure Regulators

(3/4" - 1")

The Mark 958 Sanitary Gas Back Pressure Regu-

lator is the ideal valve for low back pressure gas

regulation for blanketing, motive force, or low

pressure sparging in pharmaceutical and food &

beverage applications.

The Mark 958 works in conjunction with the Mark

968 (or other) Pressure reducing valve in these ap-

plications. The Mark 958 can be used to vent gas

from a vessel to prevent the pressure from rising to

a level that could damage the vessel, or cause pro-

cess upset, while maintaining a small constant flow

(if desired) to keep the gas fresh. During vessel

filling - this regulator will be required to open wide

to allow enough gas to escape as the vapor space

in the tank grows smaller. To size properly, the rate

of fill must be known so that a regulator can be

chosen based on its ability to relieve the required

amount of gas while sustaining desired blanketing

pressure. The Mark 958 will also work well in any

other type of low back pressure gas application.

The large diaphragm and lever actuation allows the

Mark 958 to act with higher sensitivity compared to

smaller diaphragm pressure regulators. High sen-

sitivity is important, as the Mark 958 often works

with very low pressure (down to 2" w.c. / 5,0 mbar).

This special actuation improves the accuracy and

shutoff of the valve - two important benefits in this

style of regulator. Together, the SST construction,

FDA-approved seals and the tri-clamp connections

make this valve well suited for sanitary applications

and environments.

F

eatures

• Body rating up to 150 psi (10,3 bar)

• Robust design - emergency outlet pressure

may reach 100% of inlet pressure without dam-

aging valve

• 360° body orientation - valve can be installed

in any position, and can be easily repositioned

while in-line

• Easy maintenance - seat and plug can be in-

spected without removing body from the line

• Completely self-operated - no external power

source required

Sanitar

y V

alv

es

Mark

95

8 Sanitar

y Gas Back

Pressure Regulat

ors

s

peciFications

Line Sizes:

3/4" (DN20) & 1" (DN25)

End Connections

•

Clamped — ISO/DIN or Tri Clamp

•

Flanged — 150#, 300#, PN25/40 & sterile flanges

Materials

•

Body & Housing: SA351 Gr. CF8M 316SS, OR

CF3M 316L

•

Seat: ASTM A479 316/316L

•

Plug: ASTM A479 316L and FDA-approved Viton

•

Diaphragm: Viton (FDA)

•

Aspirator Tube: FDA USP Class VI Teflon

Service:

Air or gas

Shutoff:

ANSI Class VI

Temperature Range:

-20°F (-29°C) to 200°F (93°C)

Maximum Inlet Pressure:

150 psi (10 bar)

Reduced Pressure Control Range:

•

2.0 to 6.0 inches w.c. (5,0 to 15,0 mbar)

•

3.0 to 11.0 inches w.c. (7,5 to 27,4 mbar)

•

5.0 to 35.0 inches w.c. (12,4 to 87,0 mbar)