Checking threads and bar end engagement – ERICO LENTON Mid-Range Bar Threader User Manual

Page 21

www.erico.com

21

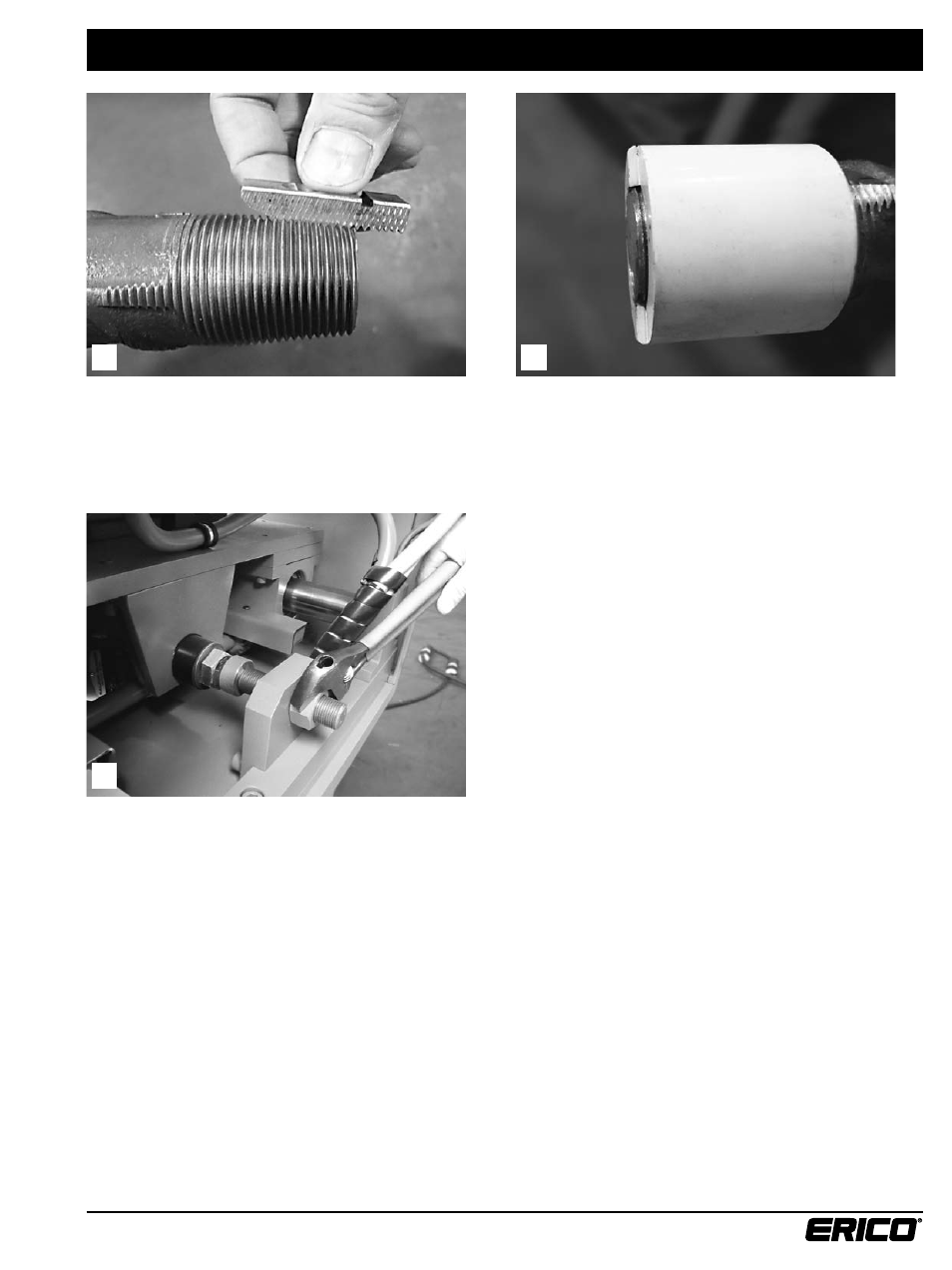

The thread profile should be checked with a

brand new chaser.

