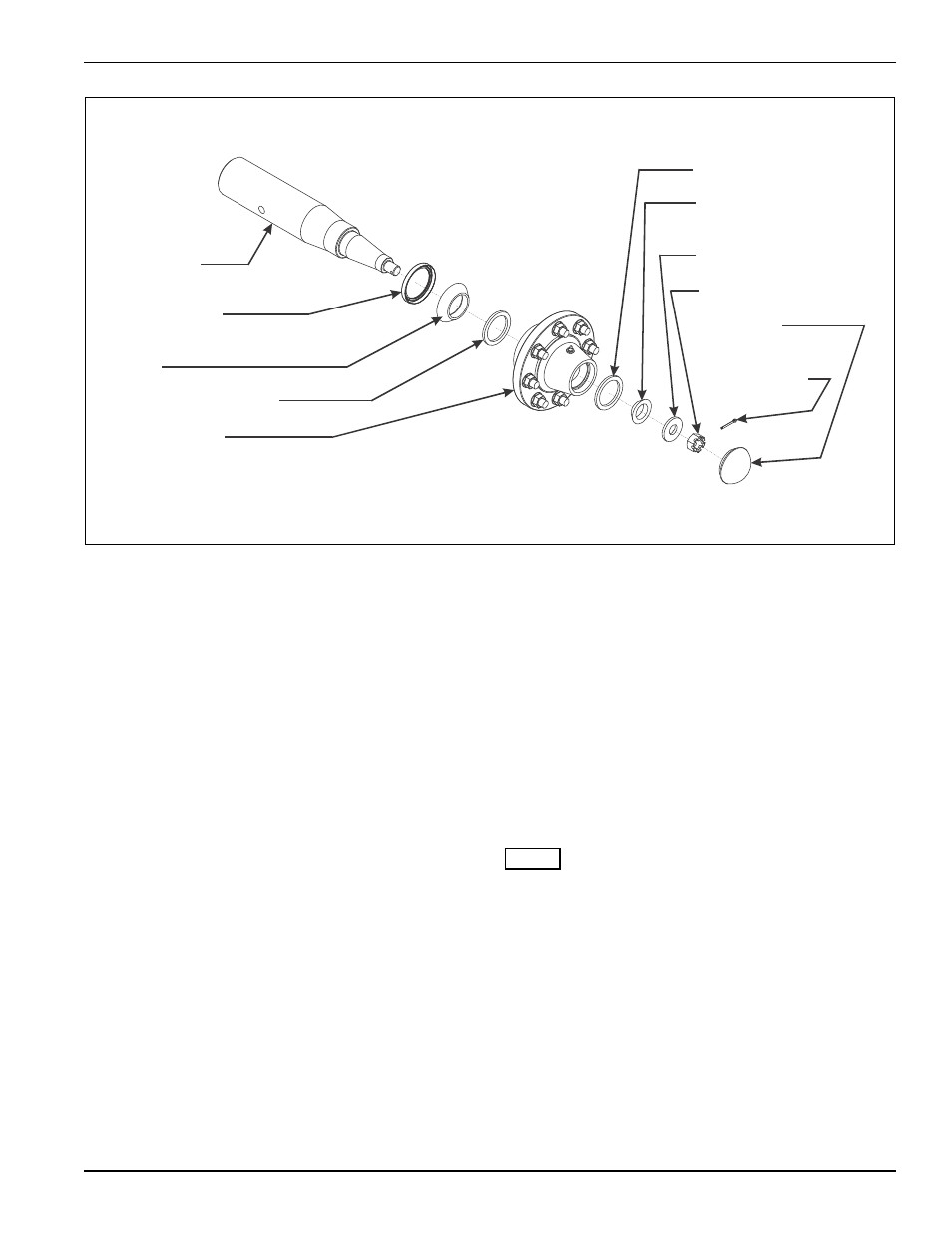

Figure 4-12: wheel bearing maintenance, Wheel bearing maintenance – Landoll 2430 Weatherproofer I User Manual

Page 67

OPERATION AND MAINTENANCE

4-9

Figure 4-12: Wheel Bearing Maintenance

Wheel Bearing Maintenance

Wheel bearing maintenance should be performed at the

beginning of every season of use. Check the wheel

bearings periodically for excessive end play. If needed,

adjust or replace them using the following procedure:

1.

Place the frame on blocks or stands sufficient to lift

the tire clear of the ground.

2.

Remove the tire.

3.

Remove the hub cap, cotter pin, slotted nut and

washer (See Figure 4-12.)

4.

Remove the hub. Clean and inspect the bearings and

hub cavity. Replace any worn or defective parts.

5.

Repack the bearings using a high-quality wheel

bearing grease.

6.

Slide the seal(s) onto the spindle. Do not install the

seal into the hub.

7.

Slide the inner bearing cone and hub onto the

spindle.

8.

Install the outer bearing cone, washer and slotted

nut.

9.

Tighten the slotted nut while rotating the hub until

there is a slight resistance to wheel rotation. Then,

back the slotted nut off one notch, until the wheel

rotates freely without end play.

10. Slide the triple-lip seal to the hub and install the seal

in the hub.

NOTE

The triple-lip seals should point away from the hub to

keep contaminants out and allow grease to pass.

11. Install a new cotter pin and replace the hub cap.

2430 wheel bearing maintenance

SPINDLE

TRIPLE LIP

GREASE SEAL

INNER BEARING

CONE

INNER BEARING CUP

8 BOLT HUB

OUTER BEARING CUP

OUTER BEARING

CONE

SPINDLE WASHER

1-14 HEX SLOT NUT

HUB CAP

3/16 X 1-1/2

COTTER PIN