9300 servo plc, System blocks, 3 oc5 − i x t overload monitoring – Lenze Drive PLC Developer Studio 9300 Servo PLC (V8.x) User Manual

Page 81

9300 Servo PLC

System blocks

2.12

MCTRL_MotorControl (node number 131)

2−67

L

9300 Servo PLC EN 5.0

2.12.17.3

OC5 − I x t overload monitoring

Error

Monitoring function

System variable

Possible responses

No.

Display

TRIP

Message

Warning

FAIL−QSP

Off

x015 OC5

I x t overload

MCTRL_bIxtOverload_b

·

· Lenze setting

ü Setting possible

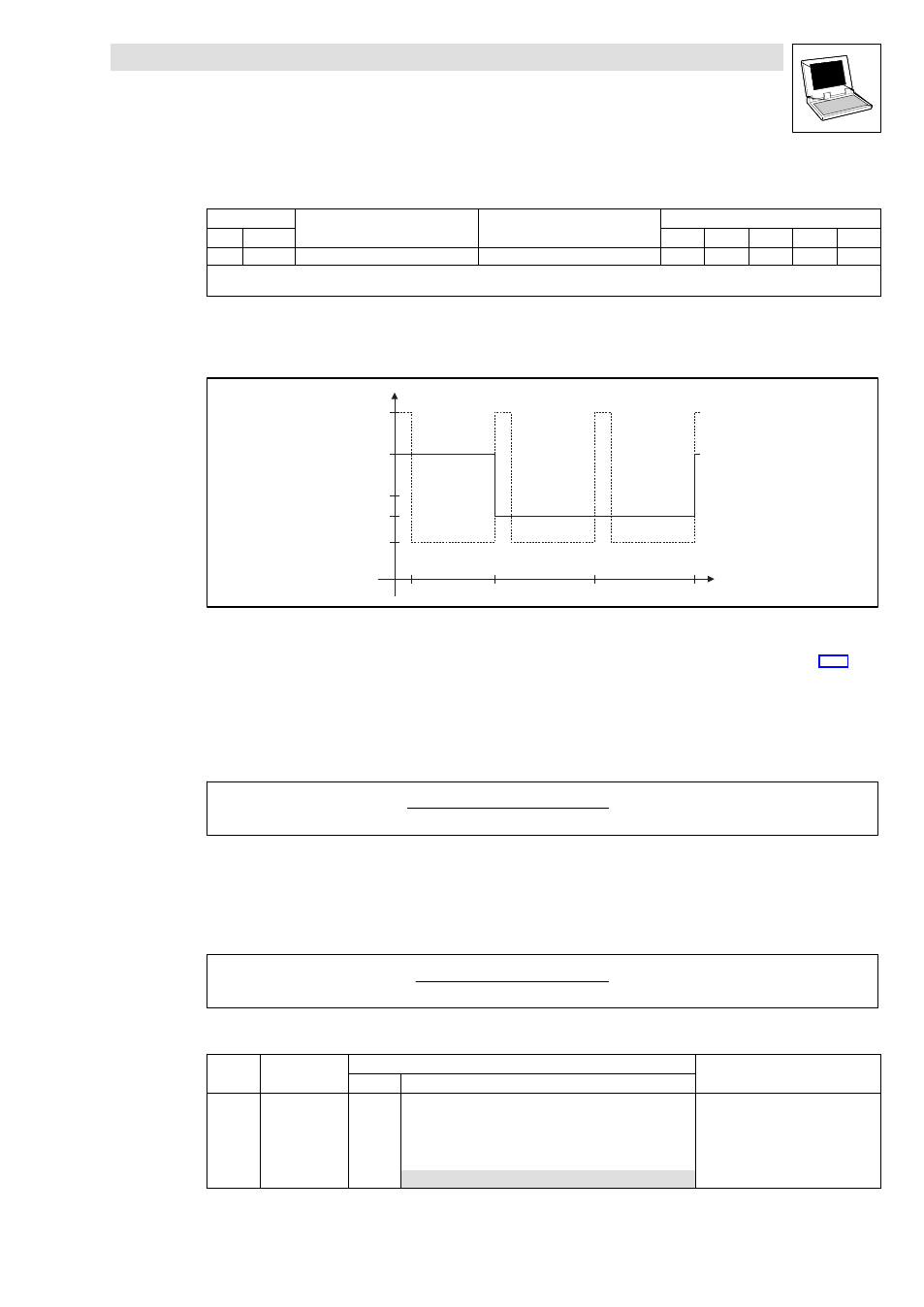

Overcurrent diagram for OC5 fault message

The following diagram shows the maximum permissible overcurrent as a function of time:

150

100

75

200

I

[%]

Motor

10

60

120

180

t [s]

44

Fig. 2−27

Overcurrent diagram

The maximum permissible overcurrent is dependent on the I

max

limit set under C0022.

(

^ 2−60)

I

max

limit sender under C0022

£

150 % I

N

:

·

Within a period of 180 s, the arithmetic mean value of the motor current may not exceed 100

% of the rated device current.

·

Example: Arithmetic mean value to curve

:

60 s

@ 150 % ) 120 s @ 75 %

180 s

+ 100 %

I

max

limit set under C0022 > 150 % I

r

:

·

Within a period of 60 s, the arithmetic mean value of the motor current may not exceed 70 %

of the rated device current.

·

Example: Arithmetic mean value to curve

:

10 s

@ 200 % ) 50 s @ 44 %

60 s

+ 70 %

The current controller load is displayed in C0064:

Code

LCD

Possible settings

IMPORTANT

Lenze

Selection

C0064 Utilization

g

Controller load I x t during the last

180 seconds

·

C0064 >100 % trips OC5.

·

TRIP−RESET is only possible if

C0064 < 95 %.

0

{1 %}

150