Sid242 chapter 3, Chapter 3 sqs-242 software, 0 introduction – INFICON SID-242 Thin Film Deposition Controller User Manual

Page 31

Chapter 3 SQS-242 Software

3-1

3.0 Introduction

The SQS-242 Deposition Control Software works with Sigma Instrument’s SQM-242

Card to provide an inexpensive, yet powerful, PC based Thin Film Deposition Controller

that can:

Measure up to eight quartz crystal sensors simultaneously

Control up to four deposition source supplies simultaneously

Codeposit up to four films with preconditioning, multiple rate ramps, and

feed/idle phases

Graph deposition rate, rate deviation, or power output

Store process, film and material parameters in Microsoft Access

®

database

Use inexpensive PLCs for flexible and reliable external process controls

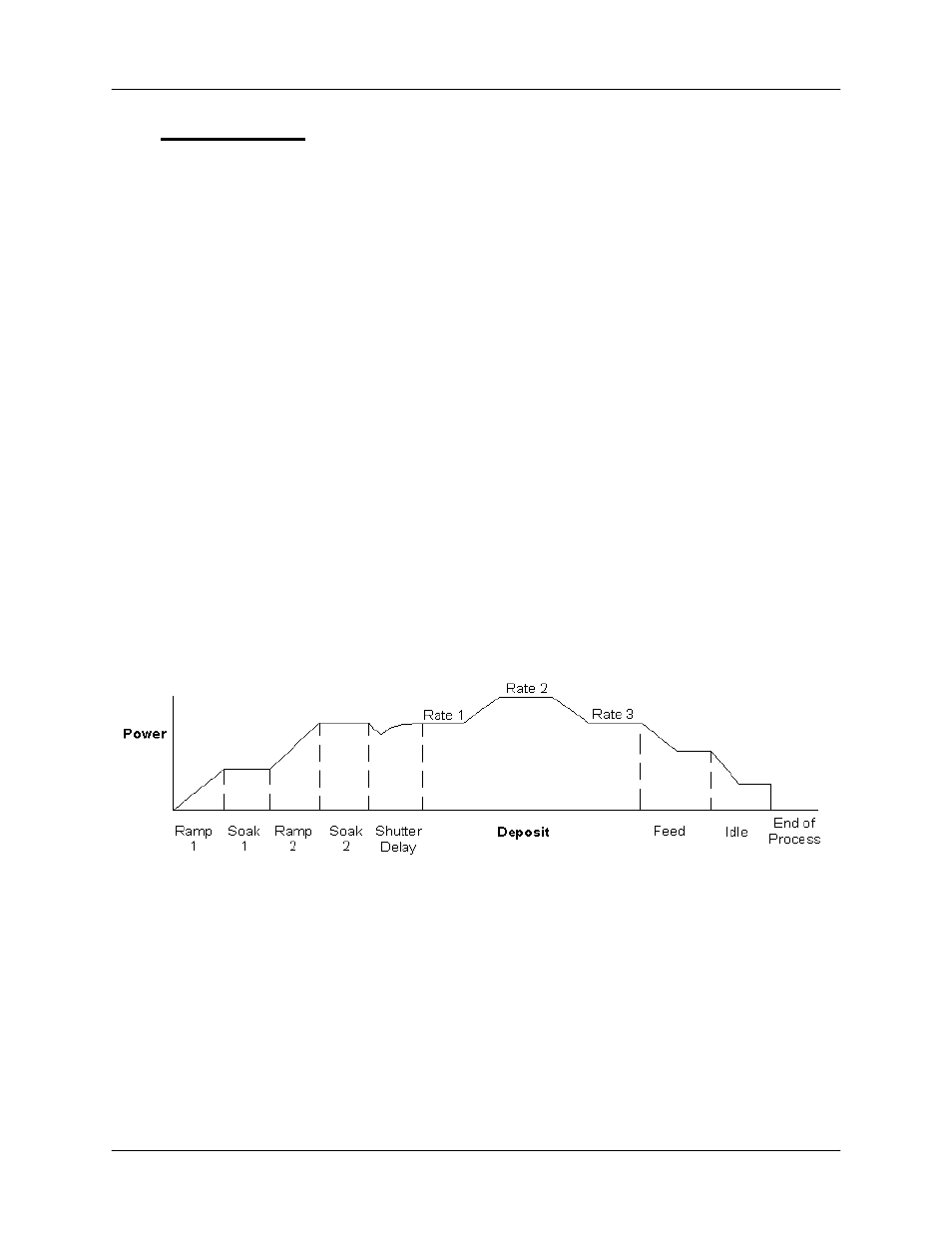

A typical deposition cycle for a thin film is shown below. The cycle can be broken into

three distinct phases: pre-conditioning (ramp/soak), deposition, and post-conditioning

(feed/idle). During pre-conditioning, power is supplied to prepare the source material for

deposition. When pre-conditioning ends, material deposition begins. During deposition,

the PID loop adjusts the evaporation source power as required to achieve the desired

deposition rate. When the desired thickness is reached, the evaporation source is set

to feed or idle power. At this point the process may be complete, or deposition of

another film layer may begin. If desired, up to four separate films can be codeposited

within a single layer. There is no limit to the total number of layers.

The SQS-242 software allows you to build the recipes and perform the operating

functions required to control all aspects of multi-layer thin film deposition. Process

recipes are stored in Microsoft Access format. There is no practical limit to the number

of processes, films, or materials that can be stored in the database.