To check the bar end diameter after threading slide the

bar end gauge over the bar and look to see if the end of

the bar falls within the step range of the gauge.

Checking Threads and Bar End Engagement

If the diameter of the bar is off, the adjustment screw is used to

make up the difference. The adjustment screw is located at the

back of the machine. Turning it in, increases the bar end diameter,

turning it out, decreases the diameter.

If the diameter of the bar is off, the proper adjustment can very

easily be made by measuring the amount of protrusion from or

recession into the gauge.

Example: If the bar is protruding beyond the gage by 1/8 inch you

would turn the adjustment screw in (clockwise) so that the machine

body would move forward 1/8 inch. If the bar was 1/8 inch too

short you would turn the screw out (counter-clockwise) moving

the body of the machine back 1/8 inch.

A scrap piece of bar should be used to set the bar end

gauge prior to making a production run.

2

1

3

- 6Z34VF14 Rod Hanging Basket Tray Clip (1 page)

- 766PM Far Side Box Support (1 page)

- 766PMD Far Side Box Support (1 page)

- CADDY MPVTI Low Voltage Mounting Clip (2 pages)

- H-Series CADDY PYRAMID Support System (3 pages)

- CADDY PYRAMID RL, PIPE RETAINERS (2 pages)

- CADDY PYRAMID Rooftop Equipment Support (4 pages)

- CADDY PYRAMID Single Post Support (1 page)

- CADDY PYRAMID TF Series, Fixed Height Tool-Free Supports (2 pages)

- CADDY ROD LOCK Anchor Screw (2 pages)

- CADDY ROD LOCK Beam Clamp (2 pages)

- CADDY ROD LOCK Channel Nut (2 pages)

- CADDY ROD LOCK L-Bracket (2 pages)

- CADDY ROD LOCK Strut (2 pages)

- CADDY SPEED LINK Riveted Accessories (4 pages)

- CADDY SPEED LINK SLK-Keyless Locking Device and Bulk Cable (2 pages)

- CADDY SPEED LINK SLK-Keyless Locking Devices (2 pages)

- CADDY SPEED LINK-Accessory Cables (1 page)

- CADDY SPEED LINK-SLK Cable End Accessories (4 pages)

- TSGB Series Screw Gun Bracket (2 pages)

- GLIDER Electrical Box Attachment (2 pages)

- H Series-Electrical Box Bracket (2 pages)

- ROD LOCK Plywood Pre-set Anchor (2 pages)

- ROD LOCK Strut End Bracket (2 pages)

- ROD LOCK Strut (2 pages)

- CADDY ROD LOCK Strut Nut (2 pages)

- CER4 Cable from Stud (2 pages)

- High Performance CADDY CAT HP J-Hook Assemblies (6 pages)

- KBT Wire Basket Tray Clip (1 page)

- MPCB1220 (2 pages)

- SBC Series, Beam Clamp, 3/8" and M10 (1 page)

- TSR200 Telescoping Strut Replacement Bracket (2 pages)

- TSRBS1625 Telescoping Box (3 pages)

- Universal Pedestal Clamp (2 pages)

- Branch Line Restraint Device (2 pages)

- Branch Line Restraint Strucural Attachment Fitting for Steel 12 gauge (2 pages)

- Branch Line Restraint, Structural Attachment Fitting for Concrete or Wood (2 pages)

- Branch Line Restraint, Structural Attachment Fitting with 3/8"-16 male thread" (2 pages)

- 510 CADDY EZ RISER (2 pages)

- 429 CADDY MACROFIX PLUS NI (1 page)

- Seismic Hanger Clamps (3 pages)

- CADDY PYRAMID Equipment Supports (3 pages)

- CADDY ROD LOCK Bottom-Mount Duct Bracket (2 pages)

- Bottom-Mount Duct Bracket, Narrow (2 pages)

- Top-Mount Duct Bracket (2 pages)