Steriflow JSR Series User Manual

Jsr series

Steriflow by Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

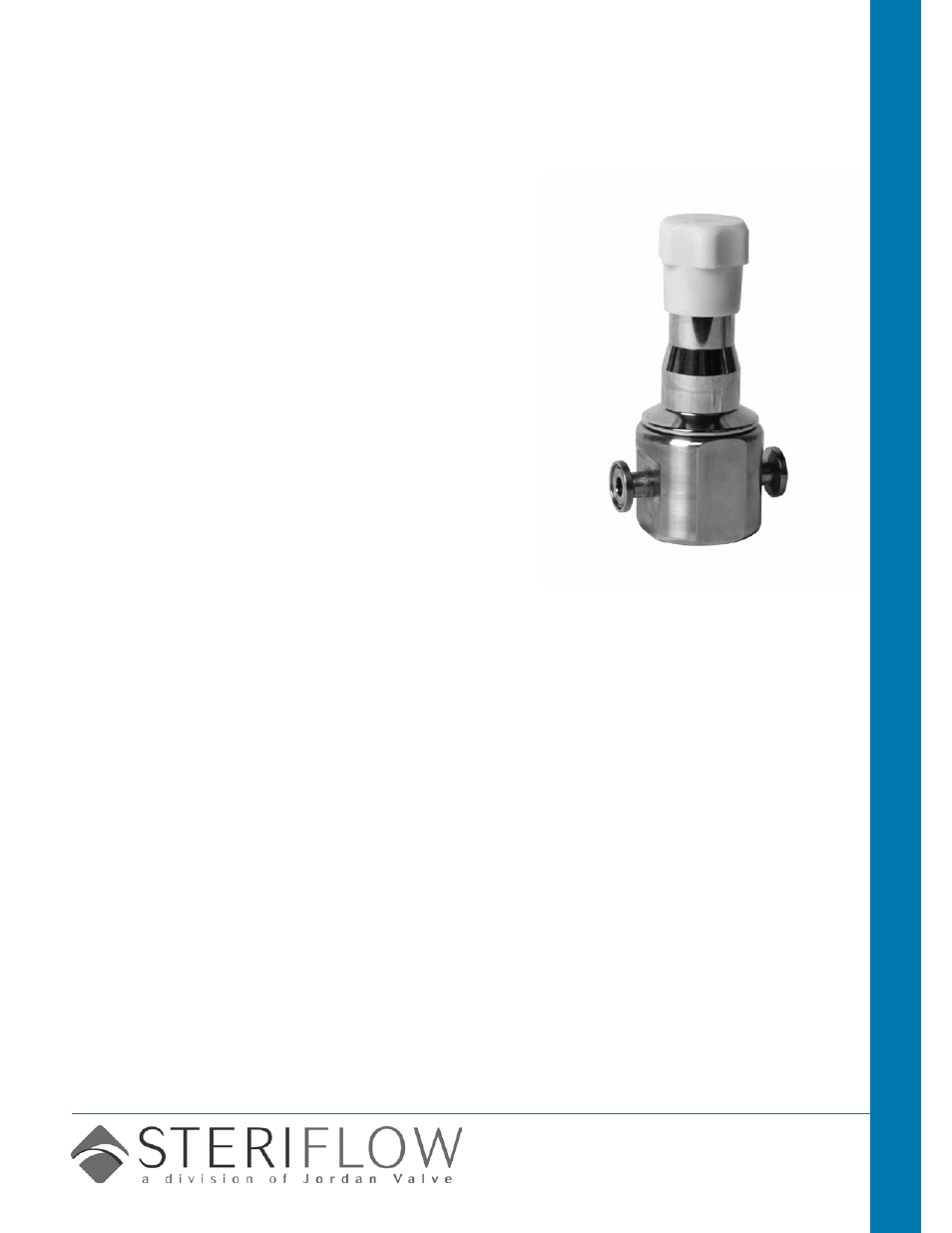

JSR Series

High Purity Bio-Pharma Gas Pressure Reducing Valves

JSR is the first high purity gas pressure regulator designed and

built specifically for hygienic, ASME BPE gas applications.

Traditionally, manufacturers adapted their industrial gas

regulators for use in biopharm by simply changing the con-

struction materials and surface finish. Not so with the JSR.

It's been designed specifically to eliminate the exposed

threaded connections and permanent contaminant traps

below the diaphragm. And, it features an in-line removable

trim set to facilitate quick trim change out and cleaning with-

out valve removal or disassembly.

The durable valve body and metal trim components are

machined from ASTMA479 316L SST barstock and fin-

ished to ASME BPE SF5 (20Ra micro-inch, electropolished)

standard. The valve is outfitted with the rugged Jorlon dia-

phragm and Teflon, PEEK, or EPDM seats and seals that

are all FDA approved, USP Class VI compliant materials.

These materials of construction enable JSR to withstand the

rigors of SIP and CIP processes if required. And, the new

EPDM seat reduces lockup to less than 2.5 psig.

F

eatures

• No exposed threaded connections below diaphragm

• In-line removable seat and trim facilitate cleaning and

maintenance

• Barstock construction guarantees material integrity and

surface finish

• High flow rate coupled with high rangeability reduces

need for reduced trim sizes

• Minimized internal volume

• Proprietary Jorlon diaphragm material provides excep-

tionally long life and CIP/SIP capability

• Soft seat material for ANSI Class VI shutoff

• Can be used on continuous clean steam, and on non-

cavitating fluids.

D

ocumentation

The following documentation is shipped with each order:

• Steriflow Unicert

— Traceable Material Heat Number for body and

ferrules

— Certificate of Compliance to FDA and USP

Class VI

Certificate of Surface Finish

• Final Test Reports and Certificate of Origin available

upon request at time of order

s

urFace

Finish

• ASME BPE SF5 (20Ra µ in (0,5 µm),

electropolished) – standard for all

external and wetted metal parts

• Other finishes optional

• O

2

cleaning - optional

a

pplications

Ideal for clean gases typically found in bio-

pharmaceutical, pharmaceutical and food &

beverage processes including:

• Clean Filter Air

• Nitrogen

• Carbon Dioxide

• Argon

• Oxygen

• Custom purge or blanket gas

Sanitar

y V

alv

es

JSR Series Ultra

-High Pressure Reducing

V

alv

es

CRN Registration Number Available