Troubleshooting, Operator reference chart – ERICO LENTON Mid-Range Bar Threader User Manual

Page 23

www.erico.com

23

1. If the LENTON bar threader will not start,

check the following:

a. Check that the machine is plugged in and the

power is on.

b. Machine hood must be in the forward position.

c. The correct electrical power must be used.

See “Electrical” section.

2. If the cutting oil is not flowing to the

cutting head, check the following:

a. Oil level – see “Add Oil” section.

b. Please make sure your chip drawer and reservoir

is empty of chips.

c. If you are having electrical problems please call

LENTON Service Group.

3. If the motor is stalling during threading,

check the following:

a. Improper machining step – see “Threading

Operation” section.

b. Proper voltage – see “Electrical” section.

c. Proper cutting speed.

d. Bar loose in the vise.

e. Chaser wear.

f. Bent bar ends.

Troubleshooting

4. If the chasers are wearing prematurely,

check the following:

a. Improper oil flow.

b. Harder than normal rebar.

5. If the bar threader will not engage the rebar,

check the following:

a. Is the bar stop moved out of the way.

b. Proper rotation of the cutting head –

see “Electrical” section.

c. Improper first pass machining step –

see “Threading Operation” section.

6. If the bar ends have stripped threads,

check the following:

a. Are the chaser holders in the correct position –

see “Change Chasers and Holders” section.

b. Are the woodruff keys tight in the slot –

see “Change Chasers and Holders” section.

c. Chaser wear.

7. If the chaser holders will not shift in the

cutting head, check the following:

a. Chips, dirt or other contaminants in the

cutting head.

b. Bent control rod.

c. Damaged control key.

d. Damaged control block.

e. Chaser holder(s) protruding beyond face

of cutting square.

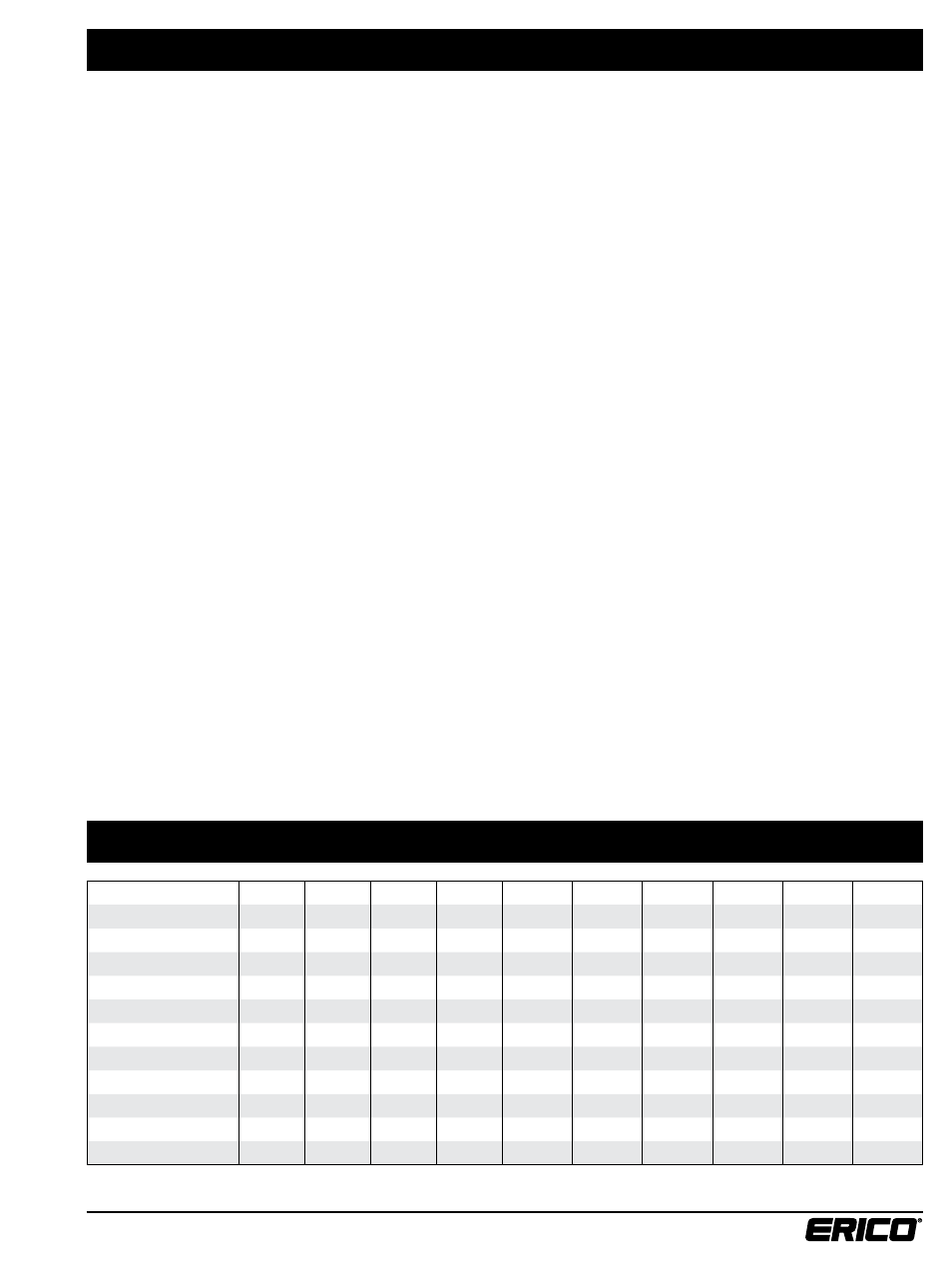

Bar Size Number

4

5

6

7

8

9

10

11

14

18

Bar Size Metric

12 mm

16 mm

20 mm

22 mm

25 mm

28 mm

32 mm

36 mm

43 mm

57 mm

Chaser Holder Set

101D

101D

111D

111D

111D

111D

111D

111D

121D

131D

Bar End Gauge

ELBEG12A ELBEG16A ELBEG20A ELBEG22A ELBEG25A* ELBEG28A* ELBEG32A* ELBEG36A* ELBEG43A* ELBEG57A*

Control Key

ELK12

ELK16

ELK20

ELK22

ELK25

ELK28

ELK32

ELK36

ELK43

ELK57

Control Block

E2

E2

E2

E2

E2

E2

E2

E2

A2

A2

Guide Rings Standard

12D

16B

20A

22A

25A

28A

32A

36A

43A

57A

Guide Rings Large

12E

16C

20B

25A

25B

28B

32B

36B

43B

57B

Guide Rings Extra Large

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

43C

57C

No. of Threading Steps

1

1

2

2

2

2

2

3

4

4

Operating Speed

High

High

High

High

High

High

High

High

Low

Low

Spring Size

Blue

Blue

Blue

Blue

Blue

Blue

Blue

Blue

Red

Red

Operator Reference Chart

* Note: Bar end gauges with suffix “HT” may be substituted.